Cycloolefin-based film

A cycloolefin-based and cycloolefin technology, applied in the field of cycloolefin-based films, can solve the problems of button durability, difficulty in filming, and uneven display, and achieve excellent button durability, high adhesion, and reduced display unevenness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

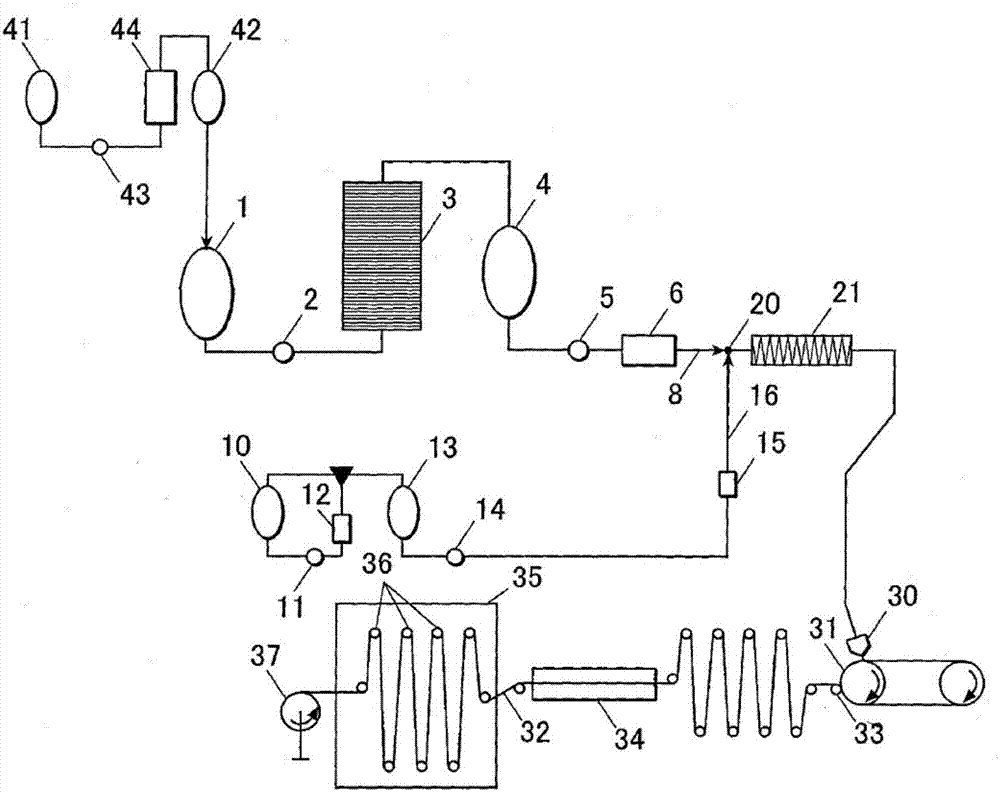

Method used

Image

Examples

Embodiment 1

[0338]

[0339] (Synthesis of cycloolefin-based polymer 1)

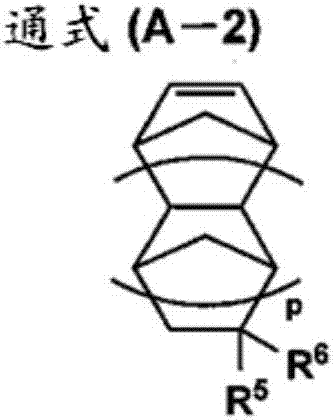

[0340] 22100 parts of the exemplary compound of the cycloolefin monomer (general formula A-2), 3.6 parts of 1-hexene as a molecular weight regulator, and 200 parts of toluene were put into a nitrogen-substituted reaction vessel, and heated to 80°C. Add triethylaluminum ((C) as polymerization catalyst therein 2 h 5 ) 3 Al) 0.17 parts of toluene solution of 1.5 mol / L and WCl 6 1.0 parts of the solution (concentration: 0.05 mol / L) was heated and stirred at 80° C. for 3 hours to perform a ring-opening polymerization reaction to obtain a polymer solution. The polymerization conversion rate in this polymerization reaction was 98%. Among them, the above WCl 6 The solution is tungsten hexachloride (WCl 6 ) modified, and the molar ratio of tert-butanol to methanol to tungsten is 0.35:0.3:1 WCl 6 solution.

[0341] 4000 parts of the resulting polymer solution was put into an autoclave, and 0.48 parts of RuHCl(CO)[P(C ...

Embodiment 2

[0406]

[0407] In production of the cycloolefin-based film 101 , the cycloolefin-based film 201 was produced in the same manner except that the main dope 1 was changed to the following main dope 2 .

[0408]

[0409]

[0410]

[0411] In the preparation of the cycloolefin-based film 201, as described in Table 2, as a solvent for synthesizing the cycloolefin-based resin, in addition to toluene, which is an aromatic solvent, xylene and styrene were used. In addition to methane, chloroform and 1,2-dichloroethane were also used as halide-based solvents, and various solvents listed in Table 2 were used in equivalent amounts as non-aromatic solvents. The cycloolefin-based films 202 to 218 are prepared in a precise manner.

[0412] Table 2 shows the results of (1) key durability test and (2) evaluation of display unevenness in Example 1 using the produced cycloolefin-based films 201 to 218 .

[0413] 【Table 2】

[0414]

[0415] As can be seen from Table 2, the cycloole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com