A kind of composite hollow microsphere and its preparation method and application

A technology of hollow microspheres and hollow spheres, which is applied in the field of petroleum exploration, can solve the problems of being unable to withstand high pressure or grinding construction environment, difficult to control the density of drilling fluid, and large consumption of materials, so as to achieve fewer process steps and reaction influencing factors, The effect of small density change and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

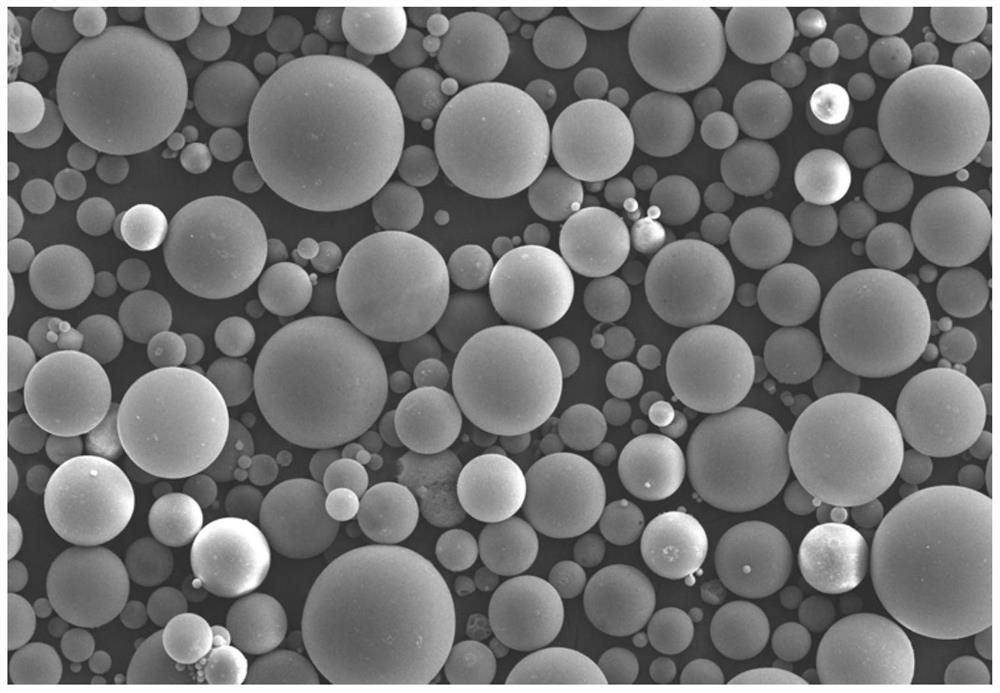

[0075] Preparation method of composite hollow microspheres

[0076] Pretreatment of inorganic hollow spheres: Weigh 1.0kg of commercially available borosilicate glass hollow microspheres (density 0.45g / cm 3 , pressure resistance 40MPa, average particle size 80μm), add 3.5 liters of ethanol at 25 ° C, and stir for 1.5 hours under the condition of 150r / min. The ethanol was removed by filtration, and the cleaned hollow glass microspheres were placed in a vacuum drying oven at 80° C. for 4 hours for use.

[0077] Surface coupling treatment of inorganic hollow spheres: using absolute ethanol as a solvent, prepare 2kg of a 10wt% KH-550 silane coupling agent solution, adjust the pH of the solution to 4 with glacial acetic acid, and slowly add 0.4kg of the above-mentioned solution while stirring. After cleaning and drying the hollow glass microspheres, the stirring speed was 150r / min, and then the temperature was raised to 55°C for reaction for 2h. After the reaction is completed, fil...

