Rare earth high entropy bulk amorphous alloy with magnetocaloric effect and its preparation process

A technology of amorphous alloy and magneto-caloric effect, applied in the direction of magnetic objects, heat exchange materials, magnetic materials, etc., can solve the problems of reducing magnetic properties and hindering the movement of magnetic domain walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Preparation (La 1 / 6 Ce 1 / 6 Nd 1 / 6 Tb 1 / 6 co 1 / 6 Cu 1 / 6 ) 85.7 Al 14.3 High entropy bulk amorphous alloy

[0044] Step 1: the purity is 99.5wt% La, Ce, Nd, Tb, 99.9wt% Al and 99.9wt% Cu and Co according to (La 1 / 6 Ce 1 / 6 Nd 1 / 6 Tb 1 / 6 co 1 / 6 Cu 1 / 6 ) 85.7 Al 14.3 The atomic percentage is used for batching;

[0045] Step 2: Mix the above ingredients evenly and put them into an electric arc furnace, perform electric arc melting for 4 times in an argon atmosphere adsorbed by titanium to obtain a uniform alloy composition, and cool to obtain a master alloy ingot;

[0046] Step 3: re-melting the master alloy ingot obtained above under the above conditions, using the adsorption device in the electric arc furnace, sucking the master alloy melt into a water-cooled copper mold with an inner diameter of 5 mm to obtain (La 1 / 6 Ce 1 / 6 Nd 1 / 6 Tb 1 / 6 co 1 / 6 Cu 1 / 6 ) 85.7 Al 14.3 High-entropy bulk amorphous alloys.

