Temperature-resistant type high-permeable waterproof and moisture-penetration thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane, waterproof and moisture-permeable technology, applied in the field of elastomer and its preparation, can solve the problems of temperature resistance, mechanical properties and moisture permeability, high degradation difficulty, environmental pollution, etc., to achieve processing performance and waterproof and moisture permeability The effect of maintaining stability, stable preparation process, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

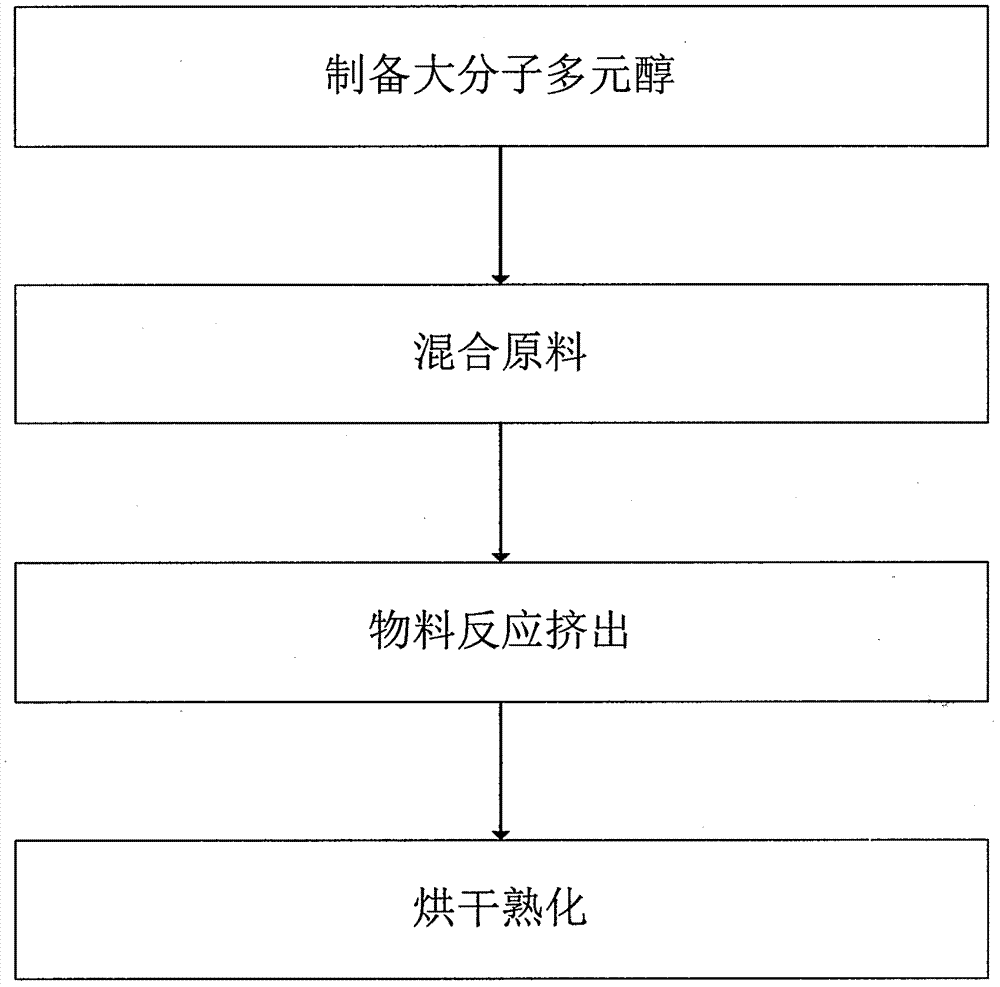

[0028] like figure 1 As shown, the preparation method of the temperature-resistant high-permeable waterproof and moisture-permeable thermoplastic polyurethane elastomer of the present invention comprises the following steps:

[0029] Step 1, preparing macromolecular polyols, mixing one or more of polyester polyols or polyether polyols with modified crystallizable soft segment hydrophilic polymers in a mass ratio of 1:0.1 to 1:1 , preparing raw material macromolecular polyols;

[0030] Step 2: Mix the raw materials, melt the macromolecular polyol at 80-120°C, and then vacuum dehydrate; place the diisocyanate and the small-molecule chain extender at 30-60°C and melt respectively, and weigh 30-100 parts by mass 1 part of macromolecular polyol, 5 to 50 parts of diisocyanate, 3 to 40 parts of small molecule chain extender, 0 to 20 parts of additives, control the isocyanate index to 0.95 to 1.05, hard segment content to 30% to 55%, and the raw materials pass through the flowmeter ...

Embodiment 1

[0036]The polytetrahydrofuran ether diol and the modified long-chain polyethylene glycol are uniformly mixed in a mass ratio of 1:0.1 to prepare a raw material macromolecular polyol. After melting 70 parts of macromolecular polyol at 80°C, vacuum dehydration; 30 parts of diphenylmethane diisocyanate and 18 parts of 1,4-butanediol were melted at 40°C respectively, and the raw materials were accurately metered into the twin-screw through a flow meter In the premixing unit, control the reaction time for 1 minute and the temperature at 180°C. The homogeneously mixed materials were injected into a twin-screw extruder for reactive extrusion. The reaction time was controlled to be 3 minutes, the rotational speed was 200 rpm, and the reaction temperature was 190°C. The thermoplastic polyurethane elastomer was obtained by underwater pelletizing. The obtained thermoplastic polyurethane elastomer was dried and aged in an oven at 100° C. for 8 hours to obtain the required temperature-resi...

Embodiment 2

[0038] The polyethylene adipate diol and the modified long-chain polyethylene glycol are uniformly mixed in a mass ratio of 1:0.3 to prepare a raw material macromolecular polyol. After melting 80 parts of macromolecular polyol at 90°C, vacuum dehydration; after mixing 7 parts of 1,2-propanediol and 13 parts of 1,3-propanediol, and 40 parts of toluene diisocyanate respectively at 50°C and melting, take 4 parts Hydrolysis stabilizer, the raw material is accurately metered into the twin-screw premixing unit through a flow meter, and the reaction time is controlled for 2 minutes and the temperature is 150°C. The homogeneously mixed material was injected into a twin-screw extruder for reaction extrusion, the reaction time was controlled to be 2 minutes, the rotation speed was 300 rpm, and the reaction temperature was 200°C, and thermoplastic polyurethane elastomer was obtained by underwater pelletizing. The obtained thermoplastic polyurethane elastomer was dried and matured in an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com