Smelting system and smelting method for mother liquid of stainless steel

A technology of stainless steel and mother liquor, which is applied to the improvement of process efficiency, furnace type, furnace, etc., can solve the problems of high production cost, low production operation rate, high energy consumption of smelting, easy to achieve ratio, reduce energy consumption and raw material cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

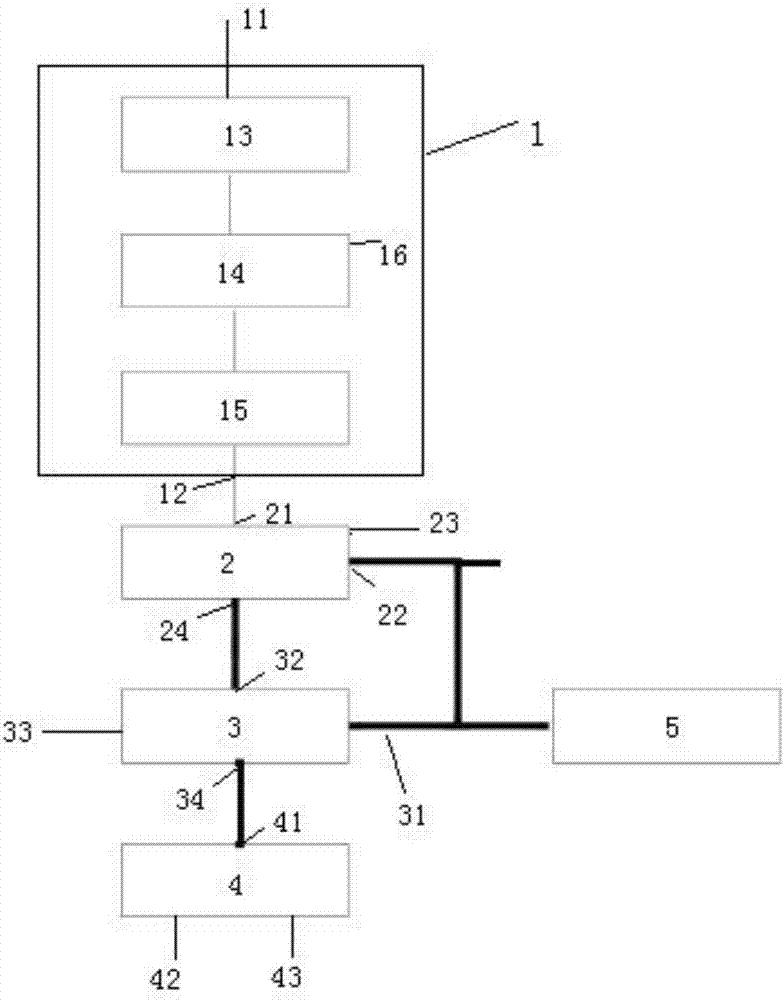

Image

Examples

Embodiment 1

[0066] Chromite, iron concentrate, reducing agent, and binder are used as smelting raw materials, of which chromite (Cr 2 o 3 content is 43.69%, TFe content is 19.28%), iron concentrate (hematite, TFe is 51.45%), reducing agent, binder (bentonite) mass ratio is 100 parts: 100 parts: 70 parts: 13 parts; The particle size of chromite is 0.15mm-0.074mm, accounting for 38%, and below 0.074mm accounts for 30%. Semi-coke, whose particle size is below 0.074mm, accounts for 72%, and its fixed carbon is 75.44%. The above-mentioned raw materials are fed into the mixing device according to the proportion of the batching device, first dry mixed, then wet mixed with water, mixed and sent to the ball pressing device for molding, after being dried by 400 ° C dry gas, transported and distributed into the rotary hearth furnace , Reduction roasting at 1430 ° C to obtain metallized pellets. The hot metallized pellets are sent to the electric furnace and melted at 1720°C. After the slag and ir...

Embodiment 2

[0068] The smelting method of present embodiment stainless steel mother liquor is identical with embodiment 1 step, but process parameter is different, specifically as follows:

[0069] Chromite, iron concentrate, reducing agent, and binder are used as smelting raw materials, of which chromite (Cr 2 o 3 content is 43.69%, TFe content is 19.28%), iron concentrate (hematite, TFe is 51.45%), reducing agent, binder (bentonite) mass ratio is 100 parts: 200 parts: 96 parts: 19 parts; The particle size of chromite is 0.15mm-0.074mm, accounting for 30%, and below 0.074mm accounts for 15%. Semi-coke, whose particle size is below 0.074mm, accounts for 72%, and its fixed carbon is 75.44%. The above-mentioned raw materials are fed into the mixing device according to the proportion of the batching device, first dry mixed, then wet mixed with water, mixed and sent to the ball pressing device for molding, after being dried by 300 ° C dry gas, transported and distributed into the rotary hea...

Embodiment 3

[0071] The smelting method of present embodiment stainless steel mother liquor is identical with embodiment 1 step, but process parameter is different, specifically as follows:

[0072] Chromite, iron concentrate, reducing agent, and binder are used as smelting raw materials, of which chromite (Cr 2 o 3 content is 40.69%, TFe content is 21.24%), iron concentrate (hematite, TFe is 51.45%), reducing agent, binder (bentonite) mass ratio is 100 parts: 140 parts: 74 parts: 16 parts; The particle size of chromite is 0.15mm-0.074mm, accounting for 45%, and below 0.074mm accounts for 25%; the particle size of iron concentrate is 0.15mm-0.074mm, accounting for 30%, below 0.074mm, accounting for 40%. Anthracite, whose particle size is less than 0.074mm, accounts for 65%, and its fixed carbon is 80.56%. The above-mentioned raw materials are fed into the mixing device according to the ratio of the batching device, first dry mixed, then wet mixed with water, and then sent to the ball pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com