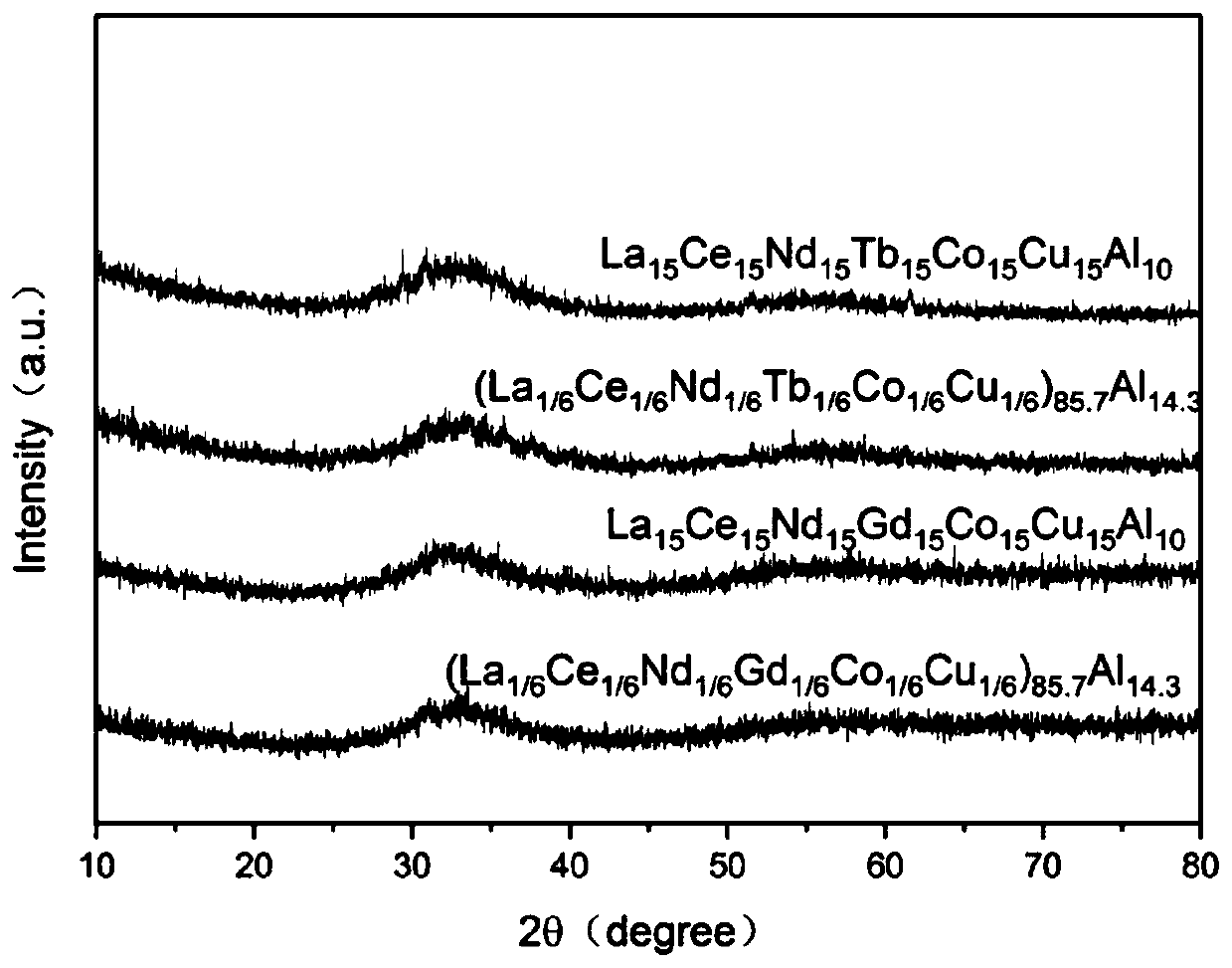

[0047] The structural features of high-entrop...

Embodiment 2

[0049] Embodiment 2: prepare La 15 Ce 15 Nd 15 Tb 15 co 15 Cu 15 Al 10 High entropy bulk amorphous alloy

[0050] Step 1: La, Ce, Nd, Tb with a purity of 99.5wt%, Al of 99.9wt%, and Cu and Co of 99.9wt% according to La 15 Ce 15 Nd 15 Tb 15 co 15 Cu 15 Al 10 Atomic percentage for batching;

[0051] Step 2: Mix the above ingredients evenly and put them into an electric arc furnace, perform electric arc melting 4 times in an argon atmosphere adsorbed by titanium to obtain a uniform alloy composition, and cool to obtain a master alloy ingot;

[0052] Step 3: re-melt the master alloy ingot obtained above under the above conditions, and use the adsorption device in the electric arc furnace to suck the master alloy melt into a water-cooled copper mold with an inner diameter of 5 mm to obtain La 15 Ce 15 Nd 15 Tb 15 co 15 Cu 15 Al 10 High-entropy bulk amorphous alloys.

[0053] The structural features of high-entropy bulk amorphous alloys were detected by X-ray di...

Embodiment 3

[0055] Embodiment 3: preparation (La 1 / 6 Ce 1 / 6 Nd 1 / 6 Gd 1 / 6 co 1 / 6 Cu 1 / 6 ) 85.7 Al 14.3 High entropy bulk amorphous alloy

[0056] Step 1: the purity is 99.5wt% La, Ce, Nd, Gd, 99.9wt% Al and 99.9wt% Cu and Co according to (La 1 / 6 Ce 1 / 6 Nd 1 / 6 Gd 1 / 6 co 1 / 6 Cu 1 / 6 ) 85.7 Al 14.3 Atomic percentage for batching;

[0057] Step 2: Mix the above ingredients evenly and put them into an electric arc furnace, perform electric arc melting 4 times in an argon atmosphere adsorbed by titanium to obtain a uniform alloy composition, and cool to obtain a master alloy ingot;

[0058] Step 3: re-melting the master alloy ingot obtained above under the above conditions, using the adsorption device in the electric arc furnace, sucking the master alloy melt into a water-cooled copper mold with an inner diameter of 5 mm to obtain (La 1 / 6 Ce 1 / 6 Nd 1 / 6 Gd 1 / 6 co 1 / 6 Cu 1 / 6 ) 85.7 Al 14.3 High-entropy bulk amorphous alloys.

[0059] The structural features of high-entropy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com