Modified phenol-formaldehyde resin adhesive for wood and preparation method thereof

A phenolic resin glue and modification technology, applied in the field of wood adhesives, can solve the problems of expensive adhesive, hard and brittle glue layer, dark color, etc., and achieve the effect of improving heat resistance, high degree of polymerization, and narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

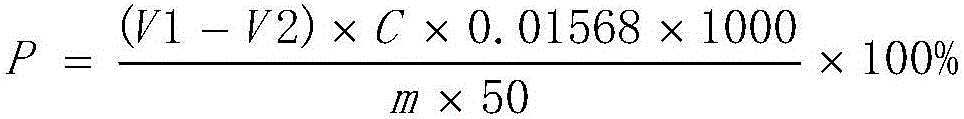

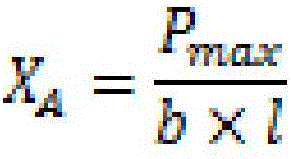

Examples

Embodiment 1

[0021] A modified phenolic resin adhesive for wood is prepared from the following components in parts by weight: 100 parts of phenol, 41 to 55 parts of formaldehyde, 5 to 25 parts of cardanol, 3 to 10 parts of sodium hydroxide, 1 to 5 parts of Parts of modified montmorillonite.

[0022] The preparation method of the modified phenolic resin adhesive for wood includes the following steps: adding molten phenol, cardanol, sodium hydroxide and modified montmorillonite into a three-necked flask at 40-50° C., keeping the temperature for 10-30 minutes; adding Formaldehyde (accounting for 60% of the total formaldehyde), heat up to 50-80°C, keep warm for 50-70min; add the remaining formaldehyde, heat up to 75-80°C, keep warm for 50-70min; heat up to 85-90°C and reflux for 40-60min , rapidly cooled to 40 ~ 50 ℃ and discharged.

[0023] Among them, the total amount of formaldehyde added is 40ml, the amount of phenol added is calculated according to the molar ratio of formaldehyde to phen...

Embodiment 2

[0026] A modified phenolic resin adhesive for wood and a preparation method thereof. The preparation method comprises the following steps: melting phenol, cardanol and a part of sodium hydroxide (accounting for 80% of the total amount of sodium hydroxide) at 40-50° C. ), the modified montmorillonite was added into the three-necked flask, and kept for 10 to 30 minutes; add formaldehyde (accounting for 60% of the total formaldehyde), heat up to 50 to 70 ° C, and keep the temperature for 50 to 70 minutes; add the remaining sodium hydroxide, keep the temperature for 5 ~15min; add the remaining formaldehyde, heat up to 75~80°C, keep the temperature for 50~70min; heat up to 85~90°C and reflux for 40~60min, and rapidly cool to 40~50°C for discharging.

[0027] Among them, the total amount of formaldehyde added is 40ml, the amount of phenol added is calculated according to the molar ratio of formaldehyde to phenol as 1.7:1, the amount of sodium hydroxide added is 5% of phenol, configur...

Embodiment 3

[0030] A modified phenolic resin adhesive for wood and a preparation method thereof, the preparation method comprises the following steps: melting phenol, cardanol, a part of sodium hydroxide (accounting for 80% of the total amount of sodium hydroxide), The modified montmorillonite was added to the three-necked flask, and kept for 20 minutes; formaldehyde (accounting for 60% of the total formaldehyde) was added, the temperature was raised to 60 ° C, and the temperature was kept for 60 minutes; the remaining sodium hydroxide was added, and the temperature was kept for 10 minutes; 80°C, hold the temperature for 60min; heat up to 90°C and reflux for 60min, rapidly cool to 45°C for discharging.

[0031] Among them, the total amount of formaldehyde added is 40ml, the amount of phenol added is calculated according to the molar ratio of formaldehyde to phenol as 1.7:1, the amount of sodium hydroxide added is 5% of phenol, configured as a 20% aqueous solution for use, and the amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com