Surface processing technology for improving GaN HEMT passivation effect and reducing current collapse

A surface treatment and technology technology, applied in the field of microelectronics, can solve the problems of incomplete removal of gallium nitride surface, reduce surface passivation, aggravate current collapse, etc., and achieve the effect of stable thickness, easy control and wide use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, the present invention will be more fully described with reference to the accompanying drawings, so that the technical means, creative features, work flow, and usage methods of the present invention can be easily understood. The described embodiment is only one form of implementation of the invention, ie the invention should not be construed as limited to the embodiments set forth herein. Based on the embodiment, the scope of the present invention is fully conveyed to those skilled in the art.

[0032] Hereinafter, exemplary embodiments of the present invention will be described in more detail with reference to the accompanying drawings. Its preparation method comprises the following specific steps:

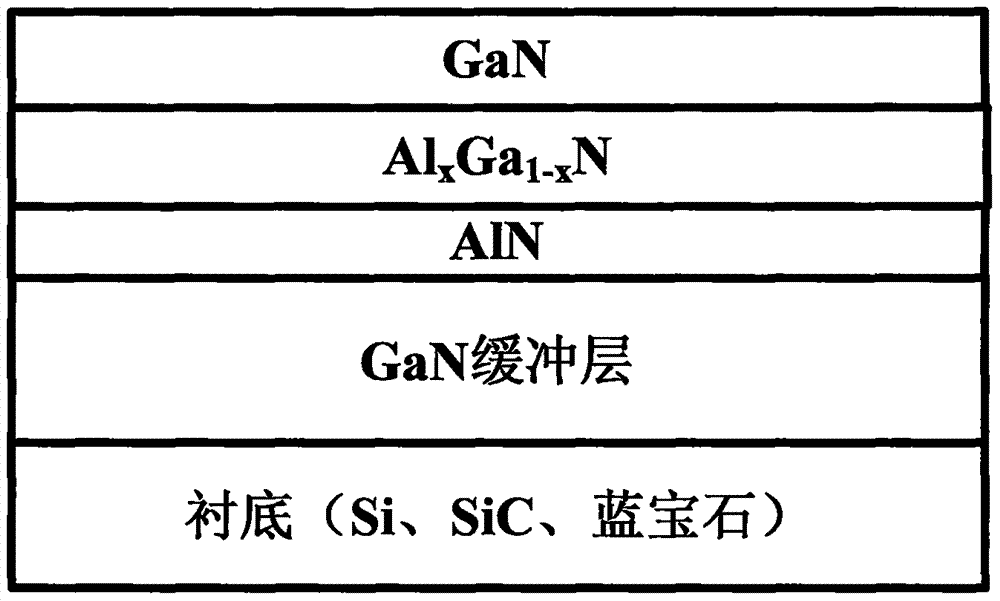

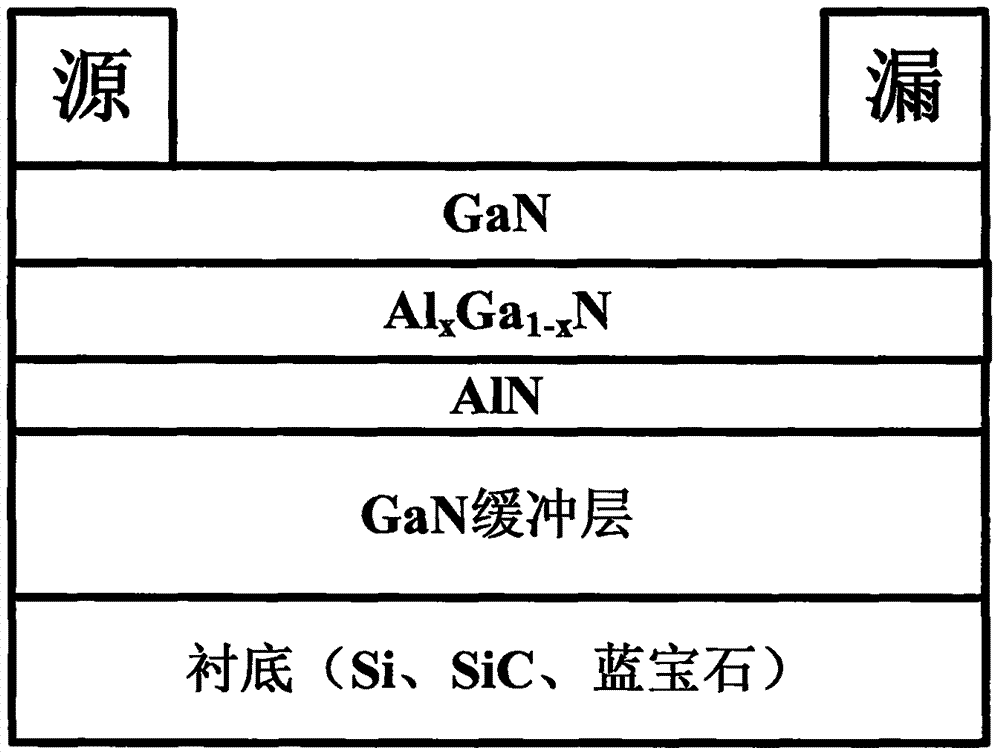

[0033] (1) if figure 1 As shown, on a Si substrate (the substrate can also be SiC or sapphire), a GaN channel layer is first grown by MOCVD, an AlN insertion layer is grown on it, and 24nm AlGaN is grown, and finally GaN is grown Surface capping layer.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com