Polycrystalline diamond tool for machining excircles and inner holes of copper materials of all types

A polycrystalline diamond and inner hole technology, which is used in the cutting tools, manufacturing tools, metal processing equipment and other directions of lathes, can solve problems such as harm to the human body, and achieve the effects of clear processing lines, reduced manufacturing costs, and high smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

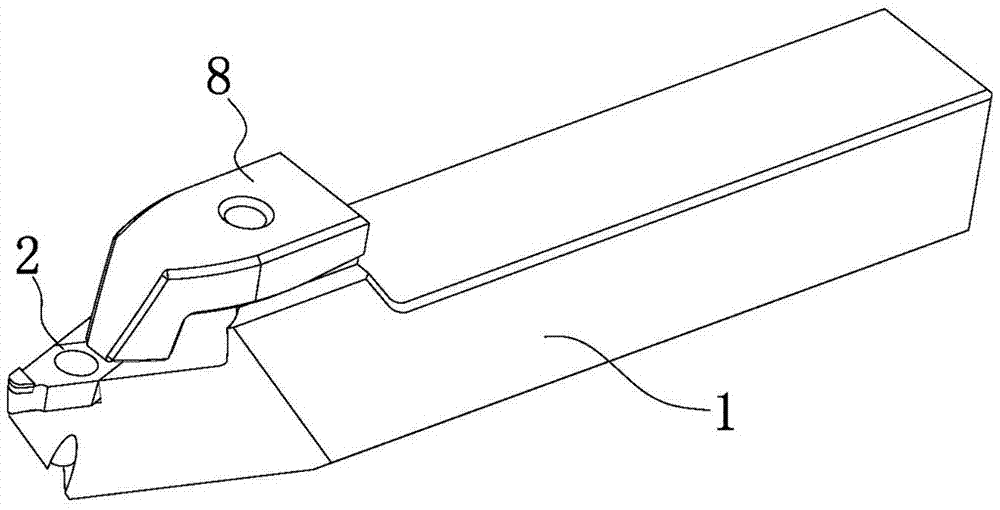

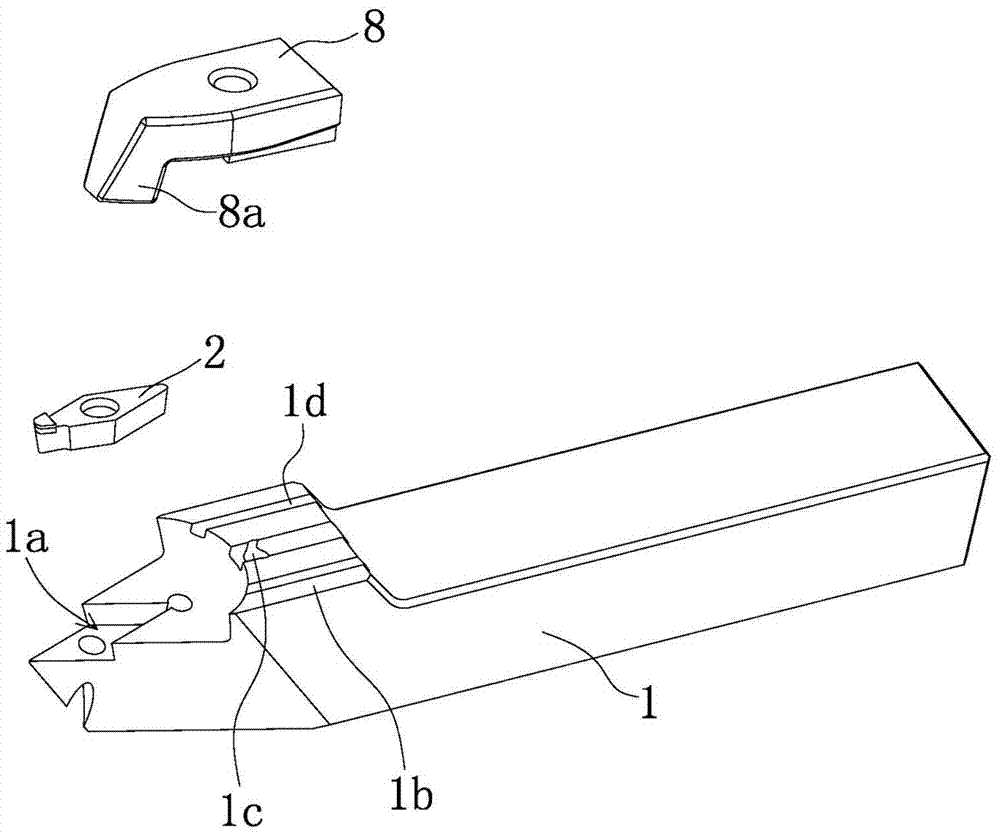

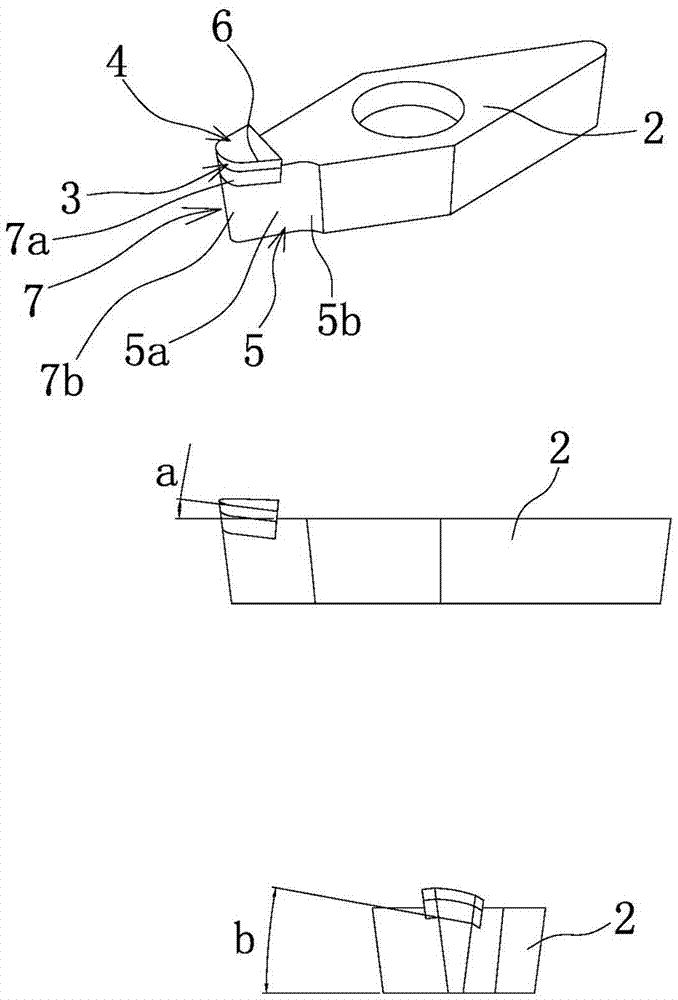

[0022] Such as figure 1 , figure 2 and image 3 As shown, the polycrystalline diamond tool used for machining the outer circle and inner hole of various copper materials includes a cutter body 1 and a blade 2 installed on the cutter body 1. The cutting edge of the blade 2 is a large radius 3, and a large radius 3 The radius is 1.0mm-1.4mm, and the blade 2 has a double compound rake angle 4 so that the rake angle a of the blade face and the horizontal plane is 2°-10° and the left rake angle b of the blade face and the horizontal plane is 5°-15°. In the example, the radius of the large fillet 3 is 1.2 mm, the forward inclination a is 5°, and the left inclination b is 10°. The side of the insert 2 is provided with a later...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com