Heat treatment method capable of improving natural aging stability of 6000-series aluminum alloy and aluminum alloy plate

A heat treatment method and aluminum alloy sheet technology, which is applied in the field of aluminum alloy heat treatment, can solve the problems of inability to maintain the hardening performance of the baking paint for a long time, short natural aging stability, and inability to maintain formability, etc., and achieve the extension of the retention time of the baking hardening performance. Effect of alleviating stagnation effect at room temperature and reducing hardening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] A heat treatment method for improving the natural aging stability of 6000 series aluminum alloys, comprising the following steps:

[0106] (1) Melting 6016 aluminum alloy, after 560°C-12h homogenization annealing process, hot rolling and cold rolling to 1.2mm plate;

[0107] Among them, the 6016 aluminum alloy is composed of the following components in mass percentage: 0.95% Mg, 0.75% Si, 0.12% Cu, 0.3% Fe, 0.05% Cr, 0.04% Ti, 0.03% Zn, and the balance is Al.

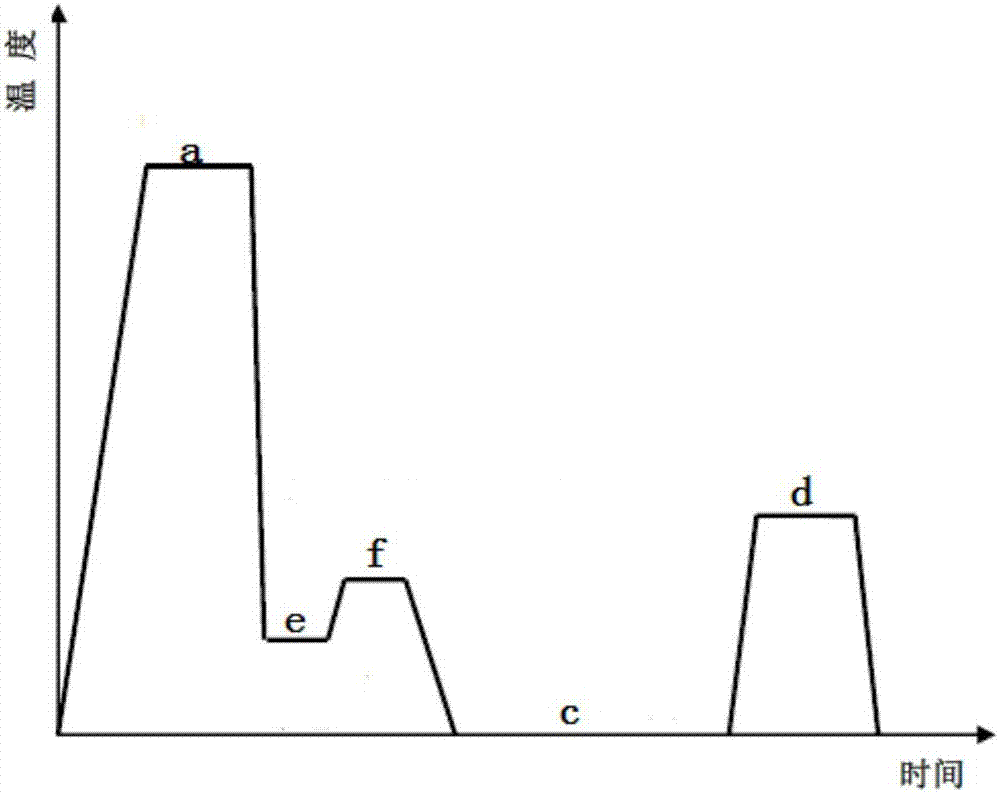

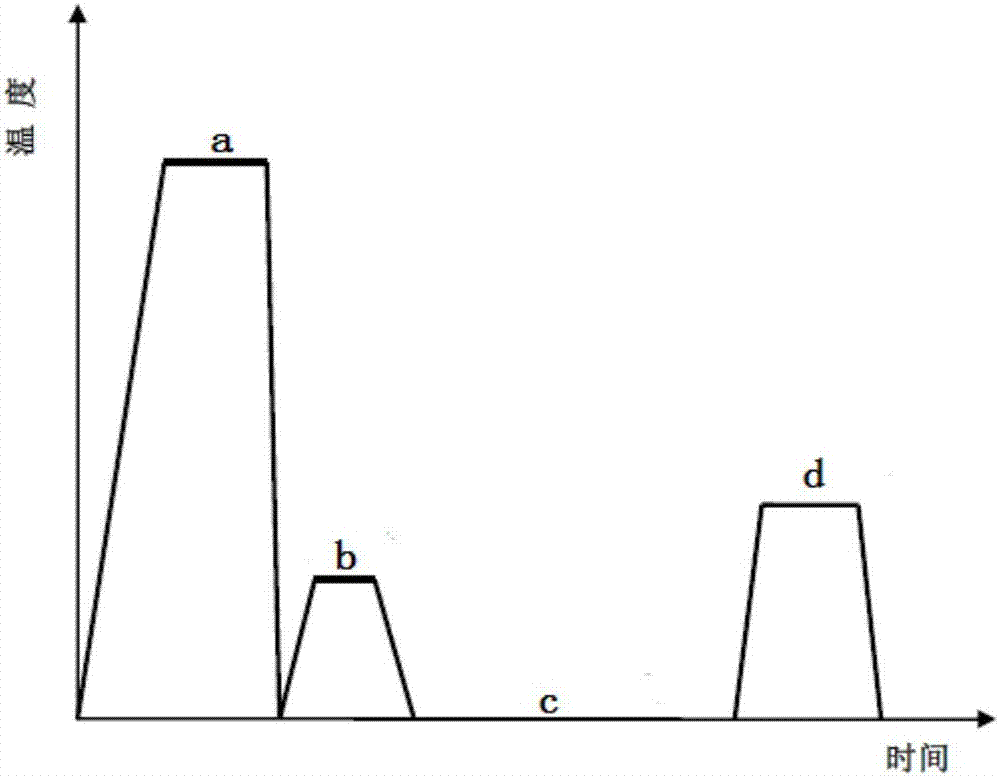

[0108] (2) Heat treat the 6016 aluminum alloy sheet obtained in step (1) in a continuous annealing furnace, first heat it to 550°C at a heating rate of 10°C / s, hold it for 15min, and then quench it to 60°C at a quenching rate of 30°C / s ℃, keep warm for 10min, then rapidly raise the temperature to 120℃ at a heating rate of 30℃ / s, keep warm for 3min, and finally air cool to room temperature;

[0109] (3) After cooling the aluminum alloy sheet in step (2) to room temperature for one week, two weeks, one month, two ...

Embodiment 2

[0116] A heat treatment method for improving the natural aging stability of 6000 series aluminum alloys, comprising the following steps:

