Preparation method and application of a hollow structure composite material based on nickel phosphide

A hollow structure and composite material technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problem of reducing the electrochemical activity of sulfur cathodes, achieve the effects of inhibiting the shuttle effect, enhancing electrochemical activity, and enhancing the depth of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

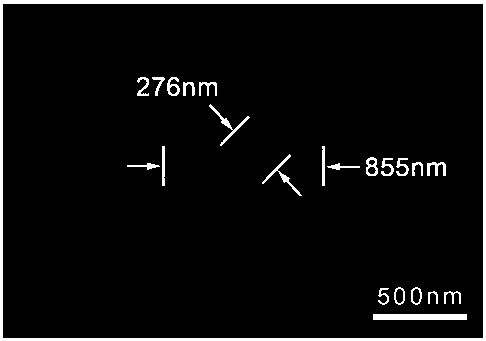

[0024] (1) First, 0.5mmol of nickel sulfate, 100mL of isopropanol, 5mL of glycerin, and 0.5mL of distilled water were prepared into a solution, and transferred to a reaction kettle, and the water was heated in an oven at 90°C for 6 hours. Thermal reaction, the product obtained after the reaction is completed is obtained by centrifugation, and after being washed with ethanol and dried, a Ni-hollow structure material is obtained.

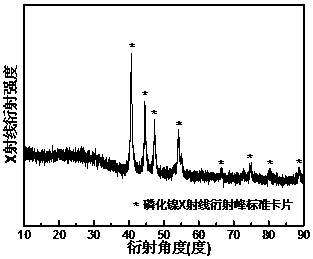

[0025] (2) Mix the dried Ni-hollow structure material with potassium hypophosphite at a mass ratio of 1:1, place in an argon atmosphere tube furnace, and calcinate and phosphate at 250°C for 1 hour to obtain phosphorus Nickel hollow structure material.

[0026] (3) Mix the nickel phosphide hollow structure material obtained in step (2) with the sublimed sulfur at a mass ratio of 1:0.5, grind it evenly, heat it to melt at 120°C for 5 hours under the protection of argon, and then Cool to room temperature to obtain the lithium-sulfur battery cathode mat...

Embodiment 2

[0028] (1) First, make a solution of 1mmol of nickel nitrate, 300mL of n-propanol, 10mL of ethylene glycol, and 5mL of distilled water, and transfer it to a reaction kettle. Thermal reaction, the product obtained after the reaction is completed is obtained by centrifugation, and after being washed with ethanol and dried, a Ni-hollow structure material is obtained.

[0029] (2) Mix the dried Ni-hollow structure material with ammonium hypophosphite at a mass ratio of 1:20, place it in a helium atmosphere tube furnace, and calcinate and phosphate it at 400°C for 6 hours to obtain phosphorus Nickel hollow structure material.

[0030] (3) Mix the nickel phosphide hollow structure material obtained in step (2) with the sublimed sulfur at a mass ratio of 1:4, grind it evenly, heat it to melt at 200°C for 12 hours under the protection of helium, and then Cool to room temperature to obtain nickel phosphide hollow structure composite material.

Embodiment 3

[0032] (1) First, 2mmol of nickel acetate, 200mL of n-propanol, 15mL of glycerin, and 10mL of distilled water were prepared into a solution, and transferred to a reaction kettle, and the hydrothermal reaction was carried out in an oven at 140°C and 12 hours. After the reaction, the product obtained was obtained by centrifugation, washed with ethanol, and dried to obtain a Ni-hollow structure material.

[0033] (2) Mix the dried Ni-hollow structure material with red phosphorus at a mass ratio of 1:50, place in a nitrogen atmosphere tube furnace, and calcinate and phosphate at 500°C for 12 hours to obtain nickel phosphide Hollow structural material.

[0034] (3) Mix the nickel phosphide hollow structure material obtained in step (2) with the sublimed sulfur at a mass ratio of 1:9, after grinding evenly, heat to melt at 150°C for 18 hours under nitrogen protection and then cool to room temperature, the nickel phosphide hollow structure composite material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com