Propylene copolymer microcellular foam materials and preparation method thereof

A technology of microcellular foaming material and propylene copolymer, which is applied in the field of propylene copolymer microcellular foaming material and its preparation, can solve the problems of high cost, high price and high equipment requirements, and achieves low cost, light weight, high melting point and high melting point. The effect of high body strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

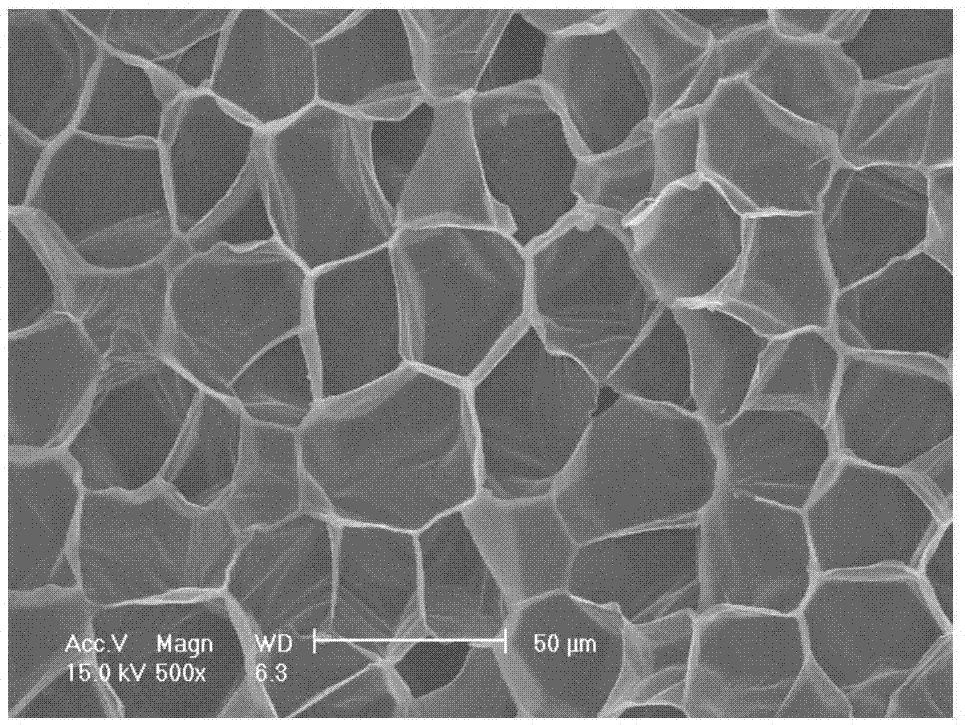

[0031] Ultra-light propylene copolymer foam material

[0032] 1. Formula: 100 parts of propylene copolymer, of which, propylene-ethylene-1-butene terpolymer (the molar content of propylene in the copolymer is 64%, the molar content of ethylene in the copolymer is 12%, 1-butene The molar content of alkene in the copolymer is 24%).

[0033] 2. Process:

[0034]1).Put the propylene-ethylene-1-butene terpolymer powder into the twin-screw extruder to extrude and pelletize. Propylene-ethylene-1-butene terpolymer particles were obtained.

[0035] 2). Put the particles obtained in the above step 1 into a high-pressure reactor. The temperature of the reactor is 140°C, and carbon dioxide gas is introduced at a pressure of 16Mpa. When the carbon dioxide is saturated in the polymer particles for 2 hours, the pressure is released to obtain a foam material, and then put this primary foaming material into another high-pressure reaction kettle, the temperature of the reaction kettle is 145...

