Manufacturing process of household daily anti-microbial non-woven fabric

A technology of non-woven fabrics and manufacturing process, applied in the field of non-woven fabrics, can solve problems such as easy to hide dirt, concerns about product environmental protection, and insufficient antibacterial performance of microfiber rags, and achieve the effect of improving antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

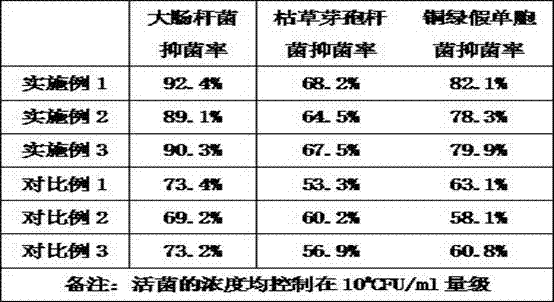

Examples

Embodiment 1

[0037] A kind of manufacturing process of antibacterial nonwoven fabric for daily use at home, is characterized in that, comprises the following steps:

[0038] S1. Raw material preparation: select Vistamaxx VM6202 POE elastomer as the main material, and add 4% total amount of PP material and 0.01‰ total amount of nano-silver powder to make polymer slices, and control the moisture content of the slices to be less than 4%;

[0039] S2. Feed melting: feed the chips into the screw extruder for melting and extrusion, and add slip agent to the screw extruder. The diameter of the screw is 120 mm, the length-to-diameter ratio of the screw is 30, and the temperature of the feeding section is 190°C, the temperature in the compression section is 230°C, and the screw speed is controlled at 40r / min;

[0040] S3. Filtration and spinning: the melt passes through the melt filter, the filtration accuracy is 30±10um, the filter diameter is 200mm, the pressure before filtration is 1.68MPa, and ...

Embodiment 2

[0048] A kind of manufacturing process of antibacterial nonwoven fabric for daily use at home, is characterized in that, comprises the following steps:

[0049] S1. Raw material preparation: select Vistamaxx VM6202 POE elastomer as the main material, and add 4% total amount of PP material and 0.01‰ total amount of nano-silver powder to make polymer slices, and control the moisture content of the slices to be less than 4%;

[0050] S2. Feed melting: feed the chips into the screw extruder for melting and extrusion, and add slip agent to the screw extruder. The diameter of the screw is 120 mm, the length-to-diameter ratio of the screw is 30, and the temperature of the feeding section is 190°C, the temperature in the compression section is 230°C, and the screw speed is controlled at 40r / min;

[0051] S3. Filtration and spinning: the melt passes through the melt filter, the filtration accuracy is 30um, the filter diameter is 200mm, the pressure before filtration is 2MPa, and the pr...

Embodiment 3

[0059] A kind of manufacturing process of antibacterial nonwoven fabric for daily use at home, is characterized in that, comprises the following steps:

[0060] S1. Raw material preparation: select Vistamaxx VM6202 POE elastomer as the main material, and add 4% total amount of PP material and 0.01‰ total amount of nano-silver powder to make polymer slices, and control the moisture content of the slices to be less than 4%;

[0061] S2. Feed melting: feed the chips into the screw extruder for melting and extrusion, and add slip agent to the screw extruder. The diameter of the screw is 120 mm, the length-to-diameter ratio of the screw is 30, and the temperature of the feeding section is 190°C, the temperature in the compression section is 230°C, and the screw speed is controlled at 40r / min;

[0062] S3. Filtration and spinning: the melt passes through the melt filter, the filtration accuracy is 30um, the filter diameter is 200mm, the pressure before filtration is 1.55MPa, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com