A multi-layer film structure negative plate and its mixed solid-liquid electrolyte lithium battery

A technology of lithium battery and solid electrolyte membrane, which is applied in the direction of structural parts, battery electrodes, secondary batteries, etc., can solve the problems that limit the development and application of lithium batteries, the liquid electrolyte is volatile, and the volume expansion stress, etc., achieves simple structure and improved Ion transmission ability and high energy density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2-6

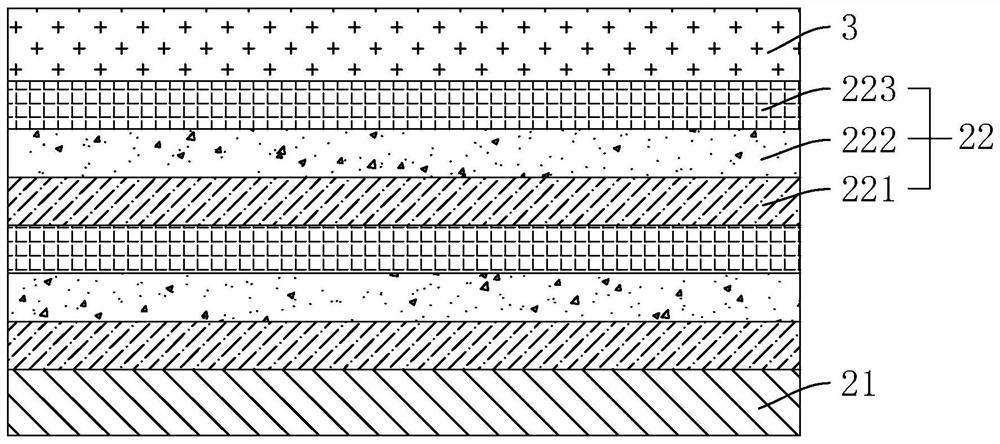

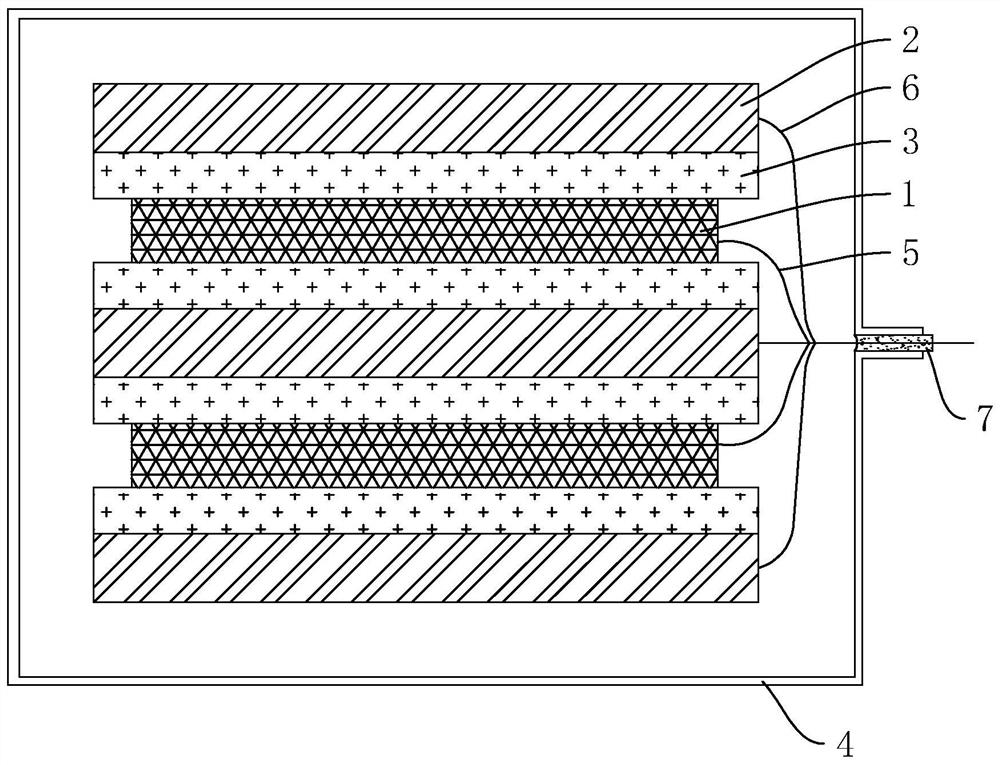

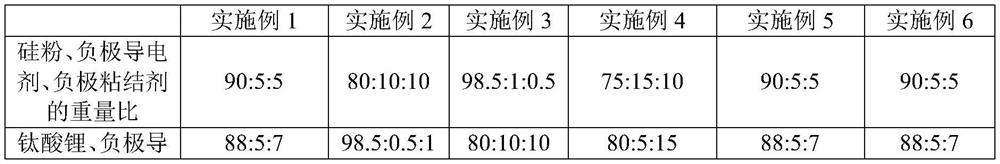

[0044] Embodiments 2-6 are all based on the method of Embodiment 1, and the parameters of the negative electrode sheet are adjusted, and the specific adjustments are shown in Table 1 below.

[0045] Table 1 The negative plate parameter table of embodiment 1-6

[0046]

[0047]

[0048] 1.3. Examples 7-11

[0049] Embodiments 7-11 are all based on the method of Embodiment 1, and the parameters of the lithium battery are adjusted, and the specific adjustments are shown in Table 2 below.

[0050] Table 2 Lithium storage battery parameter table of embodiment 1, 7-11

[0051]

[0052] 2. Comparative example

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com