Method for arranging stainless steel sleeve in large-diameter cylinder block in sleeving way

A stainless steel sleeve, large-diameter technology, applied in the field of surface repair of hydraulic support columns for coal mines, can solve the problems of easy peeling, short service life, easy failure, etc., and achieves the effect of satisfying the finish and size, good adhesion and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention will be further described in detail below.

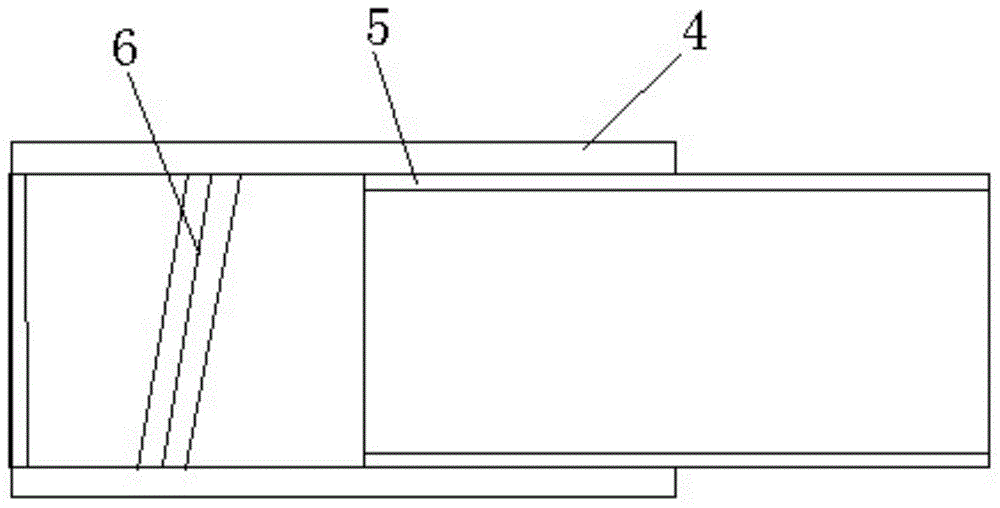

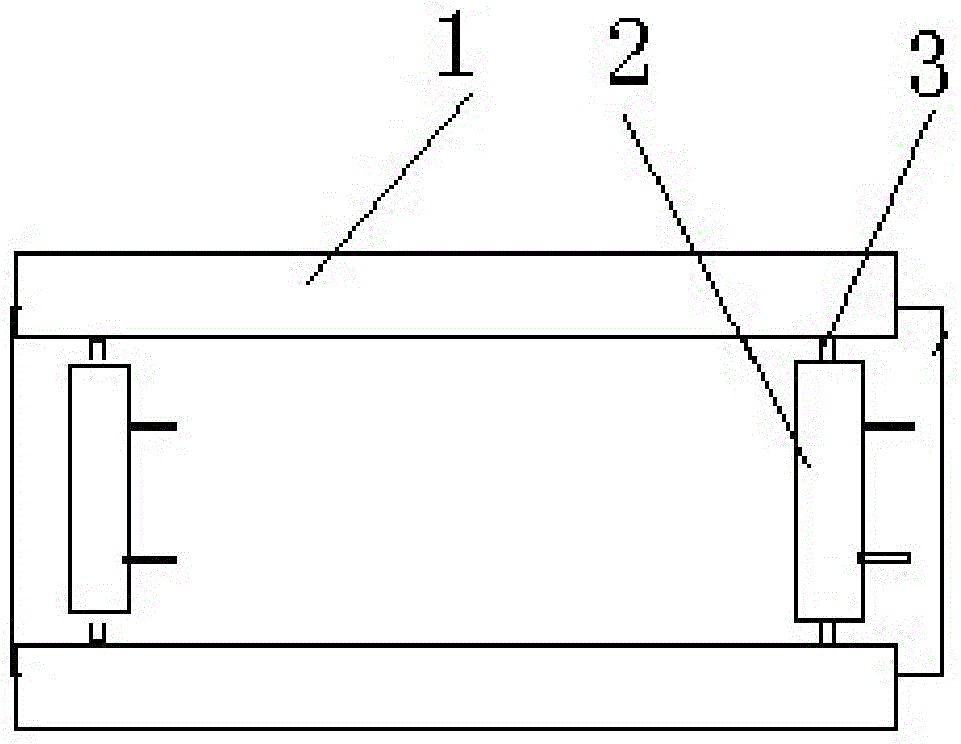

[0017] The method for the stainless steel cover in the large-diameter cylinder of the present invention, its preferred specific implementation is as follows figure 1 Shown:

[0018] Include steps:

[0019] First, the inner wall of the cylinder is bored, and a stainless steel sleeve is made according to the size of the inner wall of the cylinder after processing, and a triangular thread is processed on the inner wall of the cylinder;

[0020] Then, put the stainless steel sleeve in the cylinder body at normal temperature, carry out hot rolling on the stainless steel sleeve while heating, after the hot rolling is completed, lower it to normal temperature, and then carry out cold rolling on the stainless steel sleeve at normal temperature ;

[0021] Afterwards, the inner wall of the stainless steel sleeve is honed with a honing head.

[0022] The heating temperature of the stainless s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com