An adhesive composition, an adhesive method using the adhesive composition and a method for producing the layered product

A composition and adhesive technology, applied in the direction of bonding methods, non-polymer organic compound adhesives, non-polymer adhesive additives, etc., can solve air bubbles involved, equipment fouling, and difficult to obtain bonding Solve problems such as the uniformity of the thickness of the agent layer, and achieve the effect of excellent concave-convex followability and high-efficiency bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0118] The preparation method of the adhesive composition of the present invention is not particularly limited, for example, the polyalkylene oxide addition polyfunctional epoxy compound (a) represented by the above general formula (A), polyfunctional (methyl) Acrylate monomer (b), photoacid generator (c) and additives are prepared by conventional methods such as stirring until uniform. It should be noted that, in order to prevent the decomposition of the photoacid generator (c), it is preferably prepared under light-shielding conditions.

[0119] In addition, in order to prevent the decomposition of the photoacid generator (c), the adhesive composition of the present invention after preparation is also preferably stored in a light-shielded manner.

[0120]

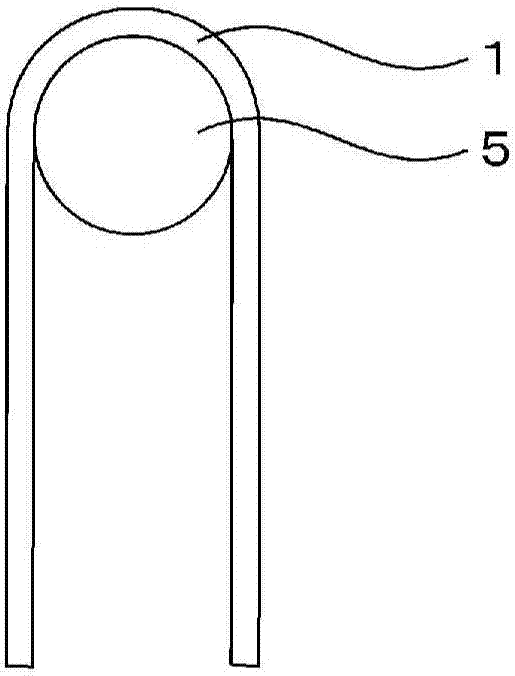

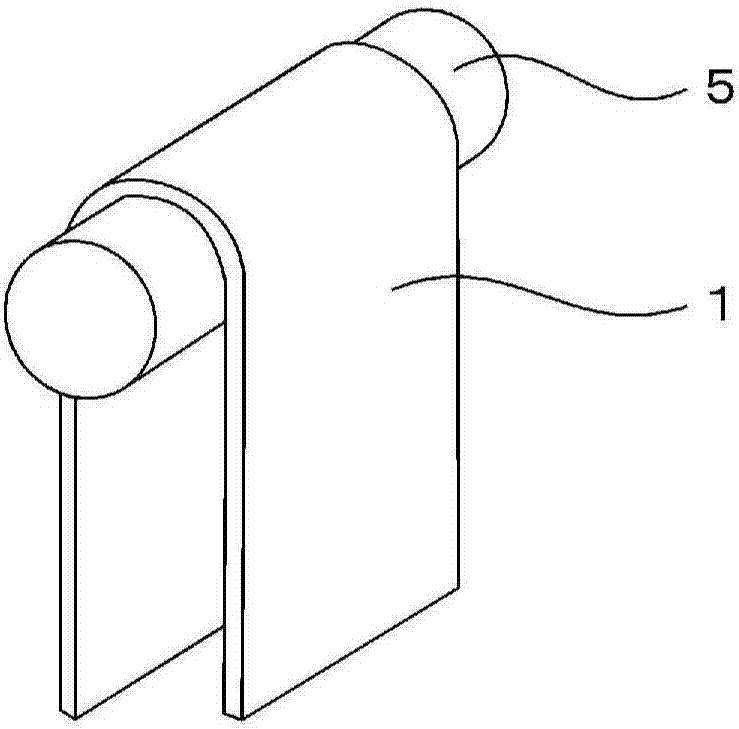

[0121] The bonding method of the adherends A and B using the adhesive composition of the present invention includes the following steps A and B in this order.

[0122] Step A: a step of applying the adhesive compositio...

Embodiment 1

[0150] According to the mass ratio of Table 1, RikaresinBEO-60E (trade name, manufactured by Nippon Chemical Co., Ltd.) as a polyalkylene oxide addition polyfunctional epoxy compound (a), as a polyfunctional (meth)acrylate monomer ( b) A-NOD-N (trade name, manufactured by Shin-Nakamura Chemical Industry Co., Ltd.), CPI-200K (trade name, manufactured by San-Apro Corporation) as a photoacid generator (c), were stirred until uniform, and viscous Adhesive composition.

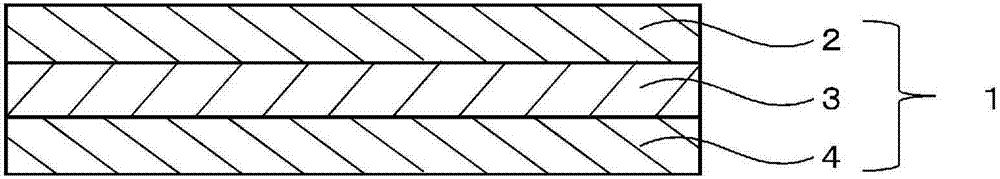

[0151] The prepared adhesive composition was applied to a PET film with a thickness of 25 μm (trade name “G2”, manufactured by Teijin DuPont Co., Ltd.) with a thickness of 20 μm, and an ultraviolet irradiation device (trade name: US5-0151, EYEGRAPHICS manufactured by the company), at 50mW / cm 2 Irradiate for 60 seconds (irradiation dose: 2000mJ / cm 2 ) ultraviolet light. Furthermore, 1 hour after the end of the ultraviolet irradiation, a PET film (trade name "G2", manufactured by Teijin DuPont Co., Ltd.) with a th...

Embodiment 2~10、 comparative example 1~3

[0153]In Example 1, except that the components of the adhesive composition were replaced with the types and mass mixing ratios described in Table 1 below, Examples 2 to 10 and Comparative Example were prepared in the same manner as in Example 1. 1 to 3 adhesive compositions. Except for using the obtained adhesive composition, it was obtained in the same manner as in Example 1. figure 1 The bonded film (1) and the film for the test of the composition described in .

[0154] Here, all the adhesive compositions prepared in Examples 1 to 10 were liquid at 23°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com