High-temperature-resistant water-based aramid coating lithium ion battery diaphragm and preparation method thereof

A lithium-ion battery, high-temperature-resistant technology, applied to battery components, circuits, coatings, etc., to achieve good overall performance, reduce adverse effects, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A high-temperature-resistant water-based aramid-coated lithium-ion battery diaphragm, comprising a base film with a coating slurry adhered to one or both sides of the film surface, the base film is a PP diaphragm, and the coating slurry is calculated by mass percentage, Including nano aramid powder 5%, acrylic adhesive 3%, fluorocarbon surfactant and cellulose ether dispersant 1%, agarin 0.02%, phthalate diester 0.03%, trimethylolpropane Tripropionate 0.03%, the balance is deionized water.

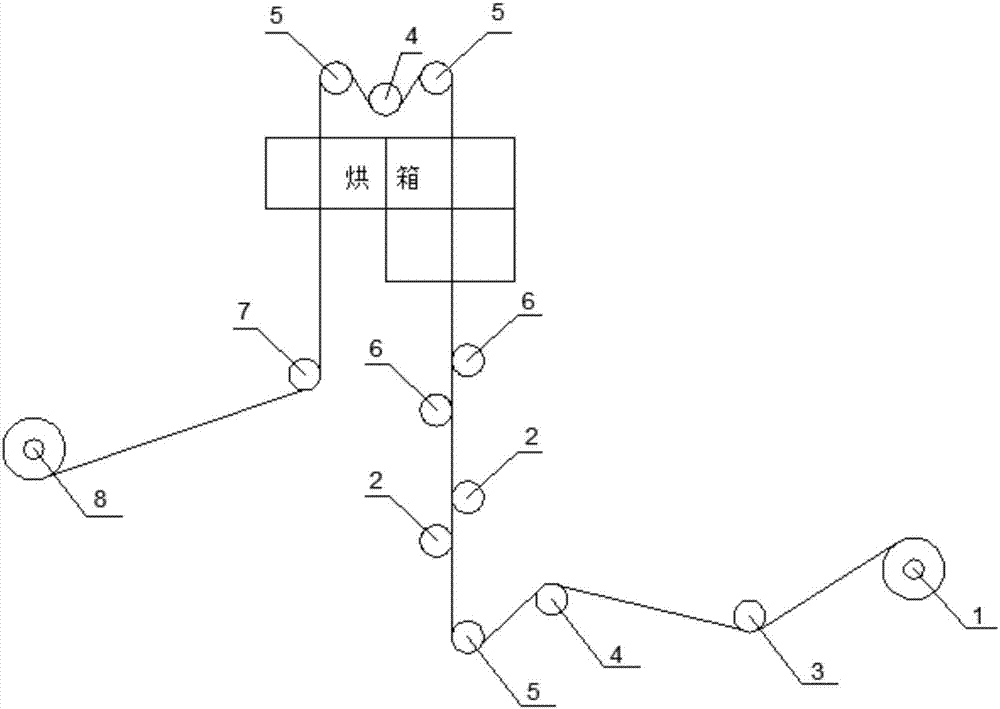

[0031]The above-mentioned high-temperature-resistant water-based aramid-coated lithium-ion battery separator is prepared by the following method, using a vertical double-sided coating machine or a horizontal high-speed coating machine, and the coating device includes a base film unwinding shaft 1 and a rubber coating roller arranged in sequence 2. The heating and drying mechanism and the reel 8, the base film is wound on the base film unwinding reel 1, one end of the base film protr...

Embodiment 2

[0037] A high-temperature-resistant water-based aramid-coated lithium-ion battery separator, comprising a base film with a coating slurry adhered to one or both sides of the film surface, the base film is a fiber separator, and the coating slurry is calculated by mass percentage. Including nano aramid powder 20%, acrylic adhesive 7%, fluorocarbon surfactant and cellulose ether dispersant 4%, agarin 0.02%, phthalate diester 0.07%, trimethylolpropane Tripropionate 0.08%, the balance is deionized water.

[0038] The above-mentioned high-temperature-resistant water-based aramid-coated lithium-ion battery separator is prepared by the following method, using a vertical double-sided coating machine or a horizontal high-speed coating machine, and the coating device includes a base film unwinding shaft 1 and a rubber coating roller arranged in sequence 2. The heating and drying mechanism and the reel 8, the base film is wound on the base film unwinding reel 1, one end of the base film ...

Embodiment 3

[0044] A high-temperature-resistant water-based aramid-coated lithium-ion battery diaphragm, comprising a base film with coating slurry adhered to one or both sides of the film surface, the base film is a non-woven diaphragm, and the coating slurry is based on mass percentage Total, including 10% nano aramid powder, 9% acrylic adhesive, 2% fluorocarbon surfactant and cellulose ether dispersant, 0.03% agarin, 0.1% phthalate diester, trimethylol 0.1% propane tripropionate, and the balance is deionized water.

[0045] The above-mentioned high-temperature-resistant water-based aramid-coated lithium-ion battery separator is prepared by the following method, using a vertical double-sided coating machine or a horizontal high-speed coating machine, and the coating device includes a base film unwinding shaft 1 and a rubber coating roller arranged in sequence 2. The heating and drying mechanism and the reel 8, the base film is wound on the base film unwinding reel 1, one end of the base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unwind tension | aaaaa | aaaaa |

| Unwind tension | aaaaa | aaaaa |

| Unwind tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com