Method of continuously preparing high-quality graphene in a large scale

A graphene, high-quality technology, applied in the field of continuous large-scale preparation of high-quality graphene, can solve the problems of many graphene defects, long production cycle, high cost, etc., and achieve simple preparation process, complete sheet structure, and effective exfoliation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

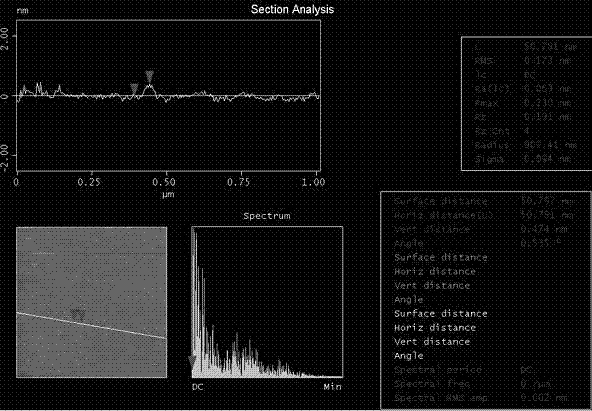

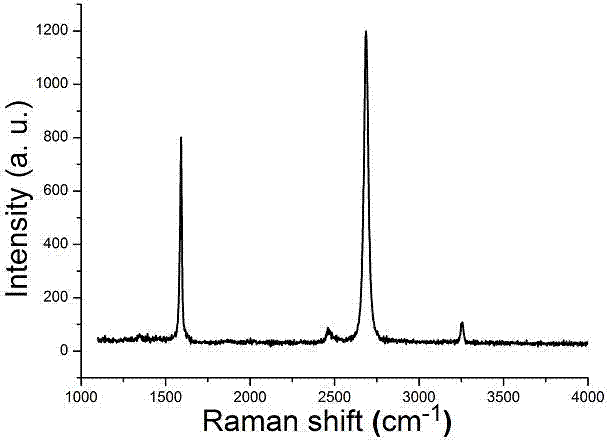

Image

Examples

Embodiment 1

[0040] Embodiment 1 A method for continuously preparing high-quality graphene on a large scale, comprising the following steps:

[0041] (1) Mix a total of 1000 g of the carbon source - flake graphite with a particle size of 20 μm and the surface isolation synergistic stabilizer - polyacrylamide at a volume ratio of 100:1 to obtain a mixture.

[0042] (2) Disperse the mixture in 6000mL of liquid medium—a mixture of water and ethanol (molar ratio 1:1), and place it in a ball mill at a temperature of 60°C for grinding and peeling. After 5 hours, a graphene dispersion is obtained, which can be Apply directly to liquid systems.

[0043] Wherein: the ball mill refers to a vertical sand mill, and the peeling speed is 4000rpm. The internal structure of the ball mill is a rod tip type, and the built-in grinding ball refers to an alumina ball with a diameter of 0.05mm~1mm.

[0044] (3) For environments that require graphene powder, the graphene dispersion can be spray-dried to obtain...

Embodiment 2

[0046] Embodiment 2 A method for continuously preparing high-quality graphene on a large scale, comprising the following steps:

[0047] (1) Mix 800 g of carbon source - dense crystalline graphite with a particle size of 1 mm and surface isolation synergistic stabilizer - gum arabic and sucrose (volume ratio 1:1) in a volume ratio of 1:1 to obtain a mixture.

[0048] (2) Disperse the mixture in 5000mL of liquid medium—water, and place it in a ball mill at a temperature of 40°C for grinding and peeling. After 3 hours, a graphene dispersion is obtained, which can be directly applied to a liquid system.

[0049] Wherein: the ball mill refers to a horizontal sand mill, and the peeling speed is 2000rpm. The internal structure of the ball mill is disc type, and the built-in grinding balls are zirconia balls with a diameter of 0.05mm~1mm.

[0050] (3) For environments that require graphene powder, the graphene dispersion can be dried under normal pressure to obtain graphene powder. ...

Embodiment 3

[0052] Embodiment 3 A method for continuously preparing high-quality graphene on a large scale, comprising the following steps:

[0053] (1) Mix 1000 g of carbon source—cryptocrystalline graphite with a particle size of 50 μm and surface isolation synergistic stabilizer—hydroxyethyl cellulose in a volume ratio of 30:1 to obtain a mixture.

[0054] (2) Disperse the mixture in 3000mL of liquid medium—water, and put it in a ball mill for grinding and peeling at a temperature of 50°C. After 0.5h, a graphene dispersion is obtained, which can be directly applied to a liquid system.

[0055] Wherein: the ball mill refers to a horizontal sand mill, and the peeling speed is 4000rpm. The internal structure of the ball mill is a combination of pins and discs, and the built-in grinding balls are zirconium silicate balls with a diameter of 0.05mm~10.mm.

[0056] (3) For environments that require graphene powder, the graphene dispersion is dried under reduced pressure to obtain graphene po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com