Single-phase multiferroic M-type strontium ferrite ceramic and preparation method thereof

A strontium ferrite and multiferroic technology, which is applied in the field of single-phase multiferroic M-type strontium ferrite ceramic materials and their preparation, can solve the problems of difficulty in reaching saturation of ferroelectricity, large leakage current, etc. Good ferroelectricity and ferromagnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

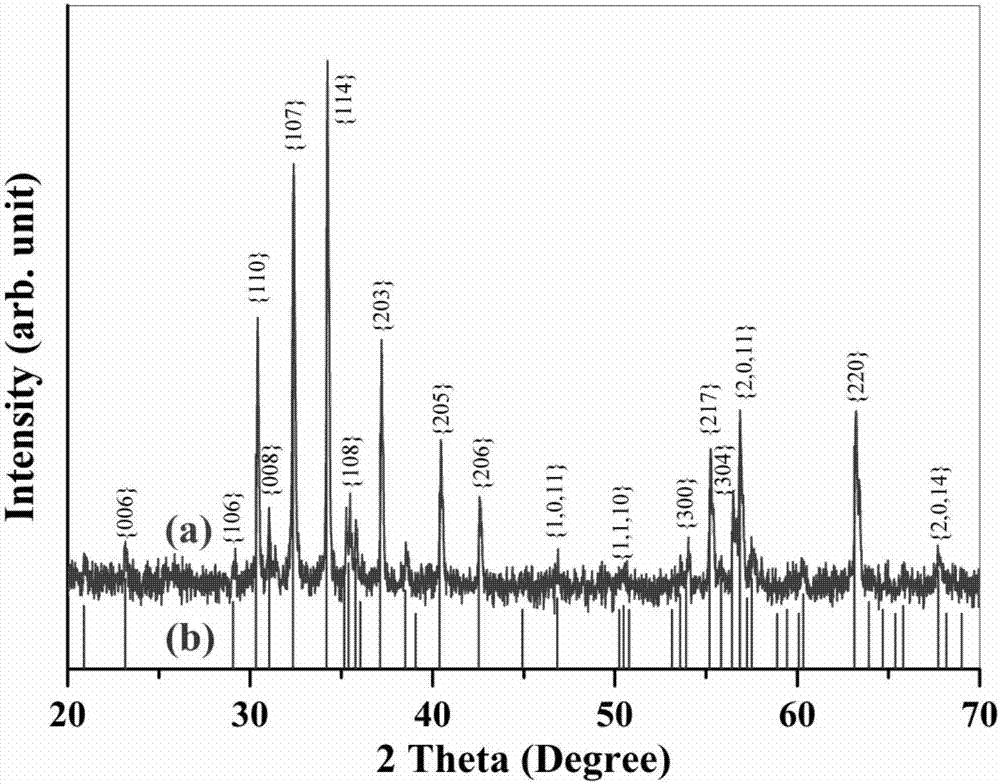

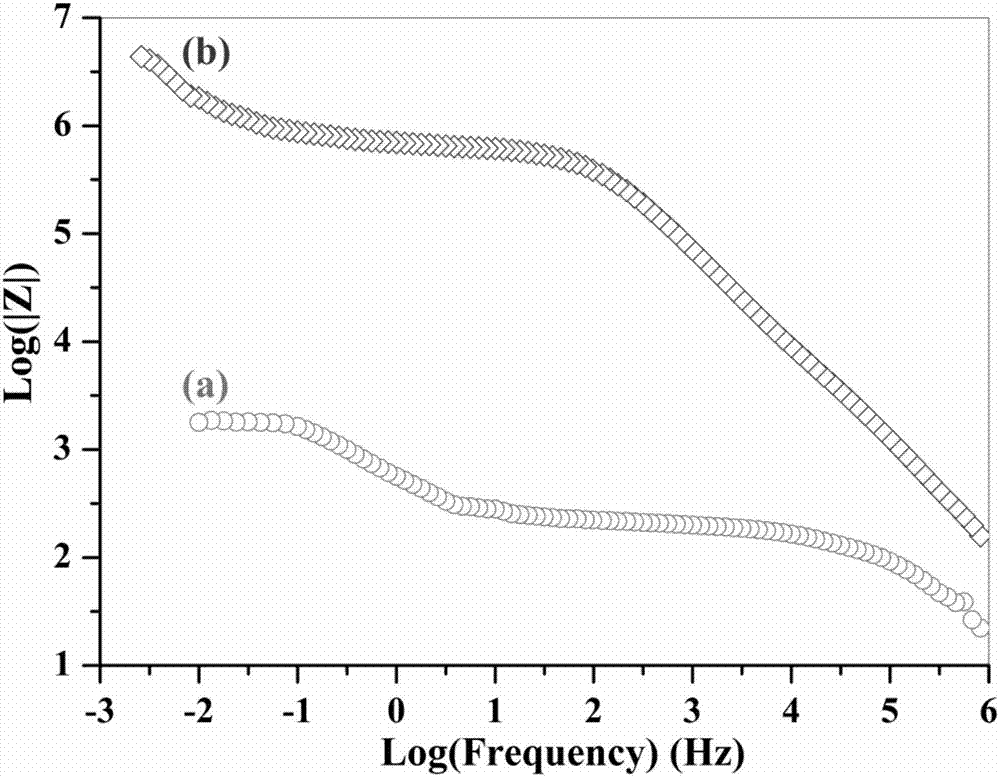

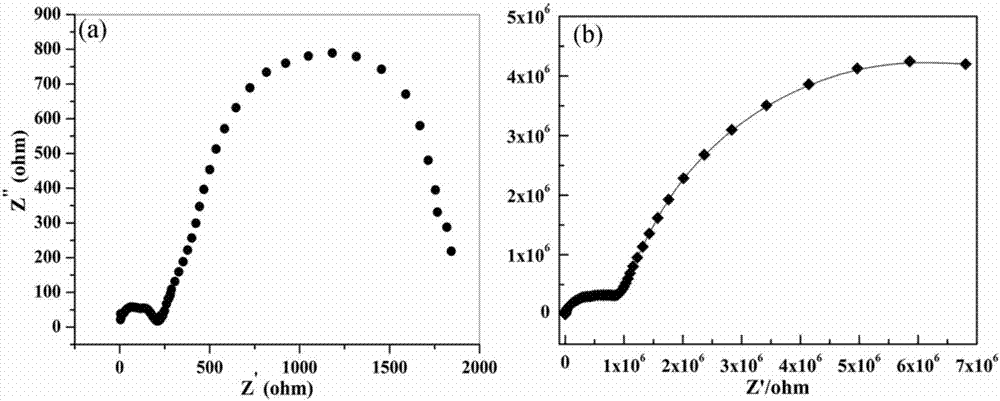

[0033] According to the Sr / Fe ratio of 1:9.5, weigh strontium acetate 0.30925g and iron acetylacetonate 5.0460 respectively and dissolve them in 15ml glycerin, 120ml alcohol and 50ml acetone, and weigh polyethylene glycol (molecular weight: 20000) 1g first. Dissolve in 5ml of deionized water and add 45ml of ammonia water for later use. At the same time, mix the obtained iron precursor solution at 70°C for 6 to 8 hours to prevent the hydrolysis of iron acetylacetonate; then add the prepared strontium precursor solution and fully mix it at 70°C for a certain period of time; finally, the configured A good mixture of polyethylene glycol and ammonia water is poured into the precursor mixture of strontium and iron and fully reacted at 70°C for more than 24 hours. Centrifuge the obtained suspension solution, pour off the supernatant, and dry the centrifuged precipitate in an oven at 90°C, put the dried precipitate into a corundum crucible, and raise the temperature from room temperat...

Embodiment 2

