A Rotary Extrusion Die for Light Alloy Cup Parts

A technology of extrusion forming and cup-shaped parts, which is applied in the direction of metal extrusion dies, etc., can solve the problems of easy folding or cracking, poor forming effect, etc., and achieves reduction of performance anisotropy, large plastic strain, and enhanced deformation and strengthening. effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

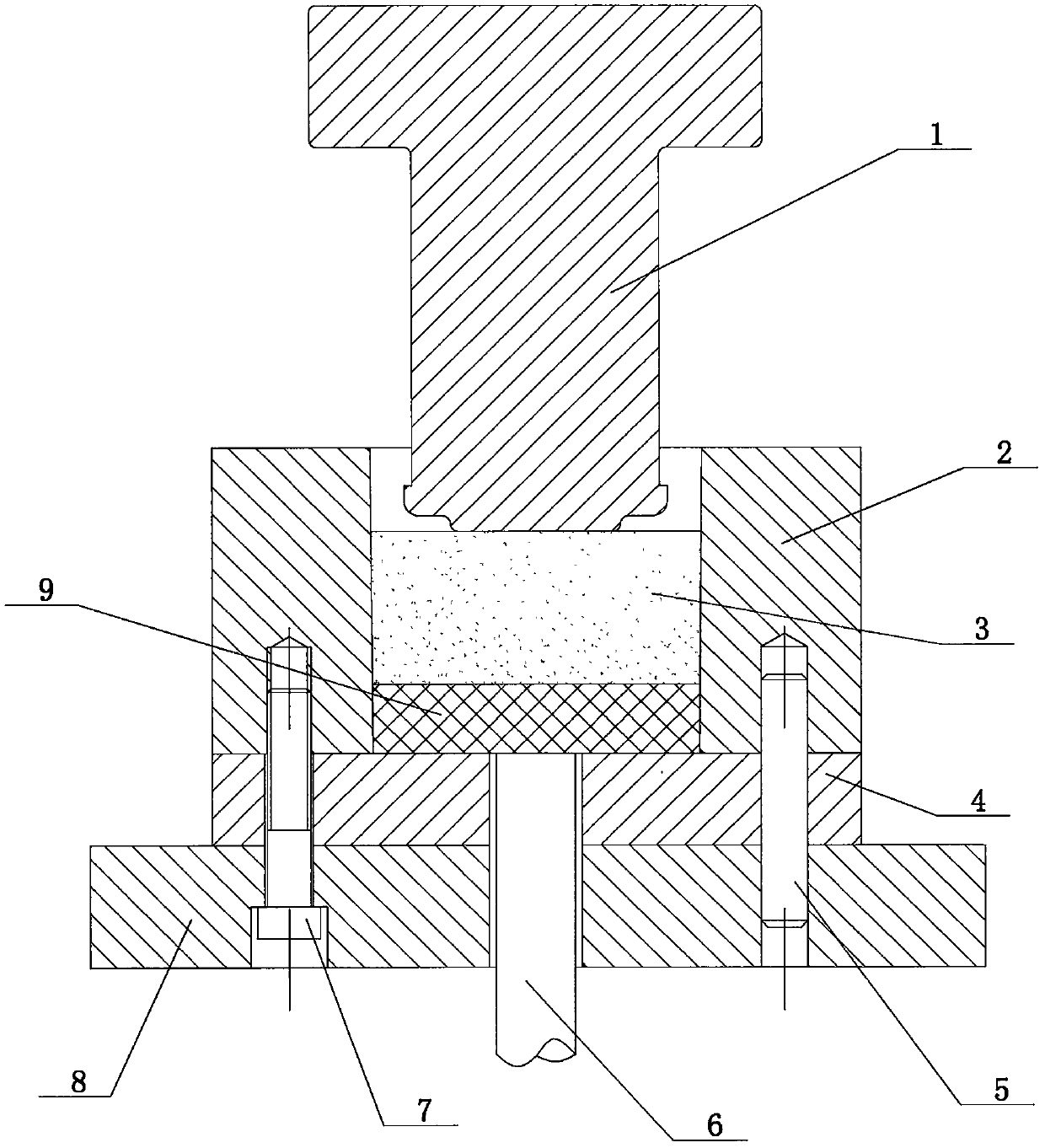

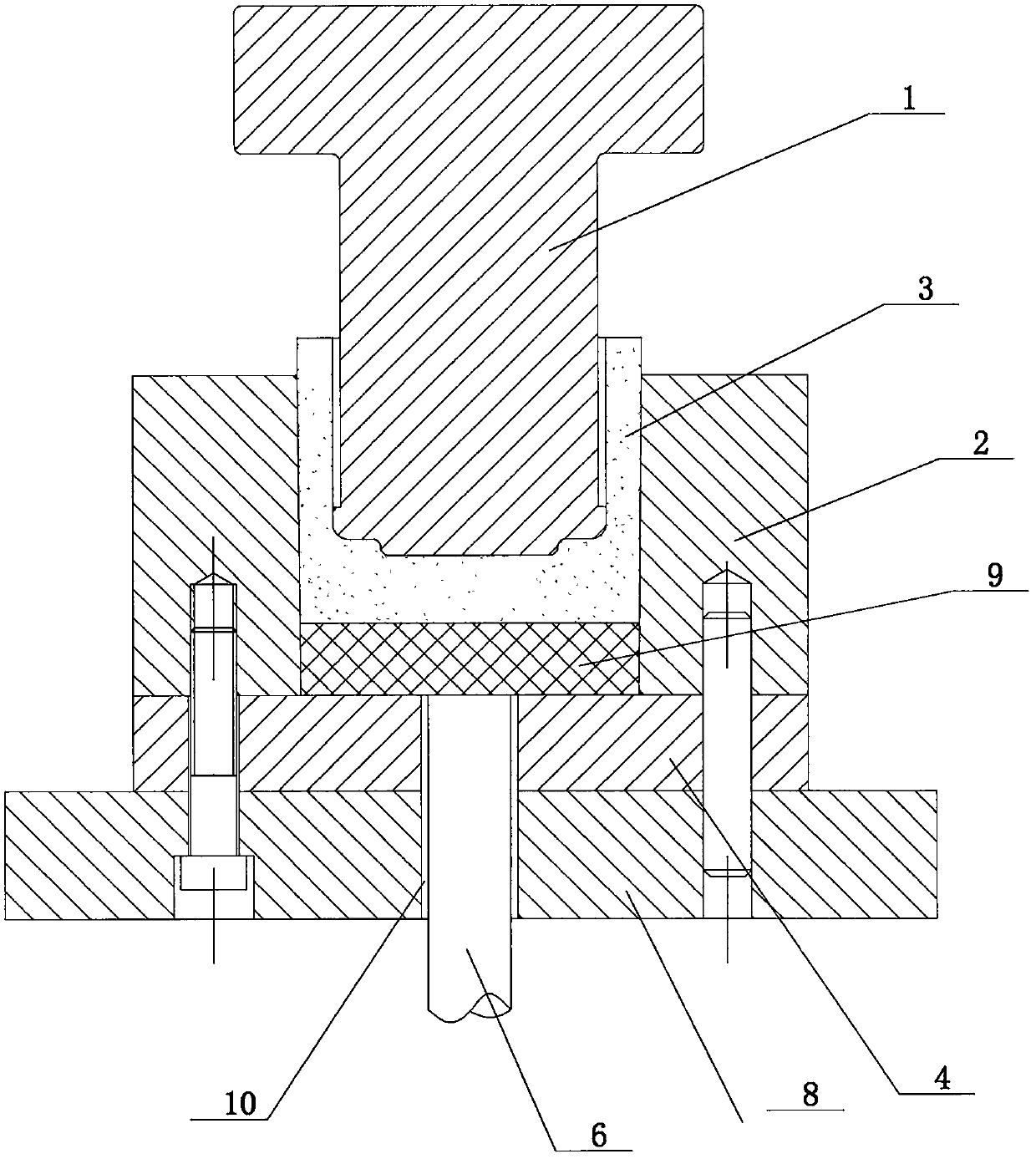

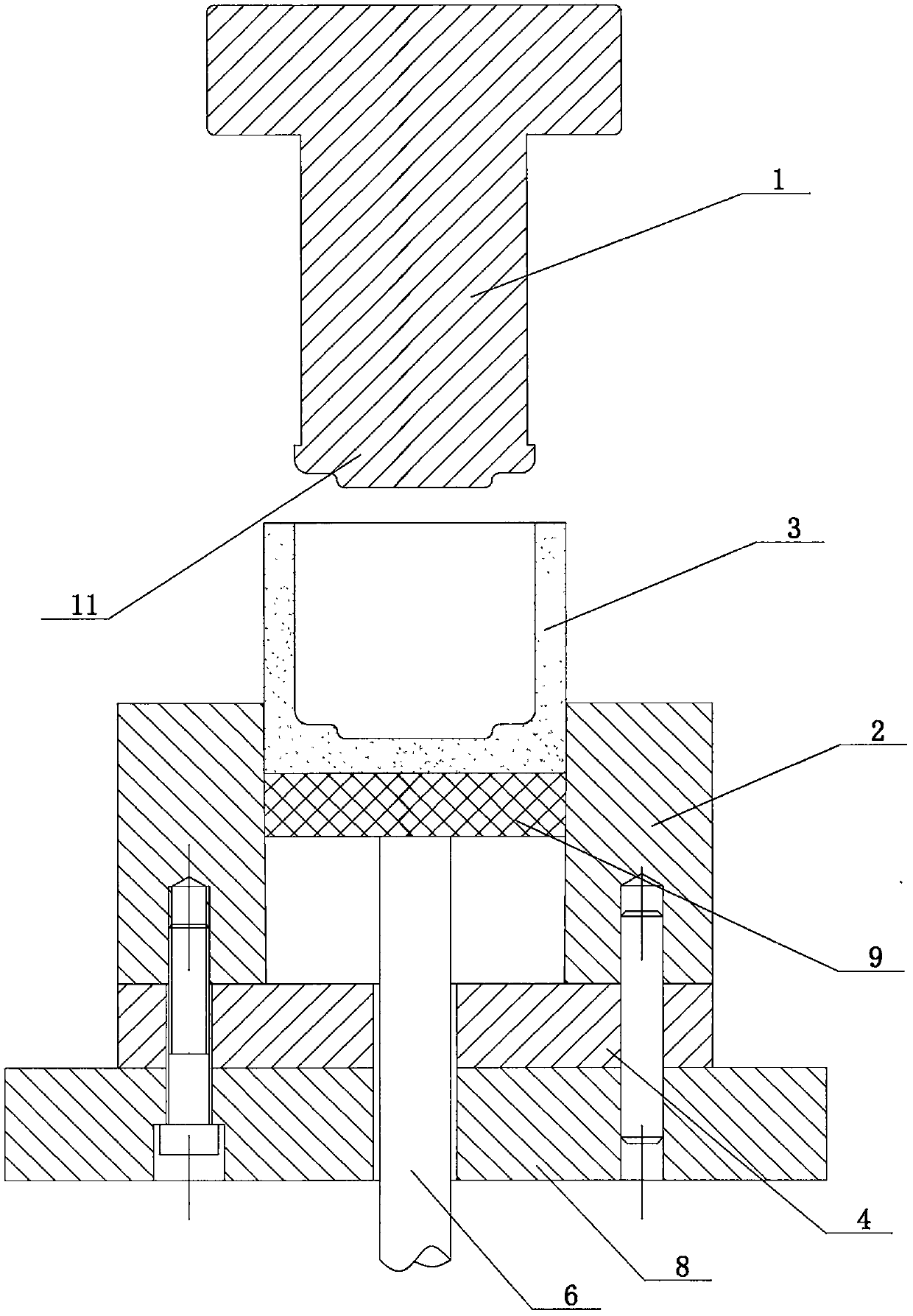

[0039] Using a cylindrical solid blank to prepare 7075 aluminum alloy cups with an outer diameter of 200mm and an inner diameter of 170mm is a specific example, and a method of rotary extrusion forming of a light alloy cup with a "fan"-shaped structure boss die surface is introduced in detail .

[0040] The specific process dimensions of the mold components used in the embodiment are as follows: Figure 7 As shown, the diameter D1 of the working belt 13 of the punch 1 is 170mm, the bottom chamfer R1 of the working belt 13 is 10°, the thickness H1 of the working belt 13 is 20mm, and the inclination angle α0 of the “fan-blade”-shaped boss 14 is 30°. The bottom fillet R0 of the “leaf” shaped boss 14 is 5°; Figure 5 , 7 As shown, R4=D1 / 2=85mm, L0=L1 / 2=15mm, R3=55mm; see Figure 8 As shown, the height of the forming cavity 2 is H2=200mm, the draft angle of the inner cavity side wall is 0.5°, the opening angle of the arc surface groove 12 on the side wall is 120°, and the arc surface g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com