Mass production mode of bag cultured volvaria volvacea with spent substrate of pleurotus eryngii

A technique for planting Pleurotus eryngii mushroom chaff and clinker bags, which can be used in mushroom cultivation, cultivation, organic fertilizers, etc., can solve the problems of time-consuming, labor-consuming, energy-consuming, and a large number of labor, so as to reduce production costs, reduce costs, shorten The effect of the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

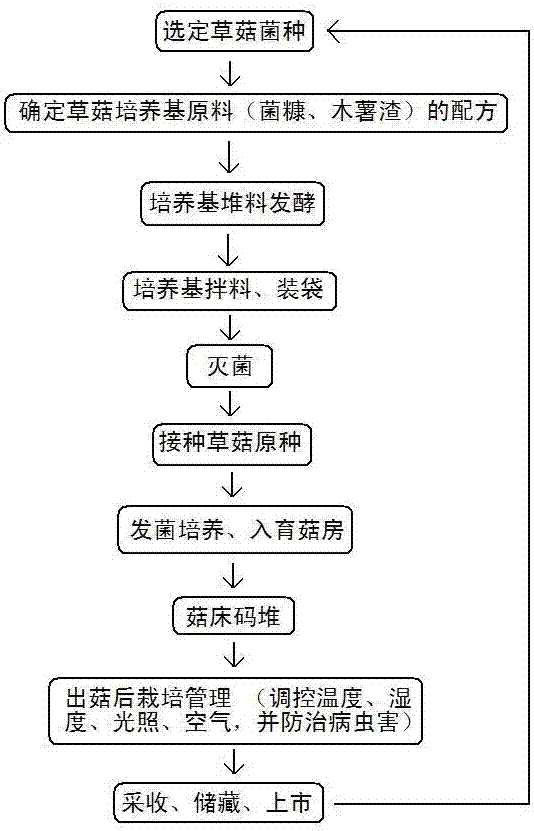

[0086] Such as figure 1 As shown, the production process of the technical solution of the first embodiment is as follows:

[0087] Step 1: Select the strains of straw mushrooms, and select the black excellent varieties of straw mushrooms;

[0088] Step 2: Determine the formula of the raw material for the straw mushroom culture medium, weigh it according to 60% of Pleurotus eryngii mushroom chaff clinker, 20% of cassava residue, 15% of bran, and 5% of lime, and make it by mixing with water at 70% of water content;

[0089] Step 3: The medium is piled for fermentation, the medium volume is 15 cubic meters, the pH value is 11, and the pile is turned three times during the period;

[0090] Step 4: For bagging, use 20cm×45cm polypropylene plastic bags to separate the medium. In order to improve efficiency, mechanical automatic bagging is generally used;

[0091] Step 5: Sterilize the bagged culture medium, the sterilization temperature is 126℃, and the sterilization time is 2 hours;

[0092]...

Embodiment 2

[0099] The production process of the technical solution of the second embodiment is as follows:

[0100] Step 1: Select the strains of straw mushrooms, and select the black excellent varieties of straw mushrooms;

[0101] Step 2: Determine the formula of the raw material for the straw mushroom culture medium, weigh it according to 60% of Pleurotus eryngii mushroom chaff clinker, 20% of cassava residue, 15% of bran, and 5% of lime, and make it by mixing with water at 70% of water content;

[0102] Step 3: The medium is piled for fermentation, the medium volume is 13.3 cubic meters, the pH value is 10, and the pile is turned three times during the period;

[0103] Step 4: Mix and bag the culture medium. Use 20cm×45cm polypropylene plastic to separate the culture medium. In order to improve efficiency, mechanical automatic bagging is generally used. Manual bagging is not recommended;

[0104] Step 5: Sterilize the medium in the bag, the sterilization temperature is 126℃, and the sterilizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com