Preparation method of konjac glucomannan-gelatin based capsule

A technology based on konjac glucomannan and gelatin, which is applied in capsule delivery, medical preparations of non-active ingredients, pharmaceutical formulas, etc., can solve the problems of excess production capacity, complicated preparation process, and high price of gelatin, and achieve strong elasticity, Uniform thickness and less air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

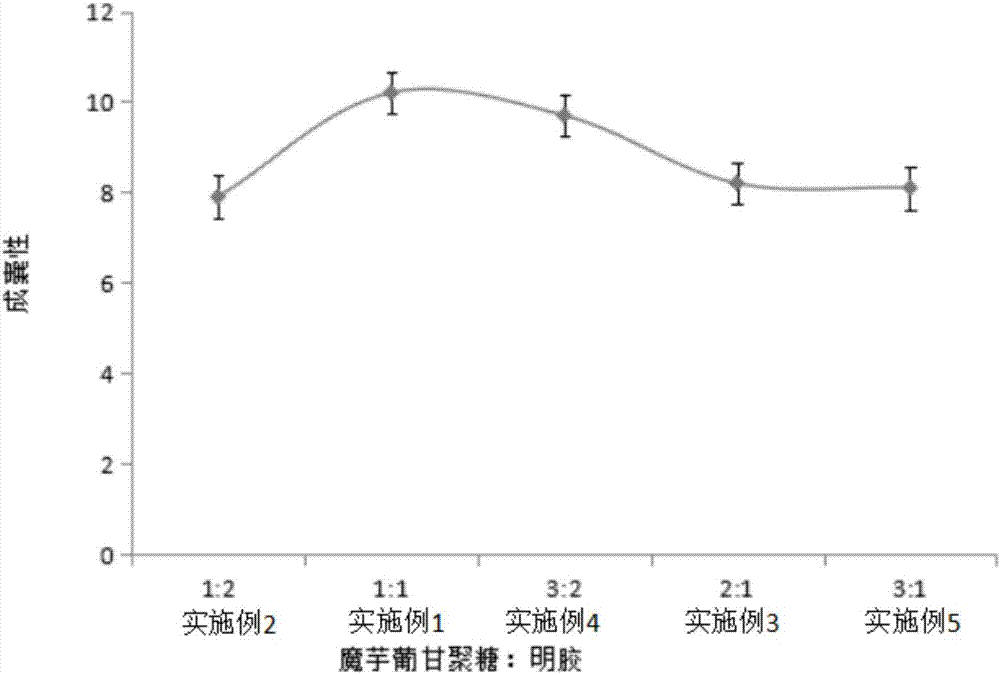

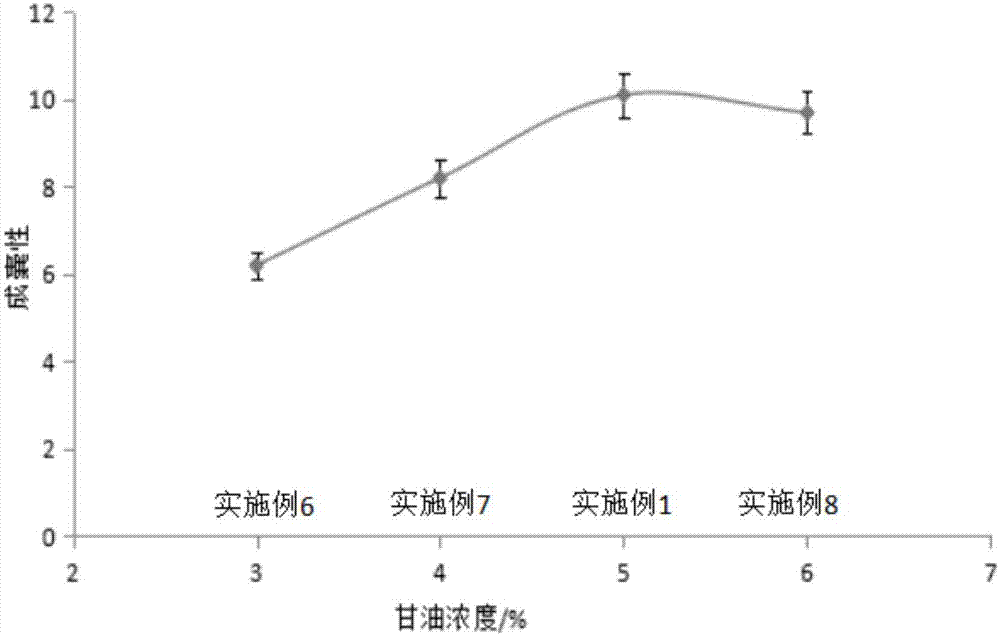

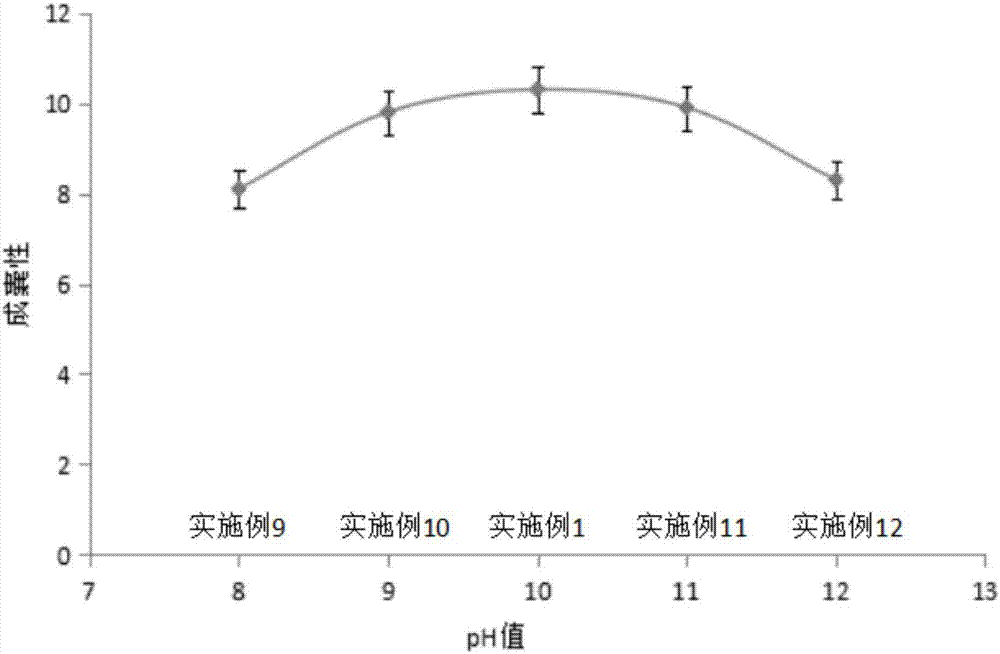

Embodiment 1

[0034] A preparation method of konjac glucomannan-gelatin-based capsules, comprising the following steps:

[0035] Step 1, by weight, get 0.025g mannozyme and add 80mL distilled water, stir evenly, then slowly add 10g konjac fine powder in the beaker; Room temperature degradation 10min; Add 10g konjac fine powder in the beaker again, degrade 10min; Add 10g konjac fine powder to the beaker and degrade it for 10 minutes; then add 10 g konjac fine powder to the beaker and degrade it for 10 minutes; adjust the pH to 10, then place it in a constant temperature water bath at 80°C for 20 minutes; cool to room temperature to obtain konjac grape Mannan degradation solution; the content of the degradation solution is 40 / 120=34%;

[0036] Step 2, take konjac glucomannan degradation liquid (the content of konjac glucomannan is 4g), add glycerin, at 70 ℃, stir at 150rpm, then add gelatin 4g, stir at 50rpm, until the The gelatin is completely dissolved to obtain a mixed sol; the added amou...

Embodiment 2

[0039] The amount of gelatin added is 8g, and all the other processes and parameters are identical to those in Example 1.

Embodiment 3

[0041] The amount of konjac glucomannan degradation solution added was (the content of konjac glucomannan was 8g), and the rest of the process and parameters were exactly the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com