Processing method of fermented-soybean-flavor air-dried marinated beef

A processing method and aroma technology, applied in the functions of food ingredients, food ingredients containing natural extracts, food science, etc., can solve the problems of reduced water holding capacity, increased salt consumption, etc., to eliminate fishy odor and prolong storage period. , the effect of unique soy flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

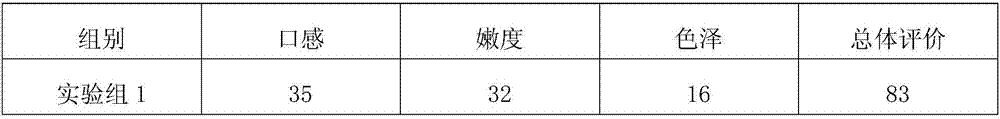

Examples

Embodiment 1

[0028] A kind of processing method of soya-flavored dried beef, comprising the following steps:

[0029] (1) Pretreatment: After slaughtering healthy and live cattle, place them in a cooling room at a temperature of 0-4°C for 12 hours for acid discharge treatment; during the acid discharge process, control the humidity in the cooling room to 75-85%, and the ventilation speed to 3m / s. After the deacidification treatment, select the yellow cattle buttock meat, wash the blood, and cut into raw beef pieces with a length of 8-12cm, a width of 5-8cm, and a thickness of 5-8cm;

[0030] (2) Preparation of pickling solution: Weigh 20 parts of barley, 18 parts of burdock, 18 parts of ginkgo, 15 parts of rock bamboo shoots, 6 parts of thorn berries, 15 parts of malt, 10 parts of rehmannia glutinosa, and 8 parts of dodder seed by weight; wash them clean Finally, soak for 20 minutes with water whose weight is 5 times the total weight of all raw materials, boil, then simmer for 25 minutes...

Embodiment 2

[0037] A kind of processing method of soya-flavored dried beef, comprising the following steps:

[0038] (1) Pretreatment: After slaughtering the healthy and live cattle, place them in a cooling room at a temperature of 0-4°C for 18 hours for acid discharge treatment; during the acid discharge process, control the humidity in the cooling room to 75-85%, and the ventilation speed to 4m / s. After the deacidification treatment, select the yellow cattle buttock meat, wash the blood, and cut into raw beef pieces with a length of 8-12cm, a width of 5-8cm, and a thickness of 5-8cm;

[0039] (2) Preparation of pickling liquid: weigh 25 parts of barley, 20 parts of burdock, 22 parts of ginkgo, 16 parts of rock bamboo shoots, 10 parts of thorn berries, 18 parts of malt, 12 parts of rehmannia glutinosa, and 9 parts of dodder seed by weight; clean Finally, soak for 25 minutes with water whose weight is 6 times the total weight of all raw materials, boil, then simmer for 26 minutes on low h...

Embodiment 3

[0046] A kind of processing method of soya-flavored dried beef, comprising the following steps:

[0047] (1) Pretreatment: After slaughtering healthy and live cattle, place them in a cooling room at a temperature of 0-4°C for 24 hours for acid discharge treatment; during the acid discharge process, control the humidity in the cooling room to 75-85%, and the ventilation speed to 4m / s. After the deacidification treatment, select the yellow cattle buttock meat, wash the blood, and cut into raw beef pieces with a length of 8-12cm, a width of 5-8cm, and a thickness of 5-8cm;

[0048] (2) Preparation of pickling solution: weigh 30 parts of barley, 25 parts of burdock, 25 parts of ginkgo, 18 parts of rock bamboo shoots, 12 parts of thorn berries, 20 parts of malt, 15 parts of rehmannia glutinosa, and 12 parts of dodder seed by weight; clean Finally, soak for 30 minutes with water whose weight is 8 times the total weight of all raw materials, boil, then simmer for 30 minutes on low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com