Additive and subtractive combined manufacturing device and method based on electron beam fuse

A manufacturing device and electron beam technology, applied in the direction of additive processing, etc., can solve the problems of poor practicability, achieve reliable molding quality, meet the requirements of dimensional accuracy and surface accuracy, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] device embodiment.

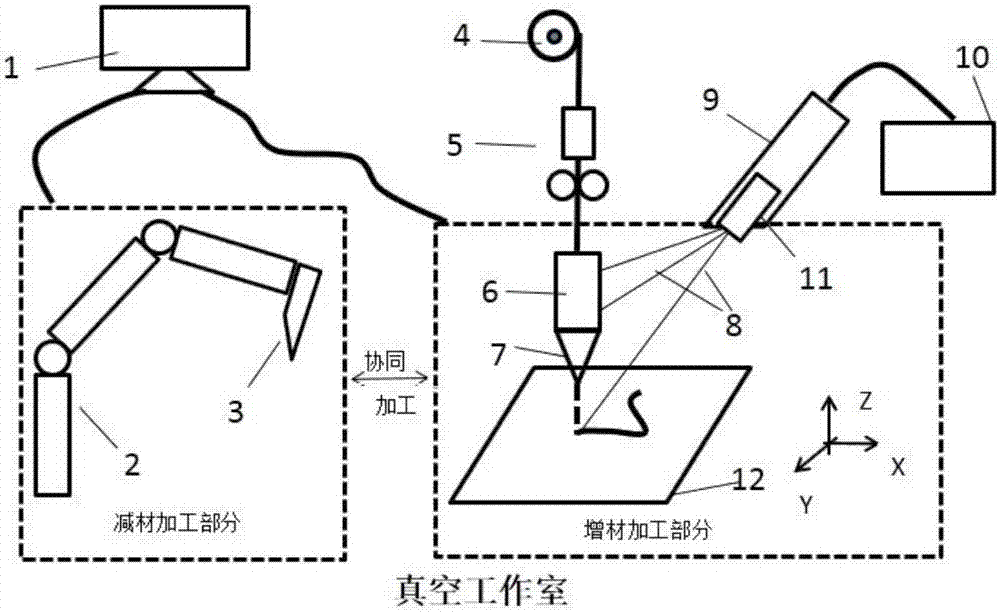

[0026] refer to figure 1 . The present invention is based on an electron beam fuse additive and subtractive composite manufacturing device, which includes an electron beam additive forming part, a material subtractive processing part and a host computer control system 1 working on the same motion platform. Wherein the motion platform 12 is arranged on the base, and can move in X, Y, Z directions and rotate around the Z axis. The vacuum device provides a vacuum working environment for the electron beam in the preparation stage (1×10 -3 Pa). The electron beam additive forming part includes an electron gun 9 (60kV / 8kW) that emits an electron beam 8; the electron gun deflection control system 11 controls the electron gun to emit the electron beam 8 according to the signal of the host computer control system 1 for deflection heating, so that the metal wire to be processed is melted into Liquid state, or by heating the spraying area, the spraying area...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com