[0117] (1) Melting 6016 aluminum alloy, after 520°C-24h homogenization annealing process, hot rolling and cold rolling to 1.2mm plate;

[0118] Among them, the 6016 aluminum alloy is composed of the following components in mass percentage: 0.50% Mg, 1.00% Si, 0.10% Cu, 0.50% Fe, 0.05% Cr, 0.15% Ti, 0.02% Zn, and the balance is Al.

[0119] (2) Heat-treat the 6016 aluminum alloy sheet obtained in step (1) in a continuous annealing furnace, first heat it to 560°C at a heating rate of 10°C / s, keep it for 10min, and then quench it to 40°C at a quenching rate of 35°C / s ℃, keep warm for 15min, then rapidly raise the temperature to 100℃ at a heating rate of 30℃ / s, keep warm for 5min, and finally air cool to room temperature;

[0120] (3) After cooling the aluminum alloy sheet in step (2) to room temperature for one week, two weeks, one month, two...

Embodiment 3

[0125] A heat treatment method for improving the natural aging stability of 6000 series aluminum alloys, comprising the following steps:

[0126] (1) Melting 6016 aluminum alloy, after homogenization annealing process at 540°C-18h, hot rolling and cold rolling to 1.2mm plate;

[0127] Among them, the 6016 aluminum alloy is composed of the following components in mass percentage: Mg 1.20%, Si 0.40%, Cu 1.00%, Cr 0.15%, Ti 0.02%, Zn 0.10%, and the balance is Al.

[0128] (2) Heat treat the 6016 aluminum alloy plate obtained in step (1) in a continuous annealing furnace, first heat it to 580°C at a heating rate of 8°C / s, keep it for 10min, and then quench it to 60°C at a quenching rate of 30°C / s ℃, keep warm for 5min, then rapidly raise the temperature to 110℃ at a heating rate of 20℃ / s, keep warm for 4min, and finally air cool to room temperature;

[0129] (3) After cooling the aluminum alloy sheet in step (2) to room temperature for one week, two weeks, one month, two months, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com