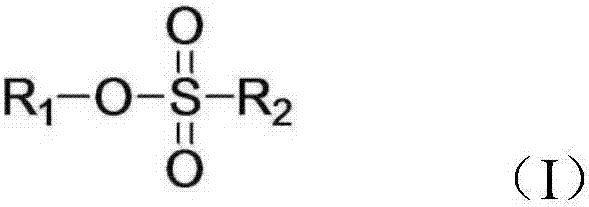

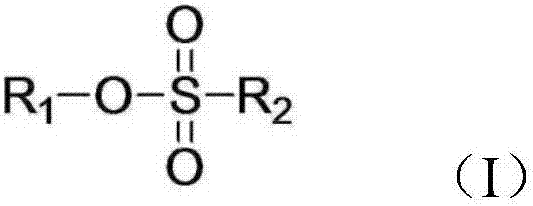

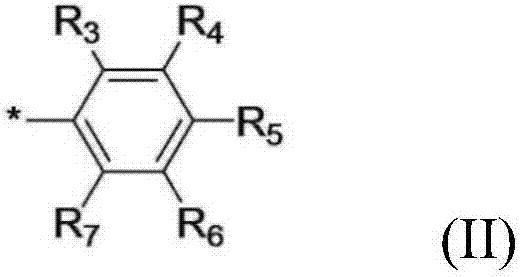

Colored Photosensitive Resin Composition and Color Filter Comprising the Same

A technology of photosensitive resin and composition, which is applied in the direction of photosensitive materials, instruments, optics, etc. used in photomechanical equipment, can solve problems such as insufficient curing degree, and achieve good adhesion and chemical resistance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0176] Preparation Example 1: Preparation of Alkali-soluble Resin

[0177] Add 200 parts by weight of propylene glycol monomethyl ether acetate, 45 parts by weight of propylene glycol monomethyl ether, 2 Azobisisobutyronitrile (AIBN), 15 parts by weight of acrylic acid, 70 parts by weight of benzyl methacrylate, 15 parts by weight of styrene and 3 parts by weight of n-dodecanethiol, then nitrogen replacement . After that, the temperature of the reaction solution was raised to 110° C. with stirring, and the reaction was continued for 8 hours to obtain an alkali-soluble resin. It was confirmed that the obtained alkali-soluble resin had a weight average molecular weight (Mw) of about 16000 and an acid value of 100.4 mg KOH / g by GPC measurement.

Embodiment 1 to 6 and comparative example 1 to 6

[0178] Examples 1 to 6 and Comparative Examples 1 to 6: Preparation of Colored Photosensitive Resin Compositions

[0179] A colored photosensitive resin composition was prepared by mixing the ingredients in the ratios listed in Table 1 below (unit: parts by weight).

[0180] 【Table 1】

[0181]

[0182] 1) LTN-207 (manufactured by Loum Hitech)

[0183]

[0184] 2) LTN-201 (manufactured by Loum Hitech)

[0185]

[0186] 3) LTN-107 (manufactured by Loum Hitech)

[0187]

[0188] 4) Pyridinium p-toluenesulfonate (manufactured by Sigma-Aldrich)

[0189]

[0190] 5) C.I Pigment Blue 15:6

[0191] 6) the resin obtained in Preparation Example 1

[0192] 7) Dipentaerythritol hexaacrylate (manufactured by Nippon Kayaku Co., Ltd.)

[0193] 8) 2-Benzyl-2-dimethylamino-1-(4-morpholinophenyl)butan-1-one (manufactured by Ciba Specialty Chemicals).

[0194] 9) Propylene Glycol Monomethyl Ether Acetate

experiment example 1

[0195] Experimental Example 1: Evaluation of Solvent Resistance and Adhesiveness

[0196] Color filters were prepared using the colored photosensitive resin compositions prepared in Examples and Comparative Examples.

[0197]Specifically, each colored photosensitive resin composition was coated on a glass substrate by spin coating, and the glass substrate was placed on a heating plate and maintained at a temperature of 100° C. for 3 minutes to form a thin film on the glass substrate. Subsequently, a test photomask (with a pattern exhibiting a stepped transmittance in the range of 1% to 100% and a line / space pattern of 1 μm to 50 μm) was placed on the film, and Use a 1KW high pressure mercury lamp at 100mJ / cm with an interval of 100μm 2 Under UV irradiation without any special filter, the mercury lamp includes all of the g-line, h-line and i-line. The ultraviolet irradiated film was immersed in an aqueous KOH solution (pH 10.5) used as a developing solution for 2 minutes. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com