Vanadium manganese sodium phosphate @ 3D porous graphene composite material, preparation method thereof, and applications of vanadium manganese sodium phosphate @ 3D porous graphene composite material in sodium-ion batteries

A technology of sodium vanadium manganese phosphate and porous graphene, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems affecting rate performance and capacity, poor electronic conductivity of vanadium manganese sodium phosphate, etc., and improve load stability. , Improve the crystal structure, the effect of good load stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Firstly, 0.005 mol of vanadyl acetylacetonate, 0.005 mol of manganese acetate tetrahydrate, 0.015 mol of ammonium dihydrogen phosphate, and 0.02 mol of sodium acetate were dissolved in 40 mL of deionized water and stirred thoroughly to obtain a clear solution. Then 0.106 g (8% of the theoretical product mass) of graphene oxide was added to the solution, and after ultrasonic treatment for 30 min, it was stirred at room temperature for 12 h. Then the solution was transferred to a 60mL reactor and reacted at 180°C for 10h. The hydrogel precursor is obtained, and the aerogel is obtained through freeze-drying. The precursor was sintered at 750 °C for 9 h in a tube furnace under an argon atmosphere to obtain a sheet-like structure of sodium vanadium manganese phosphate@3D porous graphene composite.

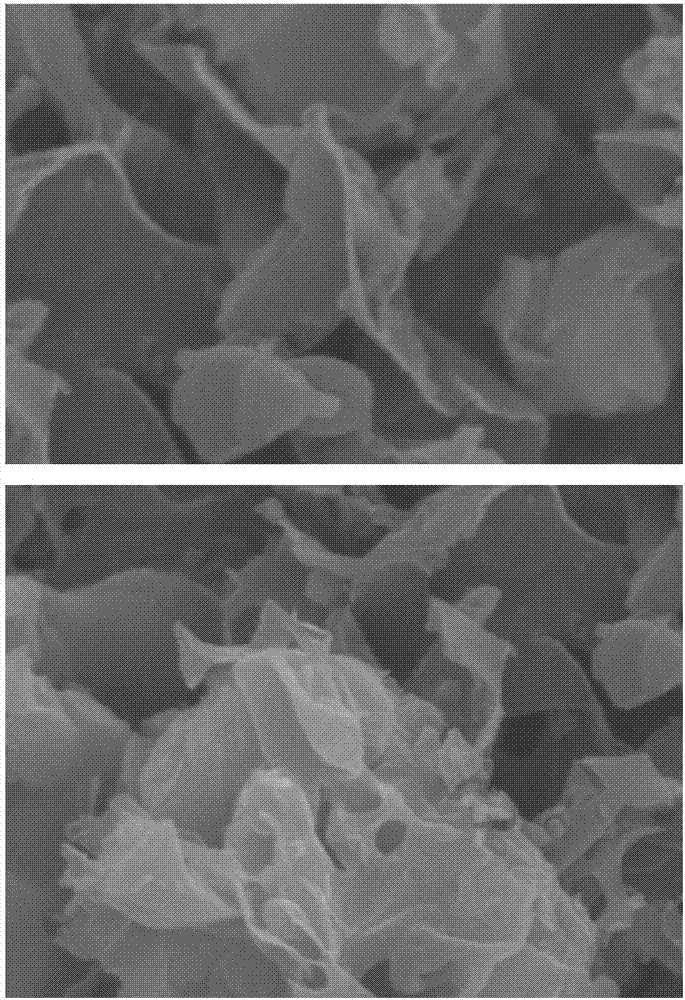

[0045] See figure 1 . The scanning electron microscope (SEM) image of the prepared sheet-like structure sodium vanadium manganese phosphate@3D porous graphene composite materi...

Embodiment 2

[0048] Firstly, 0.005 mol of vanadyl acetylacetonate, 0.005 mol of manganese acetate tetrahydrate, 0.015 mol of ammonium dihydrogen phosphate, and 0.02 mol of sodium acetate were dissolved in 40 mL of deionized water and stirred thoroughly to obtain a clear solution. Then 0.158 g (12% of the theoretical product mass) of graphene oxide was added to the solution, and after ultrasonic treatment for 30 min, it was stirred at room temperature for 12 h. Then the solution was transferred to a 60mL reactor and reacted at 180°C for 10h. The hydrogel precursor is obtained, and the aerogel is obtained through freeze-drying. The precursor was sintered at 750 °C for 9 h in a tube furnace under an argon atmosphere to obtain a sheet-like structure of sodium vanadium manganese phosphate@3D porous graphene composite.

