Method for preparing copper titanate calcium-based ceramic with core-shell structure

A technology of calcium copper titanate and shell structure is applied in the field of preparation of calcium copper titanate-based ceramics, which can solve the problems of low-frequency dielectric constant reduction of CCTO ceramics, and achieve the advantages of reducing dielectric loss, increasing insulation and improving oxidation degree. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

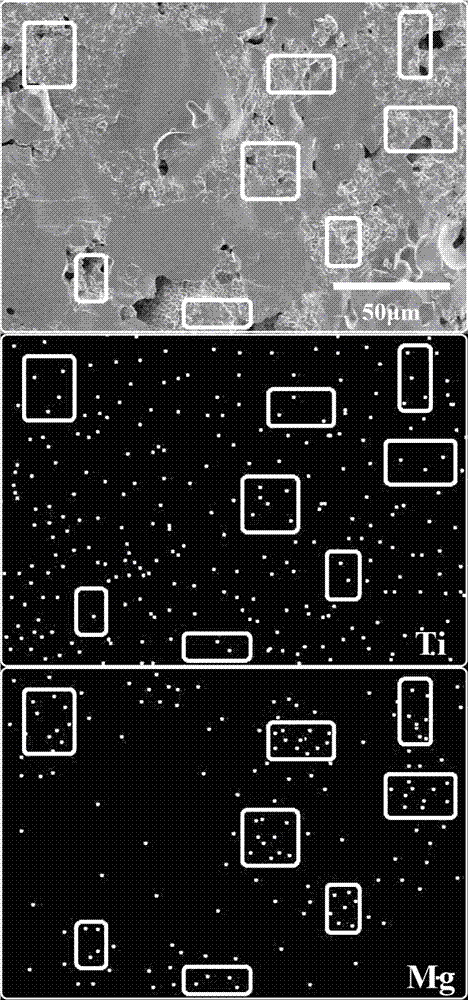

[0011] To analyze pure calcium nitrate (Ca(NO 3 ) 2 • 4H 2 O, 99%), copper nitrate (Cu(NO 3 ) 2 •3H 2 O, 99%) and tetrabutyl titanate ([CH 3 (CH 2 ) 3 O] 4 Ti, 99%) as the initial raw material, adding citric acid (C 6 h 8 o 7 , 99%), the CCTO precursor powder was prepared by the sol-gel method, first according to the CaCu 3 Ti 4 o 12 The stoichiometric ratio of various raw materials is accurately weighed, then dissolved in ethanol and mixed evenly, and the pH of the solution is only adjusted to 2~3 with nitric acid. After the solution was stirred by magnetic force, it was placed in a constant temperature of 80°C and incubated for 6 hours to make the solution form a colloid, and then kept in a constant temperature of 100°C for 2 hours to become a xerogel. The xerogel was calcined in the atmosphere at 750°C for 2 hours to obtain CCTO powder. Next follow CCTO / xMgTiO 3 (x=0, 0.5, 1 and 2) stoichiometric ratio Accurately weigh CCTO powder, magnesium nitrate (Mg(NO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com