Heat-resistant, acid-resistant and ethanol-resistant wine brewing yeast and wine brewing leavening agent

A Saccharomyces cerevisiae and ethanol-resistant technology, which is applied in the field of wine making and microorganisms, can solve the problems that affect the smooth transfer production in autumn, the reduction of fermentation activity, and the rapid aging of yeast, so as to improve the quality and yield of wine, increase the acidity, and promote growth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

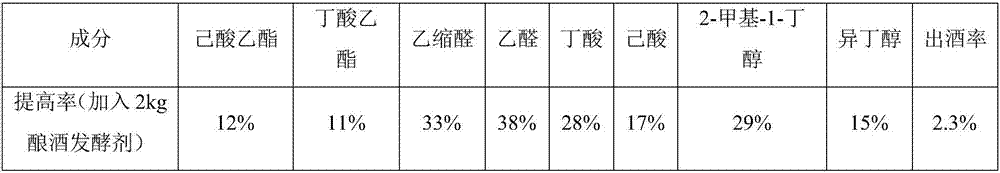

Embodiment 1

[0025] The present embodiment makes wine-making starter according to the following steps:

[0026] A. Preparation of seed solution: sterilize the glutinous rice saccharification solution at 121°C for 20 minutes, and use it as a culture medium;

[0027] According to the inoculum amount of 10%, Saccharomyces cerevisiae was inoculated into the culture medium, and cultured at 32°C for 20 hours to obtain the primary seed liquid of Saccharomyces cerevisiae;

[0028] According to the inoculum amount of 10%, the primary seed liquid of Saccharomyces cerevisiae was inoculated into the culture medium, and cultured at 32° C. for 20 hours to obtain the secondary seed liquid of Saccharomyces cerevisiae;

[0029] According to the inoculation amount of 10%, the secondary seed liquid of Saccharomyces cerevisiae was inoculated into the culture medium, and cultured at 32° C. for 20 hours to obtain the tertiary seed liquid of Saccharomyces cerevisiae.

[0030] B. Moisturizing material: get 80 pa...

Embodiment 2

[0039] The present embodiment makes wine-making starter according to the following steps:

[0040] A. Preparation of seed solution: sterilize the glutinous rice saccharification solution at 121°C for 20 minutes, and use it as a culture medium;

[0041] According to the inoculum amount of 10%, Saccharomyces cerevisiae was inoculated into the culture medium, and cultured at 32°C for 20 hours to obtain the primary seed liquid of Saccharomyces cerevisiae;

[0042] According to the inoculation amount of 10%, inoculate the primary seed liquid of S. medium, cultured at 32°C for 20 hours to obtain the third grade seed liquid of Saccharomyces cerevisiae.

[0043] B. Moisturizing material: get 100 parts of wheat bran, 15 parts of corn flour and 10 parts of rice husk, add moisturizing material after mixing to make the water content reach 48%, and obtain the mixed material;

[0044] C. Steaming material: under the conditions of steam pressure 0.1Mpa and temperature 105°C, mix the mixtur...

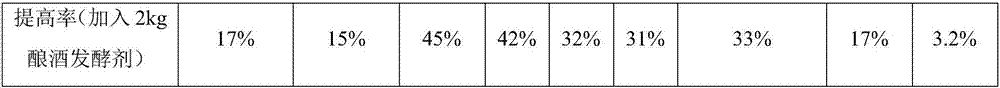

Embodiment 3

[0053] The present embodiment makes wine-making starter according to the following steps:

[0054] A. Preparation of seed solution: sterilize the glutinous rice saccharification solution at 121°C for 20 minutes, and use it as a culture medium;

[0055] According to the inoculum amount of 10%, Saccharomyces cerevisiae was inoculated into the culture medium, and cultured at 32°C for 20 hours to obtain the primary seed liquid of Saccharomyces cerevisiae;

[0056] According to the inoculum amount of 10%, the primary seed liquid of Saccharomyces cerevisiae was inoculated into the culture medium, and cultured at 32° C. for 20 hours to obtain the secondary seed liquid of Saccharomyces cerevisiae;

[0057] According to the inoculation amount of 10%, the secondary seed liquid of Saccharomyces cerevisiae was inoculated into the culture medium, and cultured at 32° C. for 20 hours to obtain the tertiary seed liquid of Saccharomyces cerevisiae.

[0058] B. Moisturizing material: get 90 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com