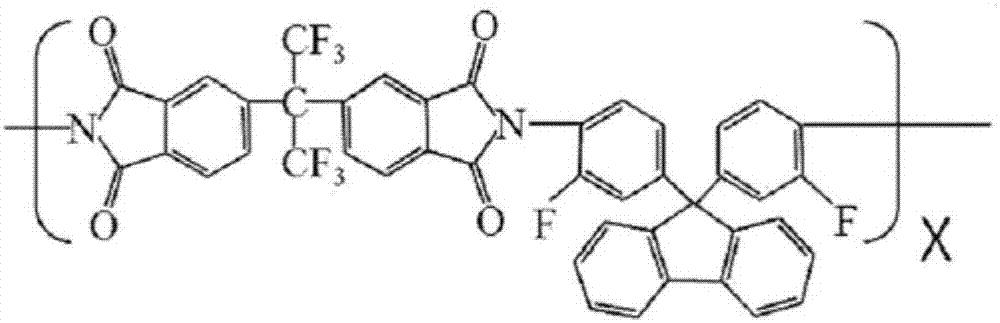

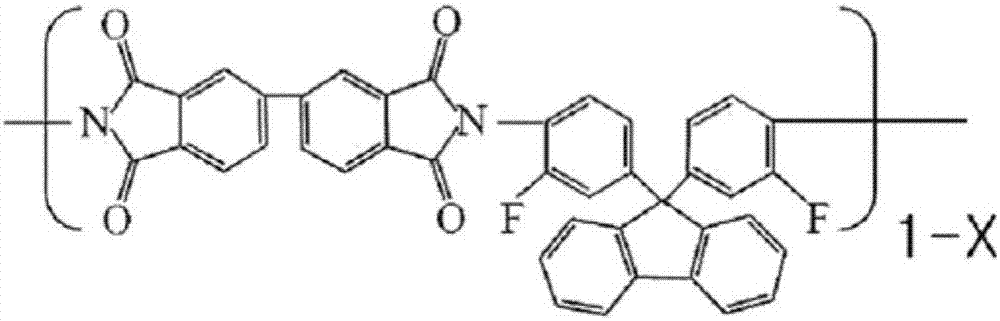

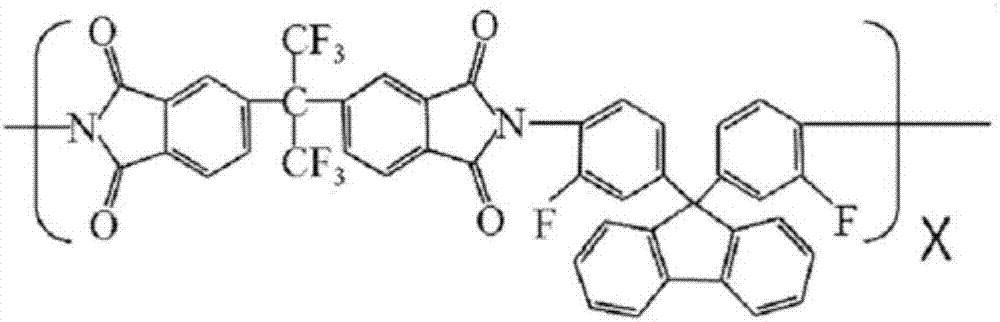

Polyamic acid, polyimide resin and polyimide film

A polyimide film and polyimide resin technology, applied in the field of polyimide film, can solve the problems of insufficient mechanical properties, yellowness and visible light transmittance, and achieve high optical isotropy and excellent Effects of mechanical properties and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A 500mL reactor equipped with stirrer, nitrogen injection device, dropping funnel, temperature controller and condenser was purged with nitrogen, while 384.316g of dimethylacetamide (DMAc) was placed in the reactor, followed by 49.972 g (0.13 mol) of FFDA was dissolved therein. Then, 15.299 g (0.052 mol) of BPDA was added, the reaction was carried out for 5 hours, and 34.652 g (0.078 mol) of 6FDA was added. The resulting solution was kept at room temperature and reacted for 18 hours, thereby obtaining a solid content of 20% by weight, a viscosity (viscosity value using a Brookfield viscometer (RVDV-II+P), at 25° C., using a #6 or #7 spindle , measured twice at 50 rpm, and then averaged) is a polyamic acid solution of 150 poise. After the reaction is terminated, the obtained solution is coated on a stainless steel plate so that the thickness is 10 to 20 μm, dried with hot air at 80°C for 20 minutes, 120°C for 20 minutes, and 300°C for 10 minutes, slowly cooled and separ...

Embodiment 2

[0049] A 500mL reactor equipped with stirrer, nitrogen injection device, dropping funnel, temperature controller and condenser was purged with nitrogen, while 407.493g of dimethylacetamide (DMAc) was placed in the reactor, followed by 49.972g g (0.13 mol) of FFDA was dissolved therein. Then, 11.475 g (0.039 mol) of BPDA was added, the reaction was carried out for 5 hours, and 40.427 g (0.091 mol) of 6FDA was added. The resulting solution was kept at room temperature and reacted for 18 hours to obtain a polyamic acid solution having a solid content of 20% by weight and a viscosity of 127 poise. Subsequent steps were performed in the same manner as in Example 1, thereby producing a polyimide film having a thickness of 10 square.

Embodiment 3

[0051] A 500mL reactor equipped with stirrer, nitrogen injection device, dropping funnel, temperature controller and condenser was purged with nitrogen, while 384.349g of dimethylacetamide (DMAc) was placed in the reactor, followed by 46.128 g (0.12 mol) of FFDA was dissolved therein. Then, 7.061 g (0.024 mol) of BPDA was added, the reaction was carried out for 5 hours, and 42.648 g (0.096 mol) of 6FDA was added. The resulting solution was kept at room temperature and reacted for 18 hours to obtain a polyamic acid solution having a solid content of 20% by weight and a viscosity of 112 poise. Subsequent steps were performed in the same manner as in Example 1, thereby producing a polyimide film having a thickness of 12 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yellowness index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com