Preparation method and application of a nitrogen-containing carbon material

A technology for nitrogen-carbon materials and raw materials, which is applied in the field of preparation of nitrogen-containing carbon materials, can solve problems such as equipment corrosion, and achieve the effects of avoiding corrosion, achieving significant effects and reducing significantly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

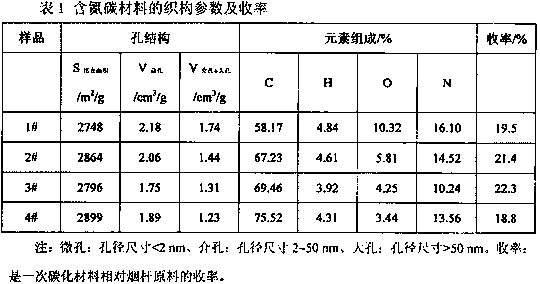

Embodiment 1

[0026] Put the tobacco rod raw material in an oven at 60°C and dry until the moisture content is below 5%, crush it to 20-40 mesh, weigh 10 g of the sample, and mix it with methanol aqueous solution (methanol concentration 5%wt) according to the solid-liquid volume ratio of 1:15 Mix and transfer to a ball mill jar, add 1.0 g of HY molecular sieve (10% of the weight of the tobacco rod) and mix at room temperature for 5 h at a ball mill speed of 300 rpm to obtain a feed solution. The feed liquid and the agate beads were separated and transferred to a high-pressure reactor, and reacted at 100 °C and 5 MPa for 24 h under a nitrogen atmosphere. The reaction solution was filtered while it was hot, washed three times with deionized water, and the filter residue was dried and then placed in a tube furnace for carbonization at 600°C for 5 hours under a nitrogen atmosphere to obtain a primary carbonized material. Soak the primary carbonized material in 200 ml of 1 M HNO 3 -0.5 M H 2 o...

Embodiment 2

[0028] Put the raw material of the tobacco stem in an oven at 80°C and dry until the moisture content is below 5%, crush it to 40-60 mesh, weigh 10 g of the sample, and mix it with propanol aqueous solution (propanol concentration 10%wt) according to the solid-liquid volume ratio of 1:5 Mix and transfer to a ball mill jar, add SO 3 0.5 g of H-MCM-41 mesoporous material (5% of the weight of the tobacco rod) was mixed at room temperature for 2 h at a ball milling speed of 200 rpm. The feed liquid and the agate beads were separated and transferred to a high-pressure reactor, and reacted at 200 °C and 5 MPa for 1 h under a nitrogen atmosphere. The reaction solution was filtered while it was hot, washed three times with deionized water, and the filter residue was dried and placed in a tube furnace for carbonization at 800 °C for 1 h in a nitrogen atmosphere to obtain a primary carbonized material. The obtained primary carbonized material was soaked in 200 ml of 4 MHNO 3 -2 M H 2...

Embodiment 3

[0030] Put the tobacco rod raw material in an oven at 100°C and dry until the moisture content is below 5%, crush it to 60-90 mesh, weigh 10 g of the sample, and mix it with ethanol aqueous solution (ethanol concentration 8%wt) according to the solid-liquid volume ratio of 1:10. Mix and transfer to a ball mill jar, add 2.0 g of HZSM-5 molecular sieve (20% of the weight of the tobacco rod) and mix at room temperature for 4 h at a ball mill speed of 400 rpm. The feed liquid and the agate beads were separated and transferred to a high-pressure reactor, and reacted at 150 °C and 12 MPa for 14 h under a nitrogen atmosphere. The reaction solution was filtered while it was hot, washed three times with deionized water, and the filter residue was dried and placed in a tube furnace for carbonization at 700 °C for 2 h under a nitrogen atmosphere to obtain a primary carbonized material. The resulting primary carbon material was soaked in 200 ml of 8 MHNO 3 -8 M H 2 o 2 Stir in the mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com