Al-Mg-Mn-Er-Zr aluminum alloy cold-rolled plate and stabilizing process thereof

An aluminum alloy and stabilization technology, applied in the field of non-ferrous metal alloy materials, can solve the problem of few reports of stabilization annealing process, and achieve good resistance to intergranular corrosion and exfoliation corrosion, good mechanical properties, and good corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) The mass percentage is: Mg5.50%, Mn0.63%, Er0.11%, Zr0.02%, unavoidable impurity content <0.5%, the balance is Al 20mm thick Er aluminum-magnesium alloy hot-rolled plate , Annealing at 460°C for 2h, and then hot-rolling the aluminum plate, leaving a 50%-70% cold deformation for the finished plate, and hot-rolling the aluminum plate to 8mm.

[0018] 2) Perform intermediate annealing at 350°C / 2h on the alloy sheet obtained in step 1). The aluminum plate after the intermediate annealing is subjected to multiple passes of cold finish rolling, the reduction of each pass is controlled at 10%-25%, and the cold deformation amount is 50%-70%.

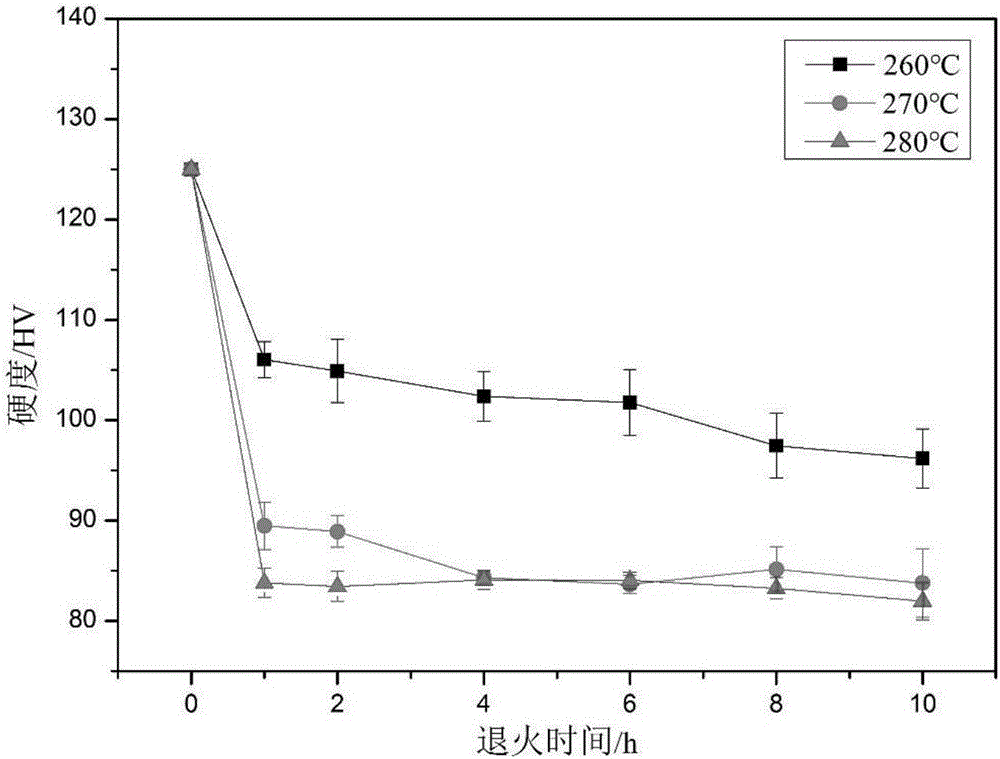

[0019] 3) Step 2) The obtained cold-rolled sheet is annealed at 260°C for different times, and the microhardness of the cold-rolled sheet is measured as the microhardness of the cold-rolled sheet changes with the annealing time, such as figure 1 Shown.

[0020] 4) The difference in step 3) is that the final annealing treatment is performed a...

Embodiment 2

[0023] 1) The mass percentage is: Mg6.0%, Mn0.84%, Zr0.06%, unavoidable impurity content <0.5%, the balance is Al 20mm thick Er-containing aluminum-magnesium alloy hot-rolled sheet, carried out at 460℃ After annealing for 2 hours, the aluminum plate is hot-rolled for hot rolling, leaving a cold deformation of 50%-70% for the finished plate, and the aluminum plate is hot-rolled to 8mm.

[0024] 2) Perform intermediate annealing at 350°C / 2h on the alloy sheet obtained in step 1). The aluminum plate after the intermediate annealing is subjected to multiple passes of cold finish rolling, the reduction of each pass is controlled at 10%-25%, and the cold deformation amount is 50%-70%.