Embodiment 2

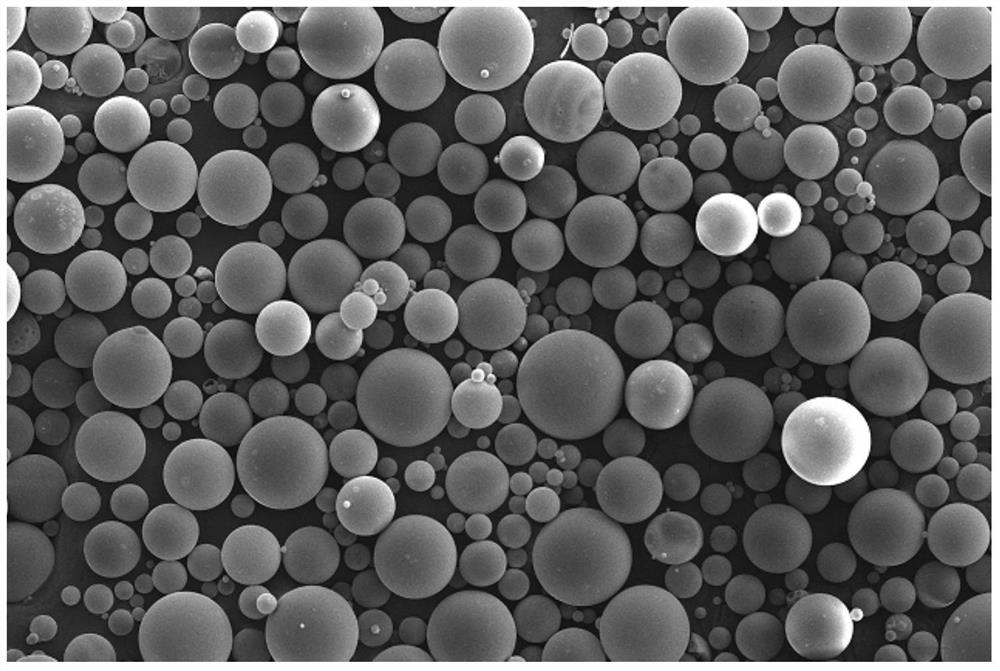

[0092] Preparation method of composite hollow microspheres

[0093] Pretreatment of inorganic hollow spheres: Weigh 0.8kg of commercially available hollow borosilicate glass microspheres (density 0.40g / cm 3 , pressure resistance 28MPa, average particle size 89μm), add 3 liters of ethanol at 25°C, and stir for 1 hour under the condition of 150r / min. The ethanol was removed by filtration, and the cleaned hollow glass microspheres were placed in a vacuum drying oven at 80° C. to dry for 2 hours for use.

[0094] Surface coupling treatment of inorganic hollow spheres: use absolute ethanol as solvent, prepare 3kg of 10wt% KH-560 silane coupling agent solution, adjust the pH of the solution to 4 with glacial acetic acid, and slowly add 0.5kg of the above-mentioned solution while stirring The surface-cleaned hollow glass microspheres were stirred at a speed of 120 r / min, and then heated to 55° C. for reaction for 2.5 hours. After the reaction is completed, filter the filter cake, w...

Embodiment 3

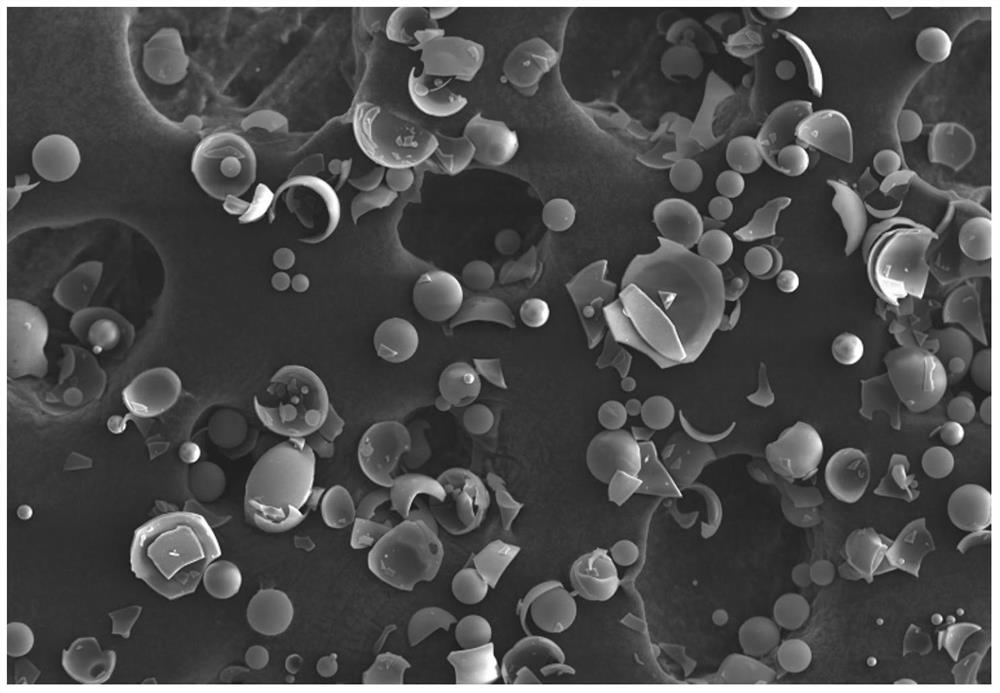

[0104] Preparation method of composite hollow microspheres

[0105] Pretreatment of inorganic hollow spheres: Weigh 1.0kg of commercially available silica hollow microspheres (density 0.5g / cm 3 , pressure resistance 40MPa, average particle size 90μm), add 3.5 liters of ethanol at 25 ° C, and stir for 1.5 hours under the condition of 150r / min. The ethanol was removed by filtration, and the cleaned hollow glass microspheres were placed in a vacuum drying oven at 80° C. for 4 hours for use.

[0106] The preparation of organic prepolymer: in the jacketed reaction kettle equipped with agitator, thermometer and condenser, add 7.29kg of 37wt% formaldehyde solution, adjust the pH value to 8 with ammonia, add 4.23kg of benzoic melamine, stir to After all dissolved, slowly heat up, react at a constant temperature of 85° C. for 3 hours, cool to room temperature, add 1.8 kg of deionized water and stir evenly to obtain a benzo-substituted melamine formaldehyde prepolymer for use. The sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com