Quick cooling system capable of protecting inner cylinder and outer cylinder of turbine

A rapid cooling and steam turbine technology, applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problems of slow temperature drop of the inner cylinder and outer cylinder wall of the steam turbine, prolong the maintenance and opening time of the unit, and slow down the natural cooling speed, etc. , to achieve the effect of large air flow, good post-cooling effect and gentle cooling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

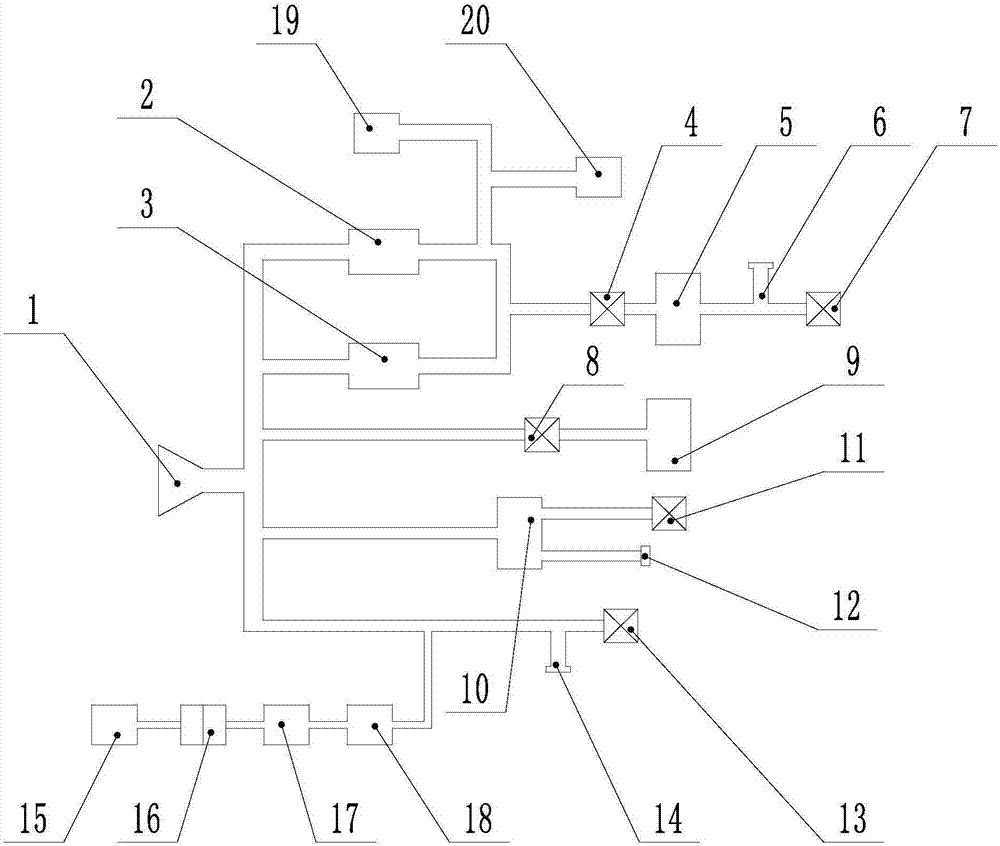

[0025] Such as figure 1 As shown, the present invention is beneficial to protect the rapid cooling system of the inner cylinder and the outer cylinder of the steam turbine, including an air inlet 1, and the air inlet 1 is connected with a parallel automatic main steam valve 2 and a second automatic main steam valve 3, and the first automatic main steam valve Valve 2 and B automatic main steam valve 3 are used to control the steam intake of the steam turbine, and can quickly close and cut off the steam intake in an emergency. The function of the automatic main steam valve is to quickly cut off the steam inlet of the steam turbine and stop the operation of the steam turbine after the protection device of the steam turbine is activated. Therefore, it is the actuator of the protective device. In order to ensure safety, the automatic main steam valve is required to move quickly and close tightly. For high-pressure steam turbines, under normal steam inlet parameters and exhaust ste...

Embodiment 2

[0030] This embodiment is based on Embodiment 1 to further illustrate the present invention.

[0031] Such as figure 1 As shown, the present invention is beneficial to protect the rapid cooling system of the inner cylinder and the outer cylinder of the steam turbine. The check valve-7 is a swing check valve, and the swing check valve is commonly used at the outlet of the water pump, that is, the valve core is suspended on the pin shaft. When the water pump is started, the water pushes the valve core to open to supply water to the outside. When the water pump is stopped, the spool of the check valve is closed under the action of gravity and pressure in the pipeline to prevent the water in the pipeline from pouring back into the pump.

Embodiment 3

[0033] This embodiment is based on Embodiment 1 to further illustrate the present invention.

[0034] Such as figure 1 As shown, the present invention is beneficial to protect the rapid cooling system of the inner cylinder and the outer cylinder of the steam turbine, and the air inlet 1 is also connected with a check valve 2 13 and an exhaust port 14, and an air intake passage is added to make the cylinder cool with a larger The intake air volume, graded air intake is convenient for monitoring and controlling the cooling rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com