Polypyrrole/Ti3C2Tx/sulfur composite material

A composite material, polypyrrole technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve problems such as slow migration speed, reduced utilization of sulfur active materials, and safety issues of lithium-sulfur batteries, so as to improve lifespan, Reduces the effect of the shuttle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

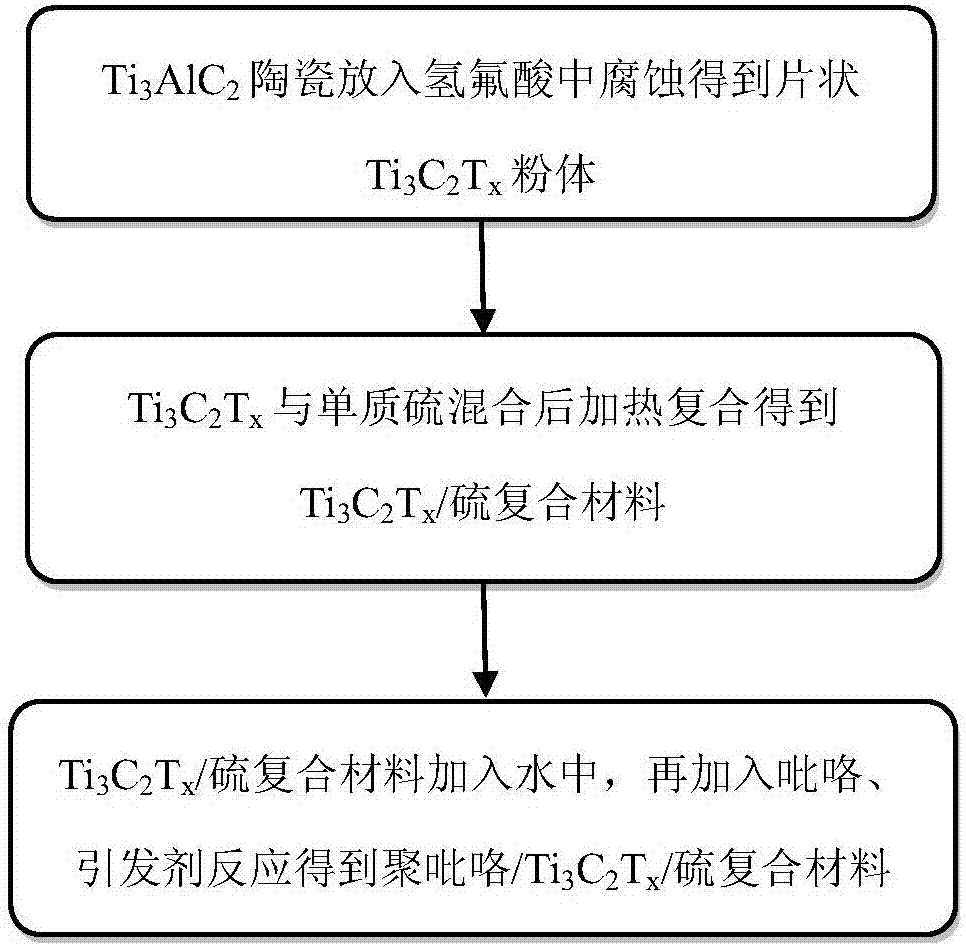

[0017] (1) Put Ti 3 AlC 2 The ceramic powder was corroded in hydrofluoric acid with a mass concentration of 20% for 24 hours. After corrosion, the solution was added to deionized water for centrifugation, and then the precipitate was dried to obtain stacked layered Ti. 3 C 2 T x Powder;

[0018] (2) Add 0.5g Ti 3 C 2 T x Mix the powder with 10g of elemental sulfur evenly, place it in a sealed reaction kettle, heat the reaction to 155°C in a nitrogen atmosphere, keep the temperature for 12h, cool to room temperature after the reaction is completed, and obtain Ti 3 C 2 T x / sulfur composites;

[0019] (3) Ti will be obtained 3 C 2 T x Add the / sulfur composite material into water and stir, then add 0.5g pyrrole and stir, then add 0.05g initiator azobisisobutyronitrile, stir, stand still, filter, and dry in vacuum to obtain polypyrrole / Ti 3 C 2 T x / sulfur composites.

Embodiment 2

[0021] (1) Put Ti 3 AlC 2 The ceramic powder was corroded in hydrofluoric acid with a mass concentration of 50% for 4 hours. After corrosion, the solution was added to deionized water for centrifugation, and then the precipitate was dried to obtain stacked layered Ti. 3 C 2 T x Powder;

[0022] (2) Put 2g Ti 3 C 2 T x The powder was uniformly mixed with 10g of elemental sulfur, placed in a sealed reaction kettle, heated to 165°C in a nitrogen atmosphere, and kept at a constant temperature for 5h. After the reaction was completed, it was cooled to room temperature to obtain Ti 3 C 2 T x / sulfur composites;

[0023] (3) Ti will be obtained 3 C 2 T x Add the / sulfur composite material into water and stir, then add 2g of pyrrole and stir, then add 0.02g of initiator dibenzoyl peroxide, stir, stand still, filter, and dry in vacuum to obtain polypyrrole / Ti 3 C 2 T x / sulfur composites.

Embodiment 3

[0025] (1) Put Ti 3 AlC 2 The ceramic powder was corroded in hydrofluoric acid with a mass concentration of 30% for 20 hours. After corrosion, the solution was added to deionized water for centrifugation, and then the precipitate was dried to obtain stacked layered Ti. 3 C 2 T x Powder;

[0026] (2) Add 1g Ti 3 C 2 T x Mix the powder with 10g of elemental sulfur evenly, place it in a sealed reaction kettle, heat the reaction to 160°C in a nitrogen atmosphere, keep the temperature for 10h, cool to room temperature after the reaction is completed, and obtain Ti 3 C 2 T x / sulfur composites;

[0027] (3) Ti will be obtained3 C 2 T x Add the / sulfur composite material into water and stir, then add 1g of pyrrole and stir, then add 0.05g of initiator ammonium persulfate, stir, stand still, filter, and dry in vacuum to obtain polypyrrole / Ti 3 C 2 T x / sulfur composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com