A kind of rolling method of 22crmoh gear steel

A gear steel, rolling deformation technology, applied in the field of gear steel, can solve problems such as not very ideal, increasing the difficulty of production, strong demand for gear steel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

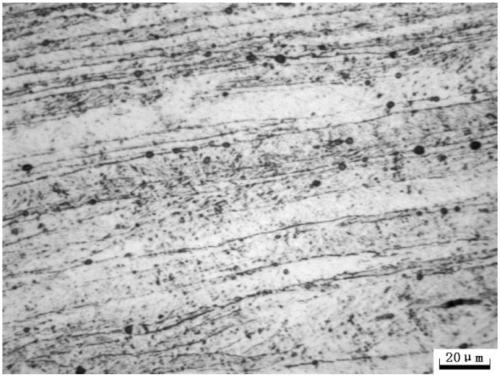

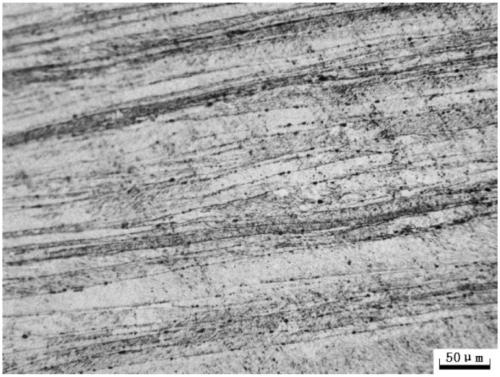

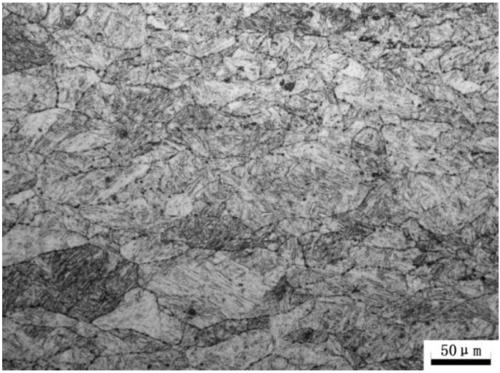

Image

Examples

Embodiment 1

[0039] A rolling method of 22CrMoH gear steel, comprising the following steps:

[0040] (1) Put the continuous casting slab containing the chemical composition and mass percentage shown in Example 1 in Table 1 below 850°C into the heating furnace, and heat it to the soaking temperature after 4 hours. The temperature in the soaking section is 1170-1220°C, After heat preservation for 4 hours, it leaves the heating furnace, and the heated continuous casting slab is dephosphorized by high-pressure water to remove iron oxide scale;

[0041] (2) The round steel billet after dephosphorization is subjected to billeting to obtain a blooming billet, the billeting temperature is 1000-1050°C, and the deformation in a single pass of billeting is greater than 20%;

[0042] (3) The blooming slab is rolled in a continuous rolling mill, and the continuous rolling temperature is 850-950°C, wherein the rolling deformation at 870-920°C is greater than 30%, and the final rolling temperature is 850...

Embodiment 2

[0048] A rolling method of 22CrMoH gear steel, comprising the following steps:

[0049] (1) Put the continuous casting slab containing the chemical composition and mass percentage shown in Example 2 in Table 1 below 850°C into the heating furnace, and heat it to the soaking temperature after 4 hours. The temperature in the soaking section is 1150-1200°C, After heat preservation for 4 hours, it leaves the heating furnace, and the heated round steel billet is dephosphorized by high-pressure water to remove iron oxide scale;

[0050] (2) The continuous casting slab after dephosphorization is carried out to obtain the blooming slab, the temperature of the slab is 1000-1050 ℃, and the deformation of the single pass of the slab is greater than 20%;

[0051] (3) The blooming slab is rolled in a continuous rolling mill, and the continuous rolling temperature is 830-930°C, wherein the rolling deformation at 860-900°C is greater than 30%, and the final rolling temperature is 830°C;

[...

Embodiment 3

[0057] A rolling method of 22CrMoH gear steel, comprising the following steps:

[0058] (1) Put the continuous casting slab containing the chemical composition and mass percentage shown in Example 3 in Table 1 below 850°C into the heating furnace, and heat it to the soaking temperature after 4 hours. The temperature in the soaking section is 1140-1180°C, After heat preservation for 4 hours, it leaves the heating furnace, and the heated round steel billet is dephosphorized by high-pressure water to remove iron oxide scale;

[0059] (2) The continuous casting slab after dephosphorization is carried out to obtain the blooming slab, the temperature of the slab is 1000-1050 ℃, and the deformation of the single pass of the slab is greater than 20%;

[0060] (3) The blooming slab is rolled in a continuous rolling mill, and the continuous rolling temperature is 800-900°C, wherein the rolling deformation at 870-900°C is greater than 30%, and the final rolling temperature is 800°C;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com