Processing device of fish fillets

A processing device and technology for fish fillets, which are applied in fish processing hand tools, fish processing, devices for coating liquid on the surface, etc., can solve problems such as difficult cleaning, low efficiency, and uneven thickness of fish fillets, and improve accuracy , Guarantee the effect of consistent and excellent temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

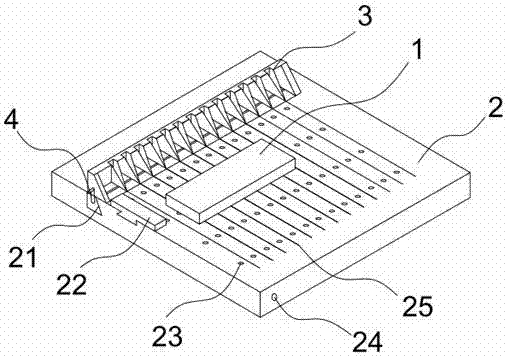

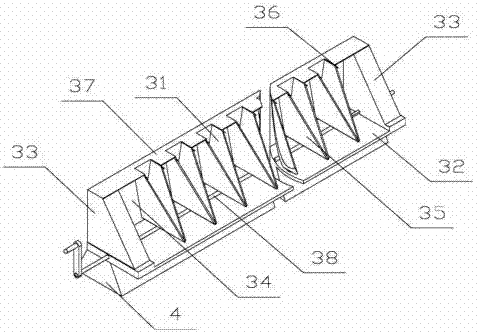

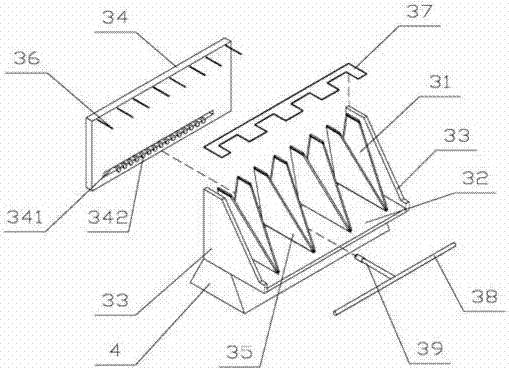

[0023] like Figure 1~3 As shown, a processing device for fish fillets includes a platen 2, a limiting block 3 provided at one end of the platen, and evenly distributed drainage holes 23 and slots 25 are arranged on the surface of the platen 2, and the limiting block 3 passes through the locking slot 21 1. The clip 4 is connected with the platen 2, the limiting block 3 is provided with a triangular groove 31, the triangular groove 31 is connected with the blade, the blade edge corresponds to the guide groove 25, and the limiting block 3 is provided with a plurality of Y axes for blade positioning And a triangular groove 31 with an open top, the limiting block 3 includes a bottom plate 32, a back plate 34 and a side plate 33, the side plates 33 are arranged on both sides of the bottom plate 32, the back plate 34 is arranged on the rear side of the bottom plate, and the bottom surface of the bottom plate 32 is connected with the clip 4 , the bottom of the backboard 34 is provide...

Embodiment 2

[0026] like Figure 1~3 As shown, a processing device for fish fillets includes a platen 2, a limiting block 3 provided at one end of the platen, and evenly distributed drainage holes 23 and slots 25 are arranged on the surface of the platen 2, and the limiting block 3 passes through the locking slot 21 1. The clamp bar 4 is connected with the platen 2, the limiting block 3 is provided with a triangular groove 31, and the triangular groove 31 is connected with the blade, and the limiting block 3 is provided with a plurality of triangular grooves 31 which are used for positioning the blade in the Y axis and have an open top. The limiting block 3 includes a base plate 32, a back plate 34 and a side plate 33. The side plates 33 are placed on both sides of the base plate 32, the back plate 34 is placed on the rear side of the base plate, the bottom surface of the base plate 32 is connected with the clip 4, and the bottom of the back plate 34 is provided with an adjustment The slot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com