Ceramic composite material forming method and ceramic composite material

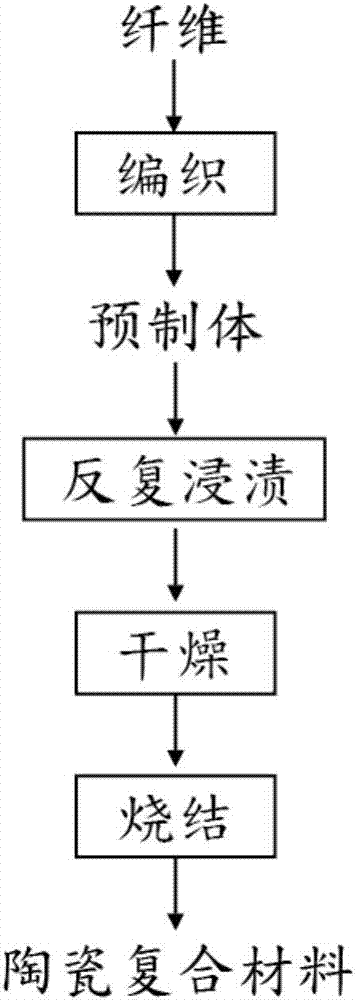

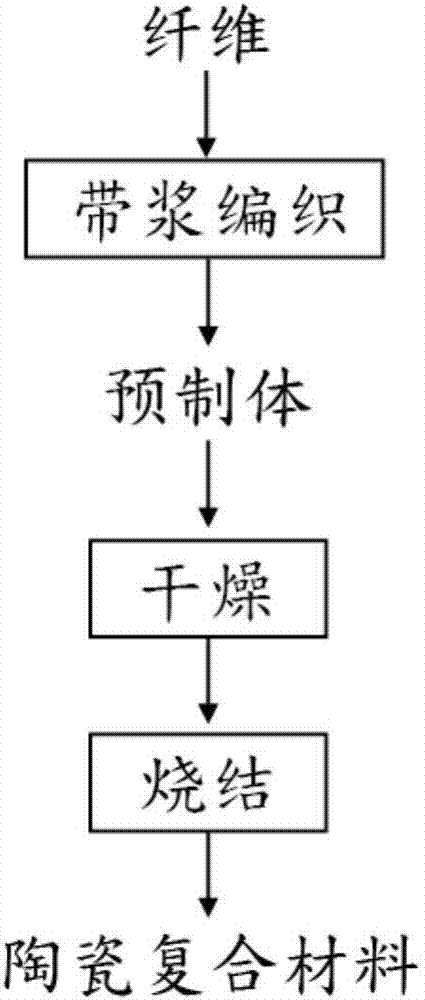

A technology of ceramic composite material and molding method, applied in ceramic molding machines, manufacturing tools and other directions, can solve the problems of insufficient density of ceramic composite materials, increased production cost, prolonged production cycle, etc., to improve the complex molding process and save work costs. , the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] A method for forming a ceramic composite material, comprising the steps of:

[0075] (a) impregnating the fibers in the slurry;

[0076] Specifically, the preparation method of the slurry is mainly prepared according to the following steps:

[0077] Quartz powder (SiO 2 content is 99.9%), according to the weight ratio of 1:1:2:2:3:1, add to the high-purity silica sol with a solid content of 23%, according to the principle that the solid content of the slurry is 76% Add an appropriate amount of quartz powder, then add lactic acid according to 1% of the weight of the slurry, mix the above materials, and ball mill for 3.5 hours at a speed of 450r / min in a ball mill tank to obtain a slurry;

[0078] Put the slurry in an impregnation tank with ultrasonic dispersion function, place the fiber to be woven into the slurry for impregnation, turn on the ultrasonic dispersion switch, and perform ultrasonic dispersion on the slurry and fiber at the same time, so that the inside of...

Embodiment 2

[0086] A method for forming a ceramic composite material, comprising the steps of:

[0087] (a) impregnating the fibers in the slurry;

[0088] Specifically, the preparation method of the slurry is mainly prepared according to the following steps:

[0089] Silicon carbide powder with a particle size of 200 mesh, 300 mesh, 500 mesh, 700 mesh, 900 mesh, 1100 mesh and 1200 mesh respectively, according to the weight ratio of 1:1:1:2:2:3:1, add To the precursor solution with a solid content of 20%, add an appropriate amount of silicon carbide powder according to the principle that the solid content of the slurry is 70%, and then add lactic acid according to 1% of the weight of the slurry. After mixing the above materials, put them in a ball mill tank Grind for 3h at a speed of 500r / min to obtain a slurry;

[0090] Put the slurry in an impregnation tank with ultrasonic dispersion function, place the fiber to be woven into the slurry for impregnation, turn on the ultrasonic dispers...

Embodiment 3

[0098] A method for forming a ceramic composite material, comprising the steps of:

[0099] (a) impregnating the fibers in the slurry;

[0100] Specifically, the preparation method of the slurry is mainly prepared according to the following steps:

[0101] Quartz powder (SiO 2 content is 99.9%), according to the weight ratio of 1:1:2:2:3:1, add to the high-purity silica sol with a solid content of 23%, according to the principle that the solid content of the slurry is 71% Add an appropriate amount of quartz powder, and then add lactic acid according to 1% of the weight of the slurry. After mixing the above materials, ball mill at a speed of 450 r / min for 3.5 hours in a ball mill jar to obtain a slurry.

[0102] Put the slurry in an impregnating tank with ultrasonic dispersion function, place the fiber to be woven into the slurry to impregnate, turn on the ultrasonic dispersion switch, so that the inside of the fiber is fully infiltrated with the slurry.

[0103] (b) Mold pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com