Soil source heat exchange system applied to solar cell panel

A solar panel and heat exchange system technology, which is applied in the field of heat exchange systems, can solve problems such as reduced work efficiency, reduced open circuit voltage, and shortened lifespan, achieving the effects of reduced workload, fast heat conduction, and guaranteed service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

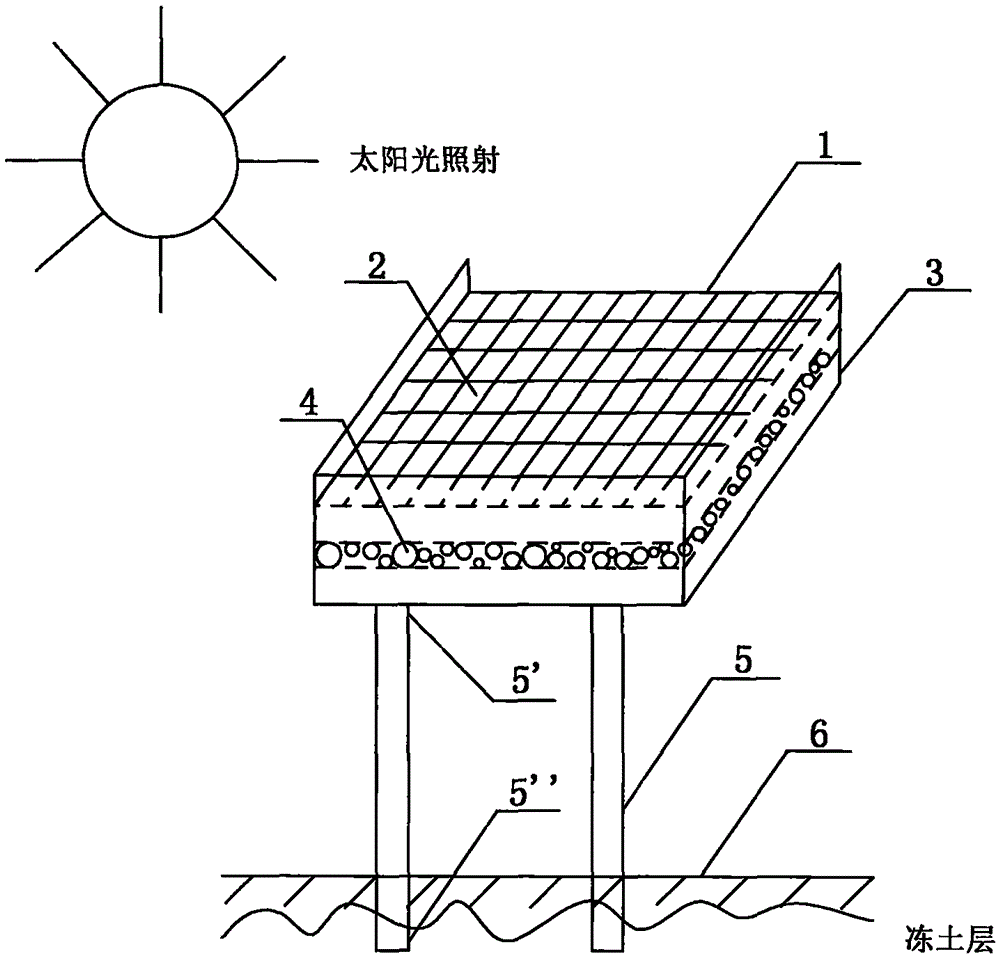

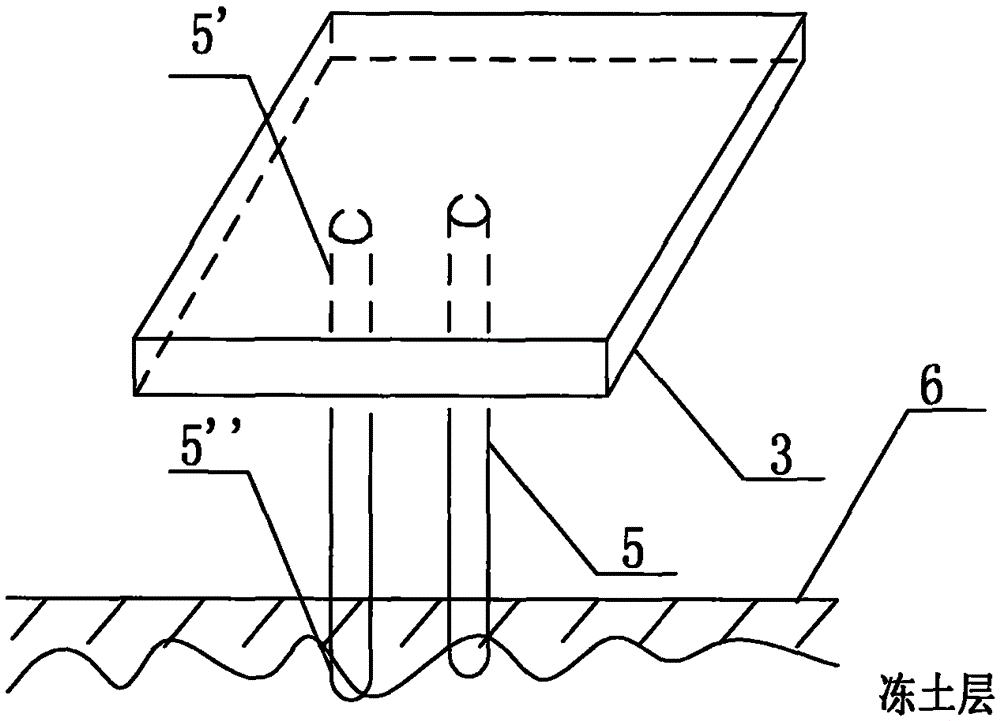

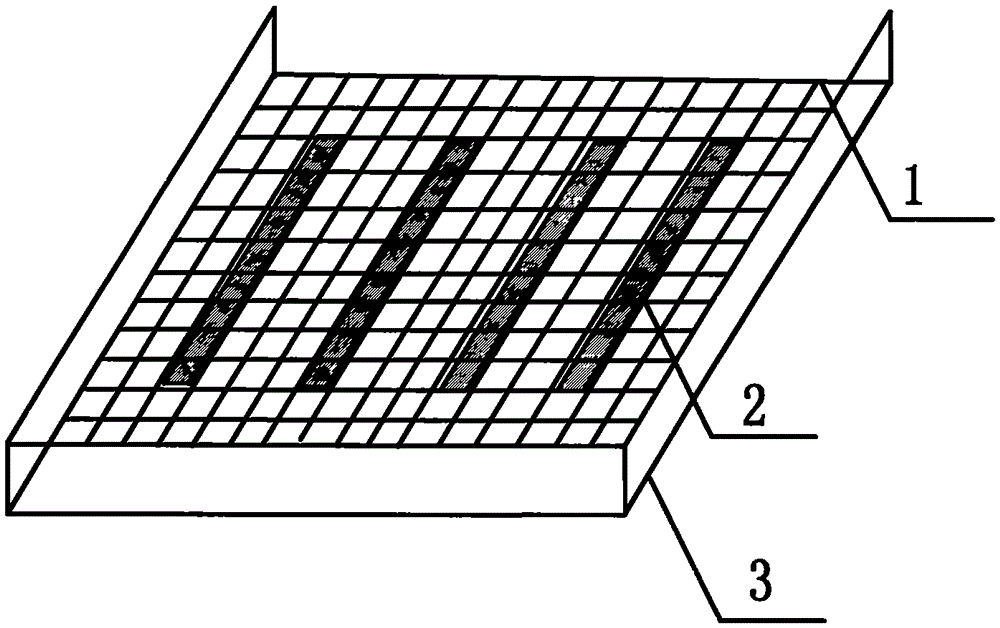

[0036] Such as figure 1 As shown, the system includes: solar panel 1 , phase change material 2 , energy storage board 3 , EVA adhesive 4 , inorganic heat pipe 5 and soil 6 . The energy storage board 3 and the solar battery panel 1 bonded to each other undergo a heat conduction process, and transfer the excessive heat of the solar battery panel 1 to the energy storage board 3, and the phase change material 2 arranged in the energy storage board 3 is heated to When the phase transition temperature is reached, a phase transition from solid to liquid occurs, and the energy storage panel 3 stores a large amount of latent heat, thereby reducing the temperature of the solar battery panel 1 . One end 5' of the inorganic heat pipe 5 is connected to the energy storage plate 3, and the other end 5" of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com