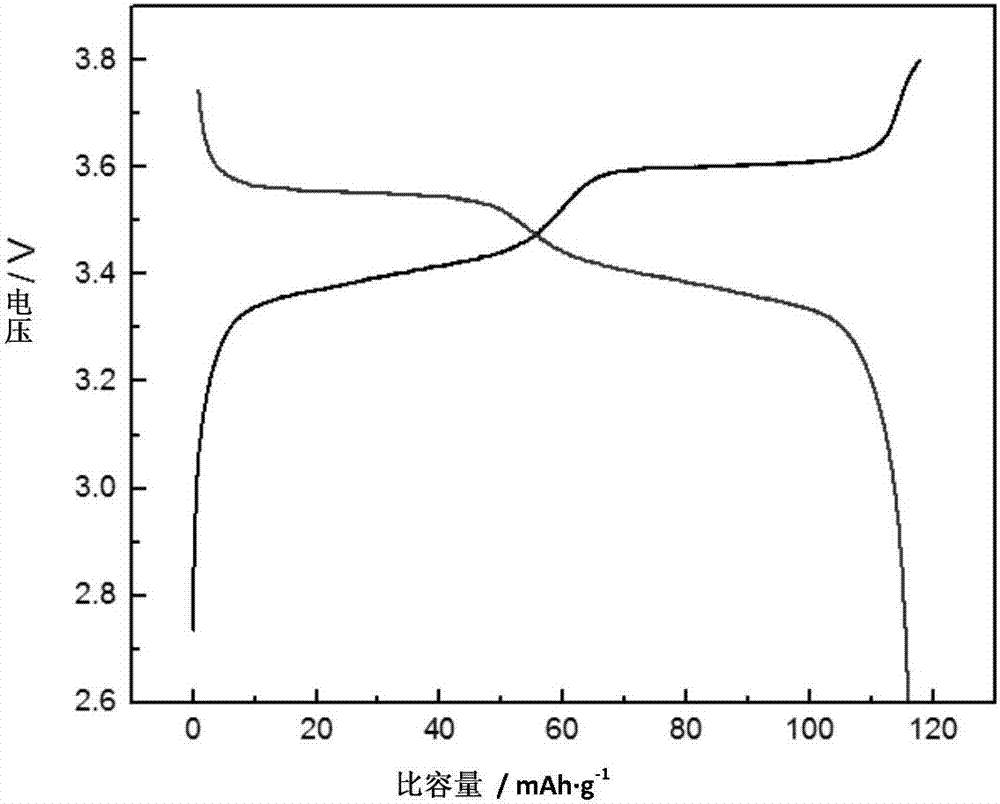

[0049] The sodium ion battery composite positive electrode material prepared in this example and the sodium sheet were assembled into a button battery. At a rate of 0.5C, the s...

Embodiment 3

[0051] Firstly, 0.005 mol of vanadyl acetylacetonate, 0.005 mol of manganese acetate tetrahydrate, 0.015 mol of ammonium dihydrogen phosphate, and 0.02 mol of sodium acetate were dissolved in 40 mL of deionized water and stirred thoroughly to obtain a clear solution. Then 0.040 g (3% of the theoretical product mass) of graphene oxide was added to the solution, and after ultrasonic treatment for 30 min, it was stirred at room temperature for 12 h. Then the solution was transferred to a 60mL reactor and reacted at 180°C for 10h. The hydrogel precursor is obtained, and the aerogel is obtained through freeze-drying. The precursor was sintered at 750 °C for 9 h in a tube furnace under an argon atmosphere to obtain a sheet-like structure of sodium vanadium manganese phosphate@3D porous graphene composite.

[0052] The sodium ion battery composite cathode material prepared in this example and the sodium sheet were assembled into a button battery at a rate of 0.5C, and after 50 cycle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com