Anti-yellowing and ultraviolet-proof coating

An anti-ultraviolet coating and anti-yellowing technology, which is applied in coatings, anti-fouling/underwater coatings, reflection/signal coatings, etc., can solve the problems of coating yellowing and achieve the effect of improving anti-yellowing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method for an anti-yellowing and anti-ultraviolet coating, comprising the following steps:

[0024] S1. Grinding the zinc oxide powder to the nanometer level through an ultra-fine grinder;

[0025] S2, adding the zinc oxide powder into the glass ionomer cement, stirring and mixing it with an ultrasonic mixer;

[0026] S3. Mix light stabilizer Tinuvin B 75, antioxidant IRGASTAB PUR 68, ethylene glycol, glacial acetic acid, and control the temperature at 5-10°C;

[0027] S4. Mix the product of step S2 and the product of step S3, and rapidly raise the temperature to 80° C. through infrared heating;

[0028] S5. Cool down the temperature of the product in step S4 to normal temperature, and spray it onto the lens through a nozzle to form a 200nm coating.

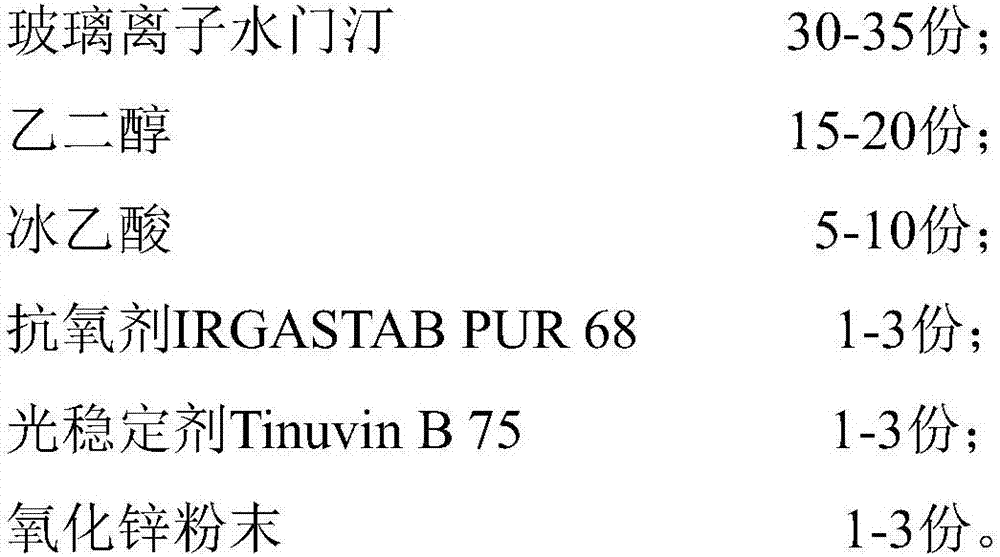

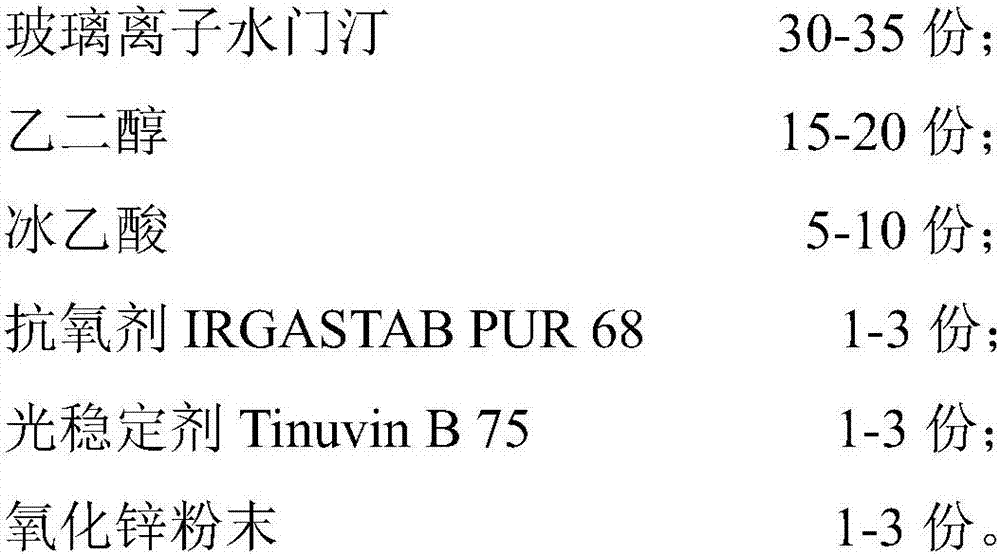

[0029] The content of each of the above components is

[0030] 30 parts of glass ionomer cement; 15 parts of ethylene glycol; 5 parts of glacial acetic acid; 1 part of antioxidant IRGASTAB PUR68; 1 part of...

Embodiment 2

[0032] A preparation method for an anti-yellowing and anti-ultraviolet coating, comprising the following steps:

[0033] S1. Grinding the zinc oxide powder to the nanometer level through an ultra-fine grinder;

[0034] S2, adding the zinc oxide powder into the glass ionomer cement, stirring and mixing it with an ultrasonic mixer;

[0035] S3. Mix light stabilizer Tinuvin B 75, antioxidant IRGASTAB PUR 68, ethylene glycol, glacial acetic acid, and control the temperature at 5-10°C;

[0036] S4. Mix the product of step S2 and the product of step S3, and rapidly raise the temperature to 90° C. through infrared heating;

[0037] S5. Cool down the temperature of the product in step S4 to normal temperature, and spray it onto the lens through a nozzle to form a 300nm coating.

[0038] The content of each of the above components is

[0039] 32 parts of glass ionomer cement; 18 parts of ethylene glycol; 8 parts of glacial acetic acid; 1 part of antioxidant IRGASTAB PUR68; 1 part of...

Embodiment 3

[0041] A preparation method for an anti-yellowing and anti-ultraviolet coating, comprising the following steps:

[0042] S1. Grinding the zinc oxide powder to the nanometer level through an ultra-fine grinder;

[0043] S2, adding the zinc oxide powder into the glass ionomer cement, stirring and mixing it with an ultrasonic mixer;

[0044] S3. Mix light stabilizer Tinuvin B 75, antioxidant IRGASTAB PUR 68, ethylene glycol, glacial acetic acid, and control the temperature at 5-10°C;

[0045] S4. Mix the product of step S2 and the product of step S3, and rapidly raise the temperature to 80° C. through infrared heating;

[0046] S5. Cool down the temperature of the product in step S4 to normal temperature, and spray it onto the lens through a nozzle to form a 200nm coating.

[0047] The content of each of the above components is

[0048] 35 parts of glass ionomer cement; 20 parts of ethylene glycol; 10 parts of glacial acetic acid; 3 parts of antioxidant IRGASTAB PUR68; 3 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com