Method for constructing tartaric acid coating layer with corrosion protection function on surface of magnesium metal

A corrosion protection, magnesium metal technology, applied in metal material coating process, coating, pharmaceutical formulations, etc., can solve the problems of corrosion damage of magnesium and magnesium alloys, mechanical performance failure of implant materials, etc., to slow down corrosion and promote biological Compatibility, active site reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for constructing a tartaric acid coating with corrosion protection on the surface of pure magnesium, the steps of which are:

[0022] A. Put pure magnesium into Mg(NO 3 ) 2 , 22g / L HNO 3 and 300g / L ethanol pickling solution, ultrasonic cleaning for one minute, then remove the pure magnesium and rinse it with deionized water;

[0023] B. Immerse the pure magnesium obtained in step A in a 3mol / L NaOH solution, and place it in a water bath at 60°C for 12 hours for alkali activation pretreatment, then take out the pure magnesium and rinse it with deionized water repeatedly and dry it ;

[0024] C, prepare the tartaric acid solution of 5g / L, adjust solution pH to 5 with 1mol / L NaOH;

[0025] D. Immerse the pure magnesium obtained in step B in the tartaric acid solution prepared in step C, and place it in a water bath environment at 60°C for 12 hours, then take out the pure magnesium and rinse it with deionized water repeatedly, and dry it in vacuum; A tartaric ...

Embodiment 2

[0029] A method for constructing a tartaric acid coating with corrosion protection on the surface of a magnesium alloy, the steps of which are:

[0030] A. Put the magnesium alloy into the Mg(NO 3 ) 2 , 22g / L HNO 3 and 300g / L ethanol pickling solution, ultrasonic cleaning for one minute, then remove the magnesium alloy and rinse it with deionized water;

[0031] B. Immerse the magnesium alloy obtained in step A in a 3mol / L NaOH solution, and place it in a water bath at 50°C for 11 hours, perform alkali activation pretreatment, then take out the magnesium alloy and rinse it repeatedly with deionized water and dry it ;

[0032] C, prepare the tartaric acid solution of 15g / L, adjust solution pH to 7 with 1mol / L NaOH;

[0033] D. Immerse the magnesium alloy obtained in step B in the tartaric acid solution prepared in step C, and place it in a water bath environment at 30°C for 6 hours, then take out the magnesium alloy and rinse it repeatedly with deionized water, and dry it i...

Embodiment 3

[0035] A method for constructing a nano-capacity structure on the surface of pure magnesium and covering functional molecules, the steps of which are:

[0036] A. Put pure magnesium into Mg(NO 3 ) 2 , 22g / L HNO 3 and 300g / L ethanol pickling solution, ultrasonic cleaning for one minute, then remove the pure magnesium and rinse it with deionized water;

[0037] B. Immerse the pure magnesium obtained in step A in 3mol / L NaOH solution, and place it in a water bath environment at 70°C for 14 hours, perform alkali activation pretreatment, then take out the pure magnesium and rinse it with deionized water repeatedly and dry it ;

[0038] C, the tartaric acid solution of preparation 25g / L, regulate solution pH to 9 with 1mol / L NaOH;

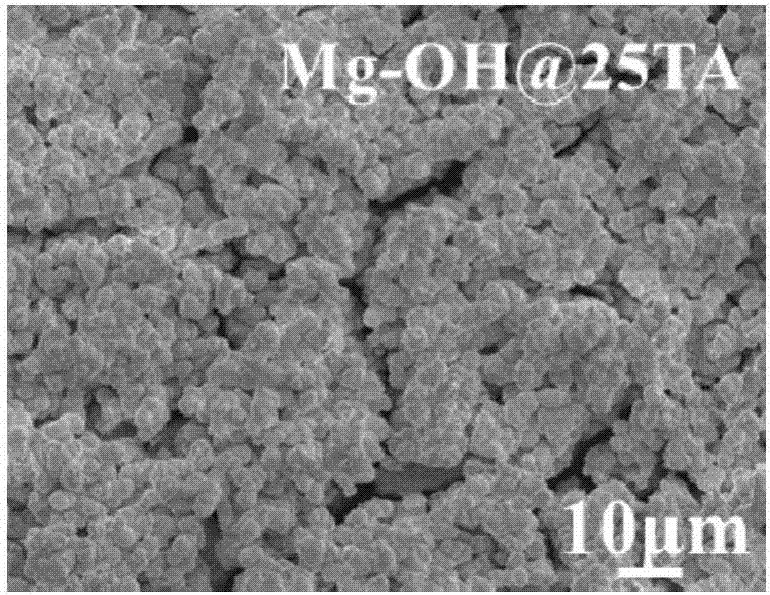

[0039] D. Immerse the pure magnesium obtained in step B in the tartaric acid solution prepared in step C, and place it in a water bath environment at 80°C for 3 hours, then take out the pure magnesium and rinse it repeatedly with deionized water, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com