Method for manufacturing vein-proof sand core

A manufacturing method and veining technology, applied in the direction of manufacturing tools, cores, casting molding equipment, etc., can solve the problems of veins on the inner surface of casting chambers, poor plasticity and yield, micro cracks on the surface of sand cores, etc., and achieve skeleton density The effect of improving, improving stability, and improving finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

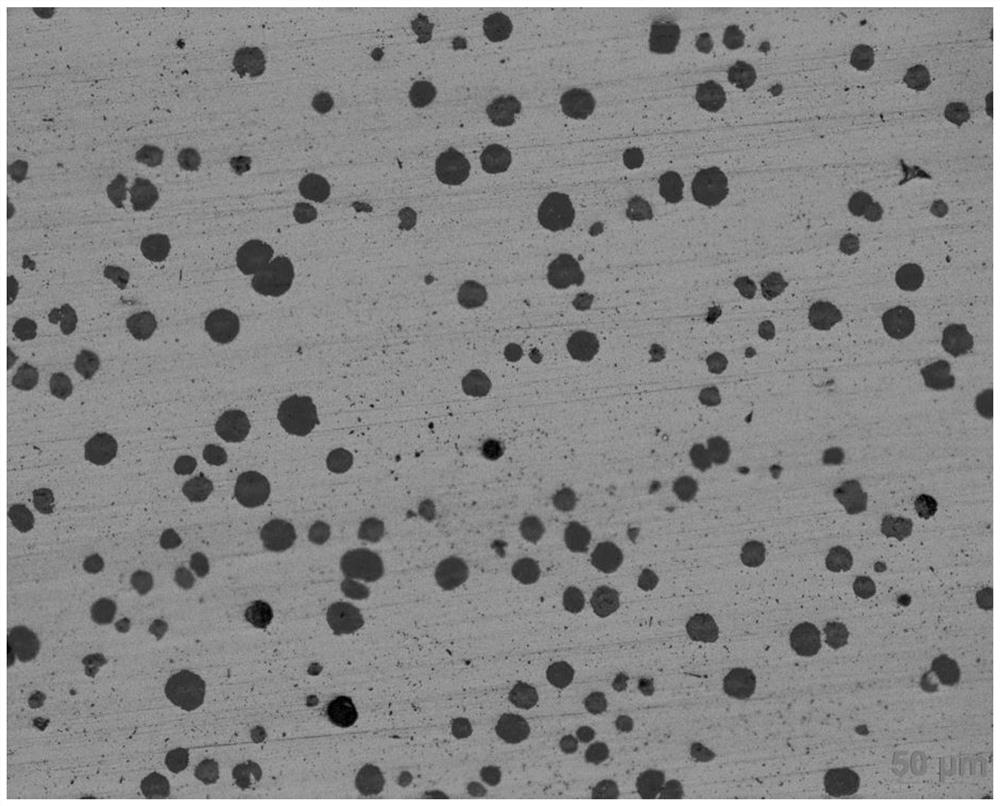

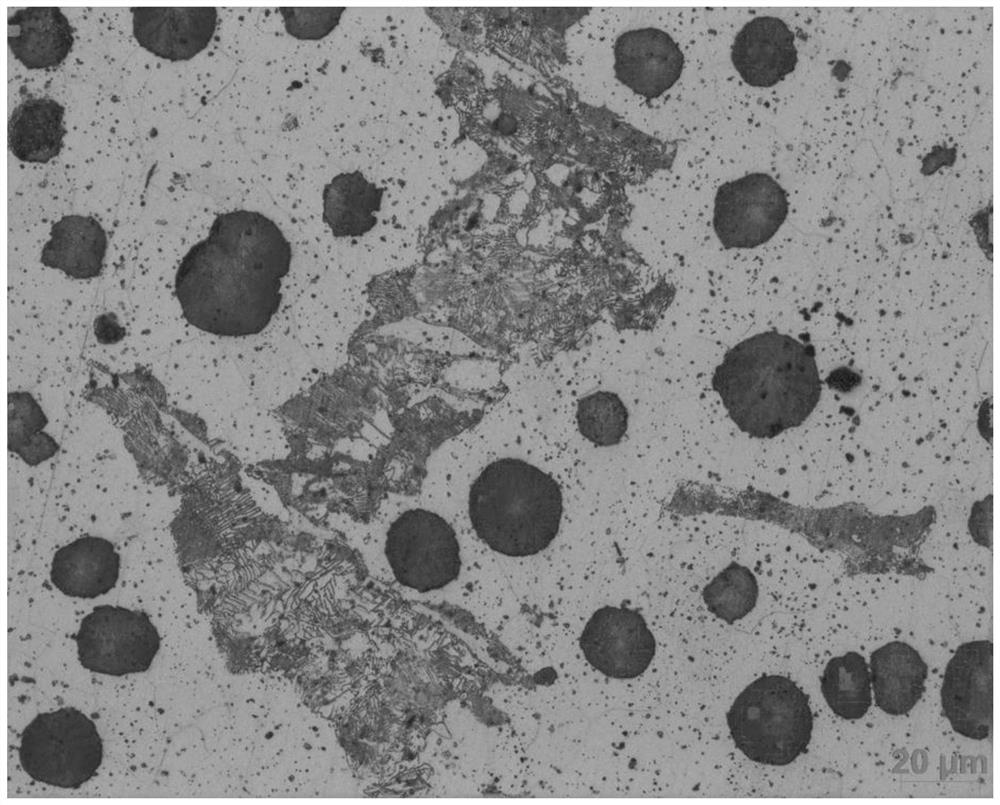

[0036] The raw materials used in embodiment 1 of the manufacture method of the anti-veining sand core of the present invention, calculated according to weight percentage, include quartz sand 94, phenolic resin 2.2, coating 1, anti-veining agent 2 and auxiliary material 0.8 (the auxiliary material is carbon powder or bentonite). The anti-veining agent is divided into two groups, calculated according to weight percentage, the anti-veining agent of the first group is 80, and the anti-veining agent of the second group is 20.

[0037] The first group of anti-veining agent is different from the second group of anti-veining agent; wherein, graphite powder, ferrosilicon powder and pearlite refiner are also added in the second group of anti-veining agent, specifically: the first group of anti-veining agent A group of anti-veining agent components, calcu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com