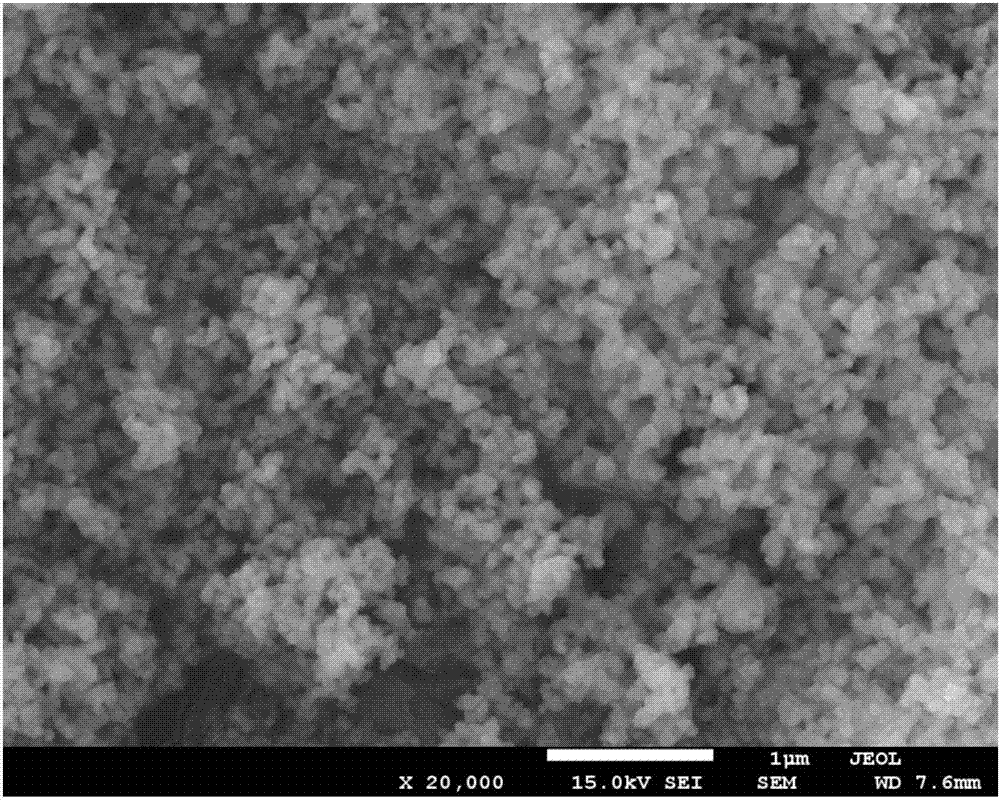

Preparation method of loose zirconium hydroxide or zirconium oxide nano powder

A technology of nano-powder and zirconium hydroxide, which is applied in zirconia, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of increasing costs, achieve excellent performance, easy to filter and wash, and streamline the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the zirconia-containing nano-loose powder of the present invention specifically comprises the following steps:

[0041]1) Precipitant A solution with a concentration of 0.05-4mol / L is prepared. The precipitant A solution contains dissolved carbonate, ammonium chloride, ammonium bicarbonate, calcium hydroxide, potassium hydroxide, sodium hydroxide, and One or more, while the precipitant A solution contains alcohols, wherein the alcohols have no more than 4 carbon atoms. The pH value of the precipitant A solution is adjusted to 3-13, the pH value is preferably in the range of 4-12, and the pH value is more preferably in the range of 5-11.

[0042] 2) Prepare a precipitant B solution with a concentration of 0.1-8mol / L, and the precipitant B solution contains one or more of dissolved sodium hydroxide, potassium hydroxide, calcium hydroxide, and ammonia water.

[0043] 3) In the solution containing zirconium salt, the concentration of zirconium ion...

Embodiment 1

[0048] Prepare a zirconium oxychloride and yttrium chloride mixed raw material solution with a concentration of 0.4mol / L. In this solution, the molar ratio of Zr ions to doped Y ions is 92:8. In the zirconium-containing raw material solution, ethanol and water The volume ratio of ammonium bicarbonate and ammonia water is 1:4; the mixed solution A of ammonium bicarbonate and ammonia water with a preparation concentration of 0.07mol / L (in the mixed solution, the mol ratio of ammonium bicarbonate and ammonia water is 1:1, and the volume ratio of ethanol and water is 1 :5), adjust the pH value to 7; the preparation concentration is the sodium hydroxide solution B of 3mol / L, and the pH value is 14. In the case of continuous stirring, first add the mixed raw material solution containing zirconium salt to the mixed solution A previously placed in the reactor at an initial flow rate of 0.01L / min; after adding for a period of time, the solution in the reactor changes from turbid to clea...

Embodiment 2

[0051] Prepare a zirconium oxychloride and yttrium chloride mixed raw material solution with a concentration of 0.8mol / L. In this solution, the molar ratio of Zr ions to doped Y ions is 92:8. In the zirconium-containing raw material solution, ethanol and water The volume ratio is 2:5; the preparation concentration is 0.1mol / L sodium carbonate and ammonia mixed solution A (in the mixed solution, the mol ratio of sodium carbonate and ammonia is 1:1), adjust the pH value to 8; the prepared concentration is 5mol / L sodium hydroxide solution B, the pH value is 14. Under the condition of continuous stirring, first add the mixed raw material solution containing zirconium salt to the mixed solution A previously placed in the reactor at an initial flow rate of 0.05L / min; after adding for a period of time, the solution in the reactor changes from turbid to clear, At the same time, solution B is added to the mixed solution of zirconium salt mixed raw material solution and mixed solution A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com