Etching solution for copper-molybdenum alloy film

A technology of copper-molybdenum alloy film and etching solution, which is applied in the field of metal etching solution, can solve the problems of high processing cost, loss, and large environmental pollution of etching waste solution, and achieve the avoidance of violent decomposition and explosion, low hydrogen peroxide content, and personnel The effect of low operational risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

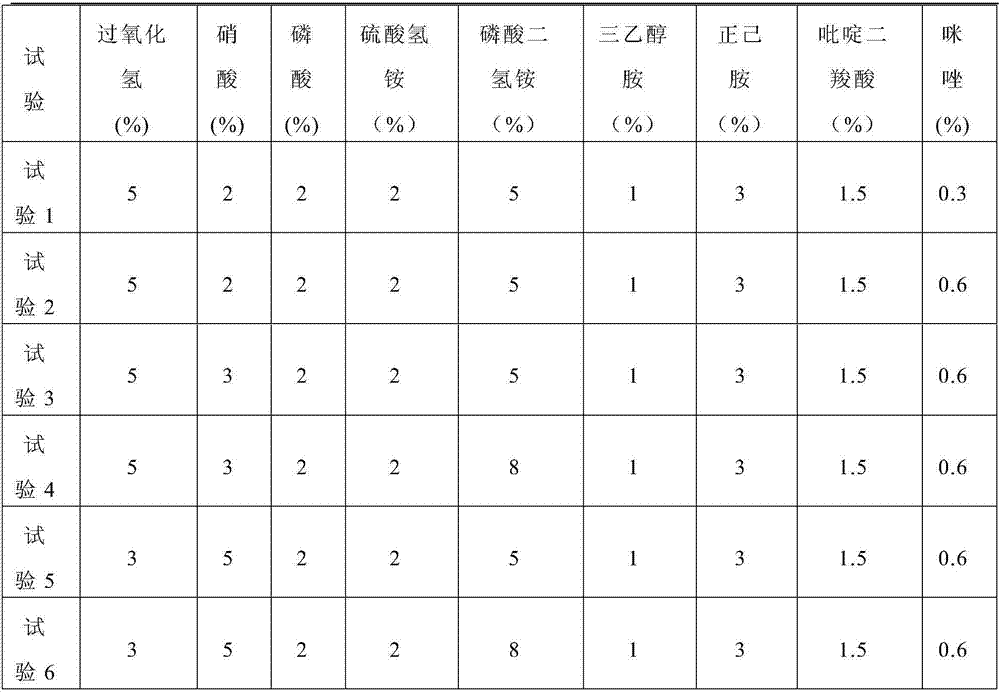

[0023] This embodiment provides an etching solution for a copper-molybdenum alloy film, which is composed of hydrogen peroxide, inorganic acids, sulfates, inorganic ammonium salt buffers, pH regulators of alcohol amines, hydrogen peroxide stabilizers, and metal ion chelating agents. Mixture, metal corrosion inhibitor and deionized water. In this example, inorganic acid adopts nitric acid and phosphoric acid; Sulfate adopts ammonium bisulfate; Inorganic ammonium salt type buffering agent adopts ammonium dihydrogen phosphate; The pH regulator of alcohol amines adopts triethanolamine; Hydrogen peroxide stabilizer adopts n-hexylamine; The metal ion chelating agent adopts dipicolinic acid; the metal corrosion inhibitor adopts imidazole. In this example, experiments were carried out on the dosages of the above components. See Table 1 for details. The percentages in Table 1 are mass percentages, that is, the percentages of the components in the total weight of the etching solution, a...

Embodiment 2

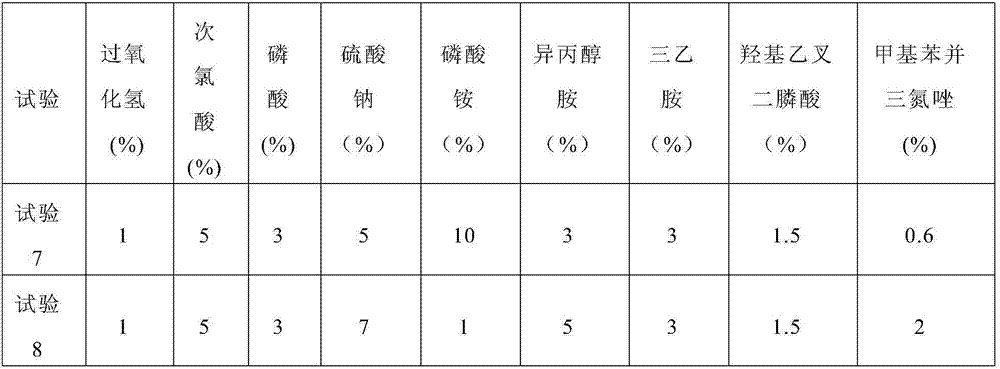

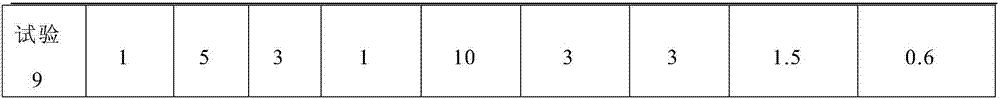

[0027] This embodiment provides an etching solution for a copper-molybdenum alloy film, which is composed of hydrogen peroxide, inorganic acids, sulfates, inorganic ammonium salt buffers, pH regulators of alcohol amines, hydrogen peroxide stabilizers, and metal ion chelating agents. Mixture, metal corrosion inhibitor and deionized water. In this example, inorganic acid adopts hydrochloric acid and phosphoric acid; Sulfate adopts sodium sulfate; Inorganic ammonium salt type buffering agent adopts ammonium phosphate; The pH regulator of alcohol amines adopts isopropanolamine; Hydrogen peroxide stabilizer adopts triethylamine; Hydroxyethylidene diphosphonic acid is used as metal ion chelating agent; methyl benzotriazole is used as metal corrosion inhibitor. In this example, experiments were carried out on the dosages of the above components, see Table 2 for details. The percentages in Table 2 are mass percentages, that is, the percentages of the components in the total weight of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com