Embodiment 2

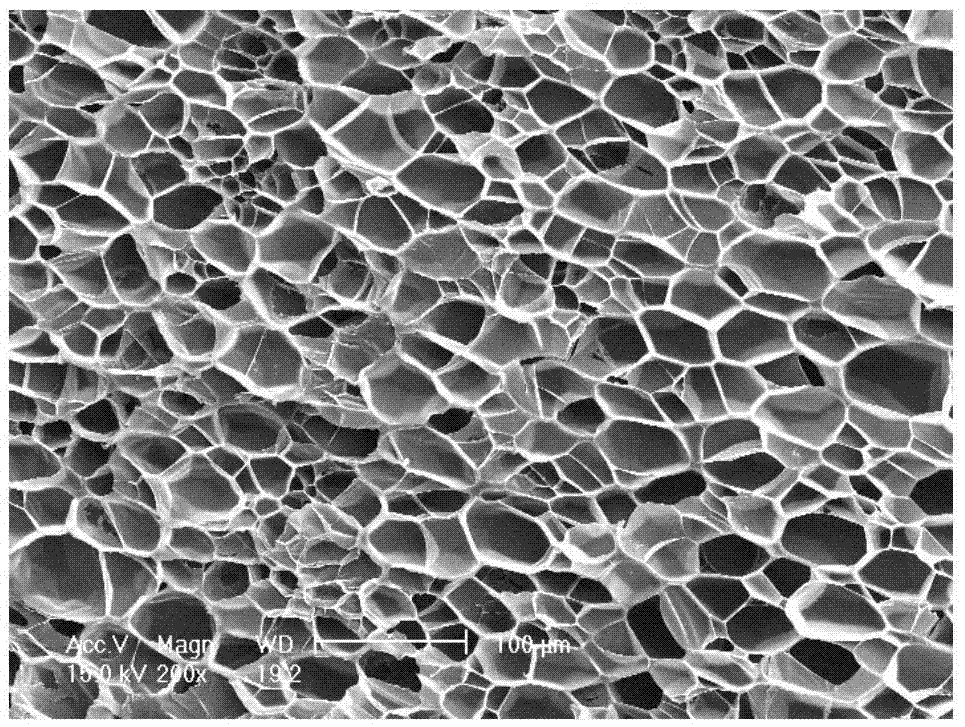

[0040] Antistatic Propylene Copolymer Foam

[0041] 1. Formulation:

[0042] 100 parts of propylene copolymer, 5 parts of CPE as a toughening agent, 1.5 parts of graphene as a filler, 5 parts of polyethylene oxide as an antistatic agent, and 2 parts of a silane coupling agent as a coupling agent.

[0043] Wherein, the propylene copolymer is a propylene-1-butene copolymer (the molar content of 1-butene in the copolymer is 19%).

[0044] 2. Process:

[0045] 1). Weigh the propylene-1-butene copolymer powder, toughening agent, filler, antistatic agent and coupling agent in proportion, add it to the high-speed mixer according to the proportion and mix it for 20 minutes, and then put it into the barrel at a temperature of Extruded by twin-screw extruder at 160℃~210℃, water cooled, pelletized and dried.

[0046] 2) Pass the pellets obtained above through an injection molding machine to obtain a plate by injection molding. Wherein the injection molding machine temperature is betw...

Embodiment 3

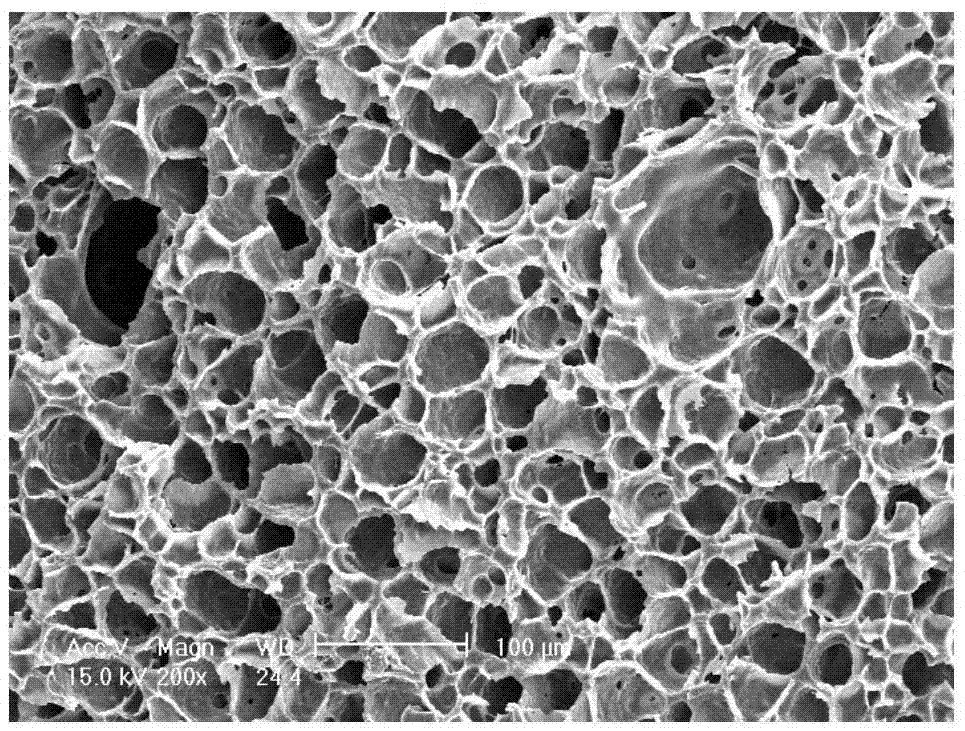

[0051] Flame Retardant Propylene Copolymer Foaming Material

[0052] 1. Formulation:

[0053] 100 parts of propylene copolymer, 5 parts of EPDM as toughening agent, 10 parts of calcium carbonate as filler, 30 parts of magnesium hydroxide as flame retardant, 20 parts of aluminum hydroxide, 15 parts of intumescent flame retardant DTPB, and coupling agent as 3 parts of silane coupling agent.

[0054] Wherein, the propylene copolymer is a propylene-1-pentene copolymer (the molar content of 1-pentene in the copolymer is 13%).

[0055] 2. Process:

[0056] 1). Weigh the propylene-1-pentene copolymer powder, toughening agent EPDM, filler, flame retardant, and coupling agent, add them into the high-speed mixer according to the proportion and mix them for 20 minutes, and then put them into the barrel at a temperature of 160 Extrude twice with twin-screw extruder at ℃~210℃, then dry and set aside.

[0057] 2) Pass the pellets obtained above through an injection molding machine to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com