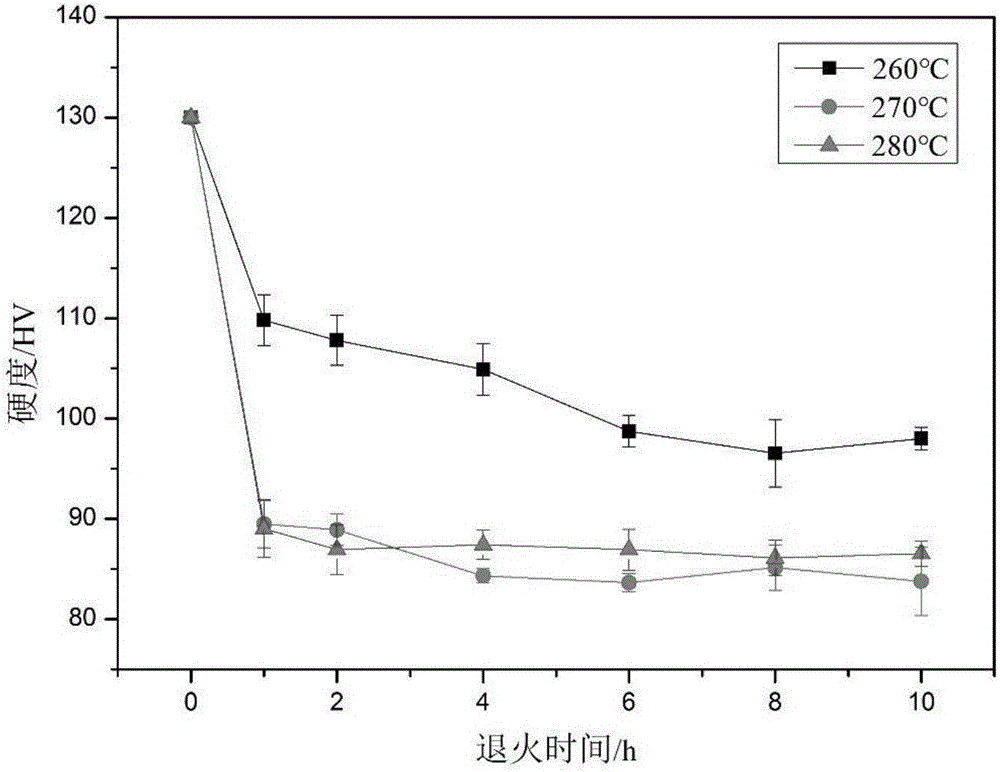

[0025] 3) Step 2) The obtained cold-rolled sheet is annealed at 260°C for different times, and the microhardness of the cold-rolled sheet is measured as the microhardness of the cold-rolled sheet changes with the annealing time, such as figure 2 Shown.

[0026] 4) The difference in step 3) is that the fi...

Embodiment 3

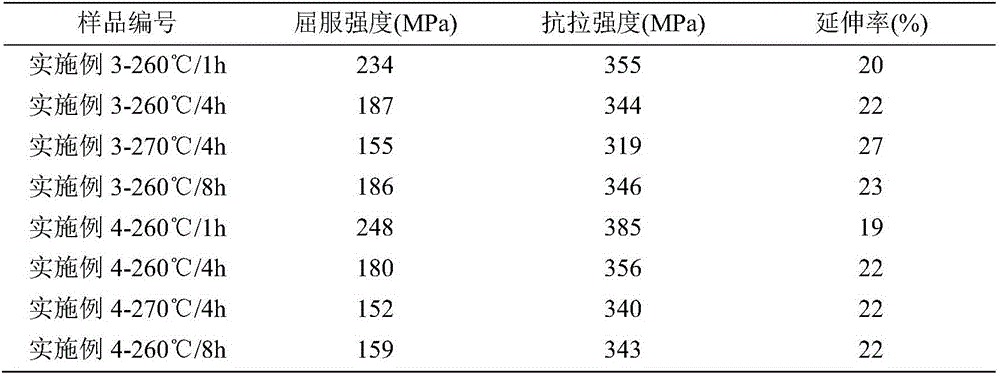

[0030] 1) The cold-rolled sheet obtained in step 2) of Example 1 was annealed at 260°C for 1h / 4h / 8h, respectively. Air-cooled to room temperature, and then the tensile properties of the obtained sheet were tested. The results are shown in Table 1.

[0031] 2) The difference from step 1) of Example 3 is the annealing treatment at 270°C for 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com