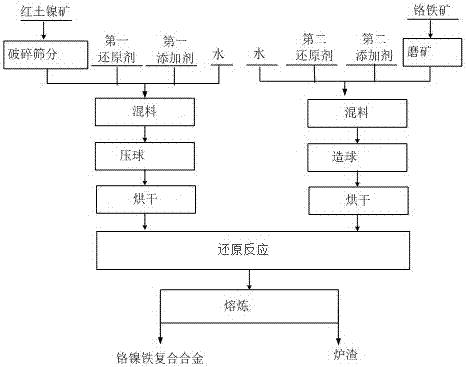

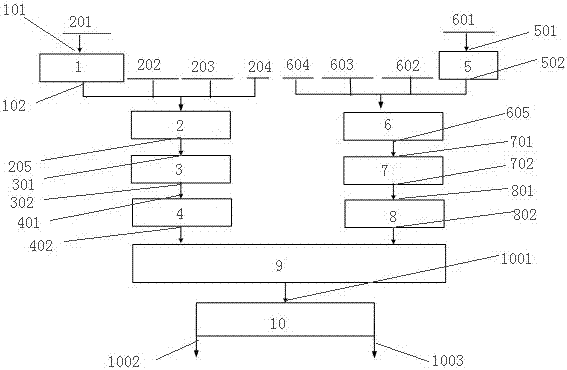

System and method for producing Cr-Ni-Fe composite alloy in double-process pelleting mode

A composite alloy, Inconel technology, applied in the field of metallurgy, can solve the problems affecting product indicators, the thickness of the pellets should not be too thick, and the cost is high, so as to improve the thermal energy utilization rate and production capacity, improve energy utilization rate, energy utilization rate high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1: Put the laterite nickel ore into the crushing and screening device for crushing treatment to obtain granular laterite nickel ore, uniformly mix the granular laterite nickel ore, the first reducing agent, the first additive and water, and use a high-pressure ball press The pellets are elliptical, and the Ni grade of the laterite nickel ore is 1.1%, the particle size of the laterite nickel ore is less than -3mm, of which -1mm accounts for 60%, and the fixed carbon content of semi-coke is 75%. 1.1 times the calculated amount, the particle size of semi-coke is less than -2mm, of which -1mm accounts for 50%, and the addition of limestone is 10%; the pressed laterite nickel ore hydrous pellets are oval, with a size of 33×27×16mm, The moisture content of the pellets is 17%, and they are sent to the dryer for drying treatment to obtain dry lateritic nickel ore pellets with a moisture content of less than 2%; the chromite ore is added to the grinding device for grin...

Embodiment 2

[0067] Embodiment 2: the laterite nickel ore is added into the crushing and screening device for crushing, and the granular laterite nickel ore is obtained with a particle size of less than -3mm, wherein more than 1mm accounts for more than 30% of the total weight. The granular laterite nickel ore, the first The reducing agent, the first additive and water are mixed evenly to obtain the laterite-nickel ore mixed material, and then pressed into elliptical pellets with a ball press machine. The Ni grade of the laterite-nickel ore is 1.6%, and the amount of coal added is the theoretical requirement. 1.2 times, the limestone is added as 8% of the weight of the laterite nickel ore, the laterite nickel ore is pressed into balls, the size of the laterite nickel ore pellets after pressing is 40×30×20mm, and the laterite nickel ore is dried after the pellets are dried Pellets; adding chromite ore to the grinding device for grinding to obtain fine-grained chromite with a particle size of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com