Vacuum insulated panel with excellent fireproof performance and production method thereof

A vacuum insulation panel, an excellent technology, applied in fire protection, chemical instruments and methods, insulation improvement, etc., can solve the problems of high equipment requirements, non-environmental protection, high production cost, etc. good burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

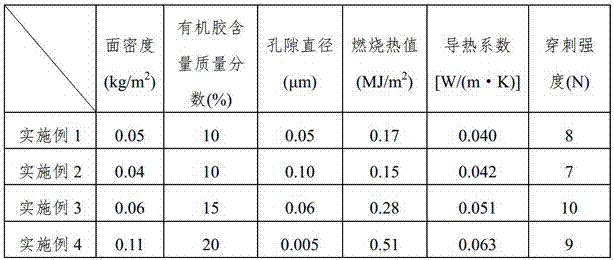

[0044] A vacuum insulation panel with excellent fire resistance, comprising a core board and a high-resistance gas film bag 3, the high-resistance gas film bag 3 is packaged outside the core board, the core board includes a core material 1 and a cladding material 2, and the cladding material 2 is packaged On the outside of the core material 1, the cladding material 2 is an inorganic cotton felt, and the surface density of the inorganic cotton felt is 50g / m 2 , the organic gum content mass fraction is 10%, and the combustion heat value is 0.17MJ / m 2 ; The total heat of combustion of the high resistance gas film bag 3 is 3.05 MJ / m 2 .

[0045] The core material 1 includes 20 parts of precipitated silicon dioxide, 50 parts of fumed silicon dioxide, 10 parts of airgel, 8 parts of inorganic fiber and 0.7 parts of vacuum stabilizer in parts by weight.

[0046] The inorganic felt is a glass fiber felt made of ultrafine glass wool.

[0047] The high-barrier gas film bag 3 is compos...

Embodiment 2

[0054] A vacuum insulation panel with excellent fireproof performance, comprising a core board and a high-resistance gas film bag, the high-resistance gas film bag is packaged outside the core board, the core board includes a core material and a cladding material, and the cladding material is packaged outside the core material. The covering material is an inorganic cotton felt, and the surface density of the inorganic cotton felt is 40g / m 2 , the organic gum content mass fraction is 10%, and the combustion heat value is 0.15MJ / m 2 ; The total heat of combustion value of the high resistance gas film bag is 2.94 MJ / m 2 .

[0055] The core material comprises 20 parts of microsilica fume, 50 parts of precipitated silicon dioxide, 10 parts of fumed silicon dioxide, 28 parts of airgel, 5 parts of inorganic fiber and 4.2 parts of vacuum stabilizer in parts by weight.

[0056] The inorganic felt is aluminum silicate fiber felt.

[0057] The high-barrier gas film bag is composed of ...

Embodiment 3

[0064] A vacuum insulation panel with excellent fireproof performance, comprising a core board and a high-resistance gas film bag, the high-resistance gas film bag is packaged outside the core board, the core board includes a core material and a cladding material, and the cladding material is packaged outside the core material. The covering material is an inorganic cotton felt, and the surface density of the inorganic cotton felt is 60g / m 2 , the organic gum content mass fraction is 15%, and the combustion heat value is 0.28MJ / m 2 ; The total heat of combustion of the high resistance gas film bag is 3.27MJ / m 2 .

[0065] The core material comprises 40 parts of precipitated silicon dioxide, 20 parts of fumed silicon dioxide, 25 parts of airgel, 5 parts of inorganic fiber and 2 parts of vacuum stabilizer in parts by weight.

[0066] The inorganic felt is calcium carbonate fiber felt.

[0067] The high-barrier gas film bag is composed of inorganic fiber film, glass fiber cloth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com