Production method of acid-resistant pipeline steel

A production method and pipeline steel technology, applied in the field of metallurgy, can solve the problems of long production cycle, high cost, uneven structure, etc., and achieve the effects of reducing hardening effect, low production cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

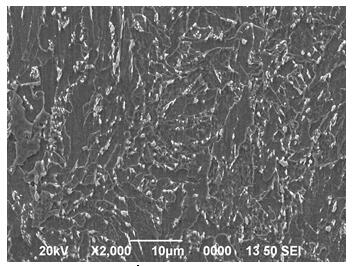

Image

Examples

Embodiment 1

[0019] Example 1: Production of 9.5mmX65MS tempered pipeline steel

[0020] Steel smelting chemical composition content C=0.04%, Si=0.20%, Mn=1.18%, P=0.009%, S=0.0001%, Alt=0.026%, Nb=0.042%, Ti=0.014%, Mo=0.08% , Ni=0.13%, Cu=0.17%, Pcm=0.14%, the balance is Fe and unavoidable impurities.

[0021] (1) Heating: Furnace temperature 1100~1260°C, gas flow rate 4250Nm3 / h~4450 Nm3 / h, air-fuel ratio 1.16, furnace pressure 4Pa, total time in the furnace 286min, heating speed 6min / cm, furnace core temperature 1228°C.

[0022] (2) Rough rolling: the intermediate billet is set to 65mm, and the cumulative reduction rate is 73.1%. Longitudinal rolling is adopted to expand the width. %, 24.3%, 28.9%, and the rolling temperature is controlled at 1100~980°C.

[0023] (3) Finish rolling: the starting rolling temperature is 960°C, the cumulative reduction rate is 85.4%, the single pass reduction rate is 15%~20%, the rolling speed is 4~6m / s, and the final rolling temperature is 820~860°C.

...

Embodiment 1

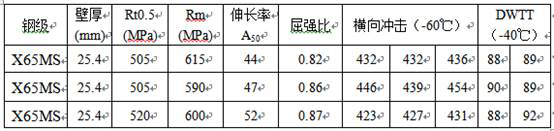

[0026] Example 1 The mechanical properties of 9.5mmX65MS tempered pipeline steel are shown in Table 1.

[0027] Table 1 Mechanical properties of 9.5mmX65MS tempered pipeline steel

[0028]

Embodiment 2

[0029] Example 2: Production of 25.4mmX65MS tempered pipeline steel

[0030] Steel smelting chemical composition content C=0.03%, Si=0.22%, Mn=1.16%, P=0.008%, S=0.0001%, Alt=0.024%, Nb=0.043%, Ti=0.016%, Mo=0.09% , Ni=0.13%, Cu=0.16%, Pcm=0.13%, the balance is Fe and unavoidable impurities.

[0031] (1) Heating: furnace temperature 1100~1260℃, gas flow 4250Nm3 / h~4500 Nm3 / h, air-fuel ratio 1.21, furnace pressure 3.5Pa, total time in the furnace 292min, heating speed 6.2min / cm, furnace core temperature 1216 ℃.

[0032] (2) Rough rolling: the intermediate billet is set to 80mm, and the cumulative reduction rate is 69.2%. Longitudinal rolling is adopted to expand the width. %, 23.6%, 26.8%, and the rolling temperature is controlled at 1100~980°C.

[0033] (3) Finish rolling: the starting rolling temperature is 920°C, the cumulative reduction rate is 68.25%, the single pass reduction rate is 13%~20%, the rolling speed is 3.5~5.5m / s, and the final rolling temperature is 810~850°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com