Method for comprehensively utilizing copper-nickel sulfide ores and system thereof

A technology for sulfide ore and copper-nickel, applied in the field of non-ferrous metal metallurgy, can solve the problem of inability to effectively recover cobalt and precious metals, and achieve the effect of effective recovery, risk reduction and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

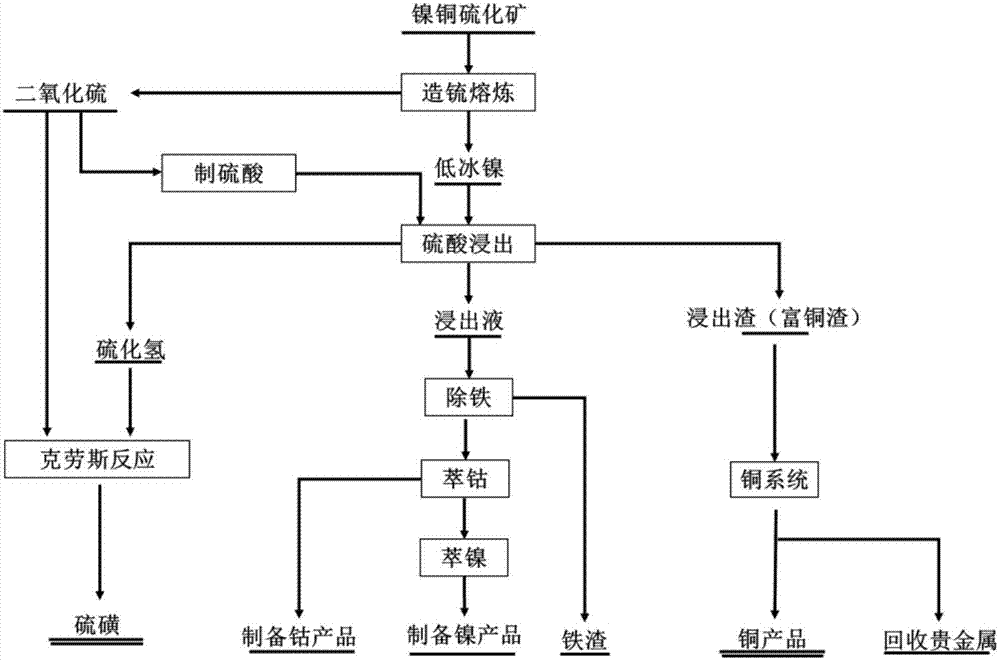

[0061] Such as figure 1 As shown, in this example, copper-nickel sulfide ore is matte-smelted to obtain low-matte nickel, and the content of main elements is: 20.21% Ni, 10.52% Cu, 37.44% Fe, 0.78% Co, and about 10g / t of precious metals.

[0062] Using this as raw material, leaching with 4mol / L sulfuric acid solution under normal pressure, the liquid-solid ratio is 10:1, the reaction temperature is 80°C, and the reaction is 0.5h. Iron, cobalt and nickel in low-nickel matte are leached into the solution, while almost all copper and precious metals are enriched in the leaching residue of cuprous sulfide, and the separation of copper and nickel and cobalt is realized. The copper content in the filtered solution is less than 0.005g / L, and the iron mainly exists in the form of ferrous ions, which can be directly oxidized by air without further reduction, while maintaining the pH of the solution at 3-5, so that iron can be removed by goethite precipitation , The obtained iron slag ...

Embodiment 2

[0065] Copper-nickel sulfide ore is smelted by matte making to obtain low nickel matte, the main element content: Ni 13.25%, Cu 8.32%, Fe38.44%, Co 0.64%.

[0066] Using this as raw material, leaching with 6mol / L sulfuric acid solution under normal pressure, the liquid-solid ratio is 2:1, the reaction temperature is 65°C, and the reaction is 1h. Iron, cobalt and nickel in low nickel matte are almost all leached into the solution, while copper is enriched in the slag, realizing the separation of copper and nickel and cobalt. The copper content in the filtered solution is less than 0.006g / L, and the iron mainly exists in the form of ferrous ions. Adjust the pH of the solution to 5-7, then place it in a closed autoclave, pass pure oxygen and heat up to 180°C, and iron with The hematite form is removed. The pH of the solution after iron removal is adjusted to 5, the cobalt is extracted with P507, and back-extracted with hydrochloric acid to obtain a cobalt chloride solution, whic...

Embodiment 3

[0069] Copper-nickel sulfide ore is smelted with matte to obtain low nickel matte, the main element content: Ni 16.55%, Cu 10.32%, Fe 33.44%, Co 0.34%, precious metal about 8.9 grams tons.

[0070]Using this as raw material, leaching with 1mol / L sulfuric acid solution under normal pressure, the liquid-solid ratio is 20:1, the reaction temperature is 25°C, and the reaction is 5h. Iron, cobalt and nickel in low-nickel matte are almost all leached into the solution, while copper and precious metals are enriched in the slag, realizing the separation of copper and nickel and cobalt. The copper content in the filtered solution is less than 0.008g / L, and the iron mainly exists in the form of divalent iron ions, without further reduction, it can be directly oxidized by passing 30%-60% oxygen-enriched air under normal pressure, and maintain the pH of the solution In 4-6, the iron is removed by precipitation of goethite, and the obtained iron slag is roasted into iron concentrate, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com