Preparation method of nano ato powder

A powder and nanotechnology, applied in the field of nanomaterials preparation, can solve the problems of high resistivity, large particle size of antimony-doped nano-tin dioxide powder, uneven distribution of dopants, etc., and achieve small resistivity and particle size. The effect of small diameter distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of nanometer ATO powder, comprising:

[0023] Step 1, take by weighing antimony chloride and tin chloride according to the molar ratio of 1:10, dissolve with dehydrated alcohol, and add ethylene glycol, obtain mixed solution; Wherein, the use amount of dehydrated alcohol is the quality of tin chloride 20 times, the amount of ethylene glycol added is 100 times the mass of tin chloride;

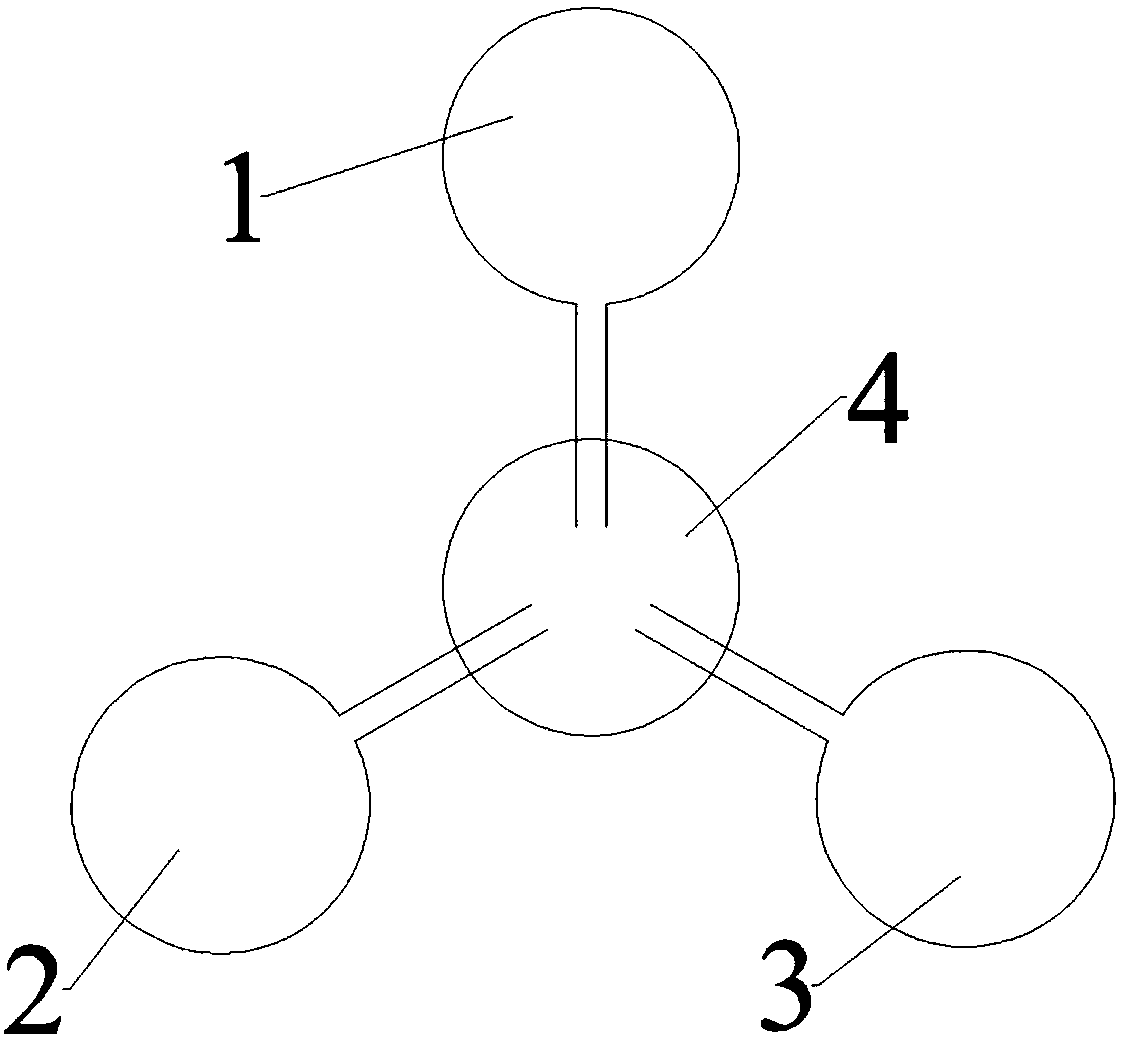

[0024] Step 2, divide the mixed solution into three equal parts, put them into the first reactor, the second reactor and the third reactor respectively, and check the temperature in the first reactor, the second reactor and the third reactor Maintained at 20°C, the first reactor, the second reactor and the third reactor communicate with the fourth reactor through the first liquid spray pipe, the second liquid spray pipe and the third liquid spray pipe respectively. A liquid spray pipe, the second liquid spray pipe and the third liquid spray pipe are respectively pro...

Embodiment 2

[0032] A preparation method of nanometer ATO powder, comprising:

[0033] Step 1, take by weighing antimony chloride and tin chloride according to the molar ratio of 1:10, dissolve with dehydrated alcohol, and add ethylene glycol, obtain mixed solution; Wherein, the use amount of dehydrated alcohol is the quality of tin chloride 30 times, the amount of ethylene glycol added is 200 times the mass of tin chloride;

[0034] Step 2, divide the mixed solution into three equal parts, put them into the first reactor, the second reactor and the third reactor respectively, and check the temperature in the first reactor, the second reactor and the third reactor Maintained at 40°C, the first reactor, the second reactor and the third reactor communicate with the fourth reactor through the first liquid spray pipe, the second liquid spray pipe and the third liquid spray pipe respectively, and the first A liquid spray pipe, the second liquid spray pipe and the third liquid spray pipe are re...

Embodiment 3

[0042]A preparation method of nanometer ATO powder, comprising:

[0043] Step 1, take by weighing antimony chloride and tin chloride according to the molar ratio of 1:10, dissolve with dehydrated alcohol, and add ethylene glycol, obtain mixed solution; Wherein, the use amount of dehydrated alcohol is the quality of tin chloride 25 times, the amount of ethylene glycol added is 150 times the mass of tin chloride;

[0044] Step 2, divide the mixed solution into three equal parts, put them into the first reactor 1, the second reactor 2 and the third reactor 3 respectively, and put the first reactor 1, the second reactor 2 and the third reactor The temperature in the reactor 3 is maintained at 35° C., and the first reactor 1, the second reactor 2 and the third reactor 3 communicate with each other through the first liquid spray pipe, the second liquid spray pipe and the third liquid spray pipe respectively. The fourth reaction kettle 4 is connected, and the first liquid spray pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com