Pouring device for aerated bricks

A kind of technology of aerated bricks and pouring tanks, which is applied in the direction of supply device, cement mixing device, clay preparation device, etc., which can solve the problems of small addition of aerated brick auxiliary materials, affecting the quality of aerated bricks, uneven mixing, etc., and achieve high vibration efficiency , Improve production efficiency, improve the effect of reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

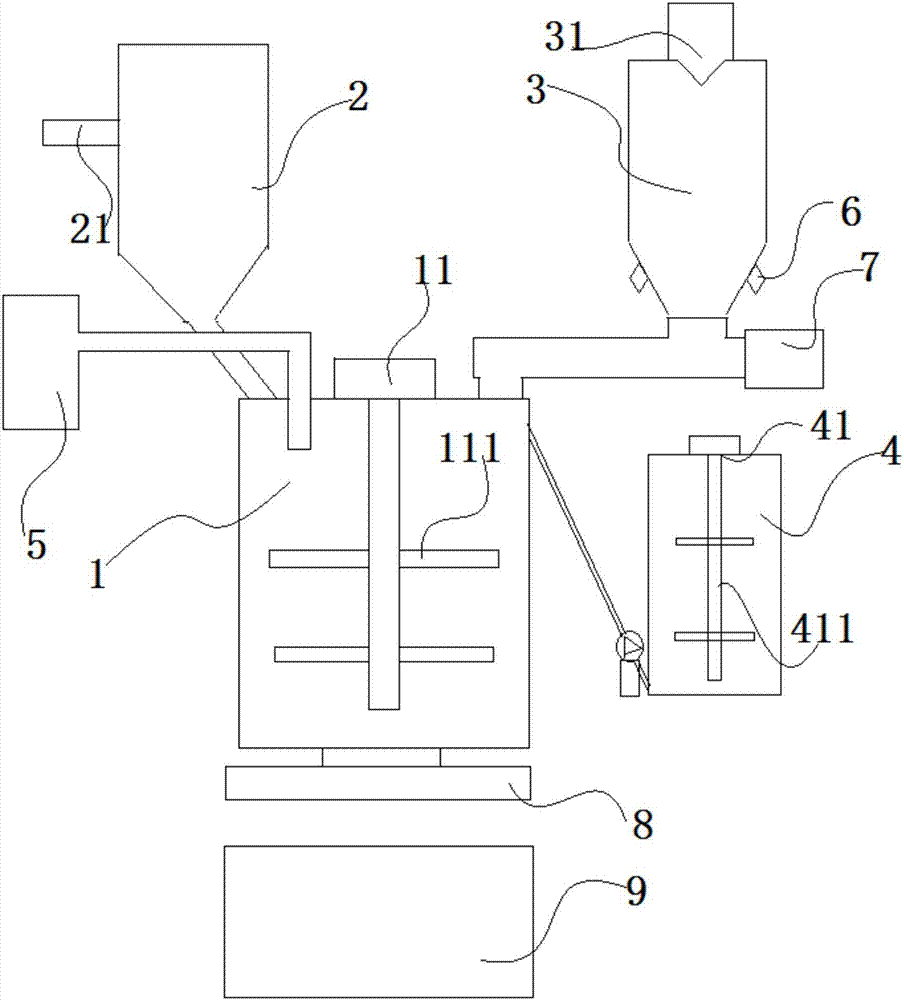

[0037] The aerated brick pouring device of the present embodiment, such as figure 1 As shown, it includes a pouring tank 1, a slurry tank 2 and a powder tank 3, and also includes an auxiliary material tank 4, wherein: the slurry tank 2 communicates with the pouring tank 1 through a slurry pipe, and the powder tank 3 is provided through its bottom The conveying mechanism 7 communicates with the pouring tank 1, and the auxiliary material tank 4 sends the auxiliary material into the pouring tank 1 through the auxiliary material pipe and the auxiliary material pump;

[0038] In the aerated brick pouring device of this embodiment, the slurry is passed into the slurry tank 2 through the slurry pipe 21, and the powder is lifted to the powder tank 3 by the powder hoist 31. By adding the auxiliary material tank 4, the concentration will be added The auxiliary materials with small amount and many varieties are mixed evenly through the auxiliary material tank 4 and then added into the po...

Embodiment 2

[0040] The basic structure of the aerated brick pouring device of this embodiment is the same as that of Embodiment 1. The differences and improvements are: the pouring tank 1 and the auxiliary material tank 4 are respectively equipped with a mixer A11 and a mixer B41 to improve the uniformity of mixing and ensure the production of gas. Stable brick quality; the conveying mechanism 7 is a horizontal conveying auger or a scraper, with high conveying efficiency and low cost. The stirring rods of the mixer A11 and the mixer B41 are the stirring rod A111 and the stirring rod B411 in the shape of "string" respectively, which have high stirring efficiency and no dead angle. The top of the pouring tank 1 is also externally connected with a heating mechanism 5 to improve the reaction speed and stirring efficiency.

Embodiment 3

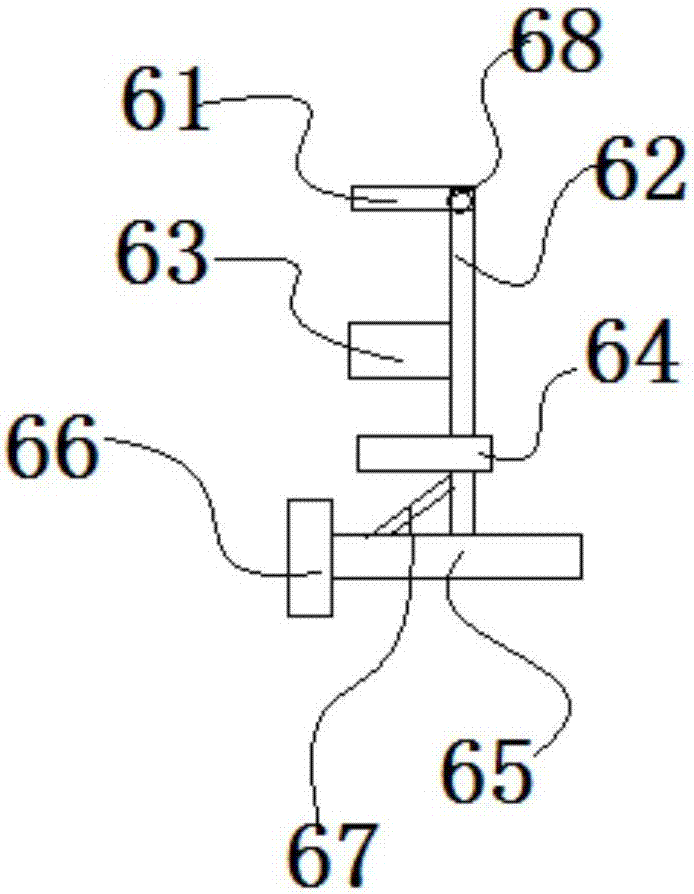

[0042] The basic structure of the aerated brick pouring device of this embodiment is the same as that of Embodiment 2. The difference and improvement are that the heating mechanism 5 is heated by steam, communicates with the pouring tank 1 through a steam pipe, has high heating efficiency, and cooperates with the agitator. Further improve the reaction speed of various ingredients. The bottom of the powder tank 3 is in the shape of a tapered tube to close the mouth, and there is no dead angle for blanking. The outer wall of the cone tube is fixed with a vibrating mechanism 6 to prevent incomplete blanking of the powder. The vibrating mechanism 6 is evenly and symmetrically distributed along the outer wall of the conical cylinder to improve the vibrating efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com