[0037] According to the Sr / Fe ratio of 1:9.5, weigh strontium acetate 0.30925g and iron acetylacetonate 5.0460 respectively and dissolve them in 15ml of glycerin, 120ml of alcohol and 50ml of acetone, and weigh 1g of polyethylene glycol (molecular weight: 20000) First dissolve in 5ml deionized water and then add 45ml ammonia water for later use. At the same time, mix the obtained iron precursor solution at 70°C for 6 to 8 hours to prevent the hydrolysis of iron acetylacetonate; then add the configured strontium precursor solution and mix it at 70°C for a certain period of time; finally, the configured The mixture of polyethylene glycol and ammonia water is poured into the precursor mixture of strontium and iron and fully reacted at 70°C for more than 24 hours. Centrifuge the obtained suspension solution, pour off the supernatant, and dry the centrifuged precipitate in an oven at 90°C, put the dried precipitate into a corundum crucible, and raise the temperature from room tempe...

Embodiment 3

[0040]According to the Sr / Fe ratio of 1:9.5, weigh strontium acetate 0.30925g and iron acetylacetonate 5.0460 respectively and dissolve them in 15ml glycerin, 120ml alcohol and 50ml acetone, and weigh polyethylene glycol (molecular weight: 20000) 1g first. Dissolve in 5ml of deionized water and add 45ml of ammonia water for later use. At the same time, mix the obtained iron precursor solution at 70°C for 6 to 8 hours to prevent the hydrolysis of iron acetylacetonate; then add the prepared strontium precursor solution and fully mix it at 70°C for a certain period of time; finally, the configured A good mixture of polyethylene glycol and ammonia water is poured into the precursor mixture of strontium and iron and fully reacted at 70°C for more than 24 hours. Centrifuge the obtained suspension solution, pour off the supernatant, and dry the centrifuged precipitate in an oven at 90°C, put the dried precipitate into a corundum crucible, and raise the temperature from room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Residual magnetization | aaaaa | aaaaa |

| Remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com