Auxiliary method and device for wire cut electrical discharge machining

A wire electric discharge and cutting technology, which is applied in the field of auxiliary methods and devices for wire electric discharge machining, can solve the problems of improper selection of vibration frequency and amplitude, reduced workpiece surface quality, reduced processing efficiency, etc., so as to reduce the negative impact. Small size, improved workpiece surface quality, and improved scour ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Processing environment: the wire cutting machine is a high-performance 5-axis CNC slow-moving wire-cut electric discharge machine tool, and the metal workpiece to be processed is a difficult-to-machine material Ti6Al4V with a thickness of 10 mm;

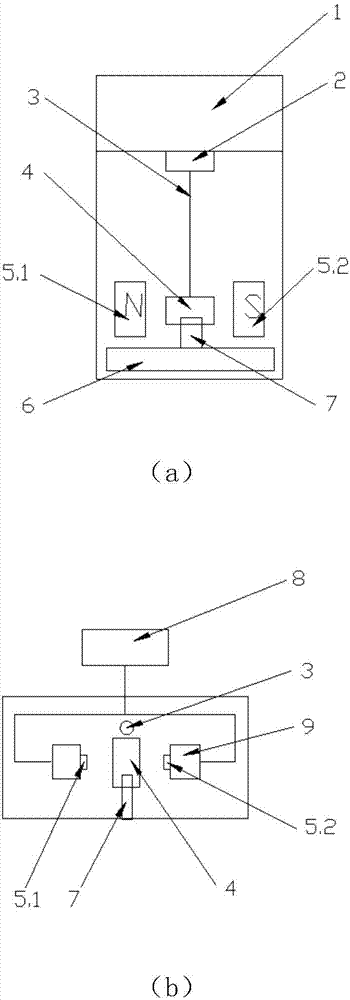

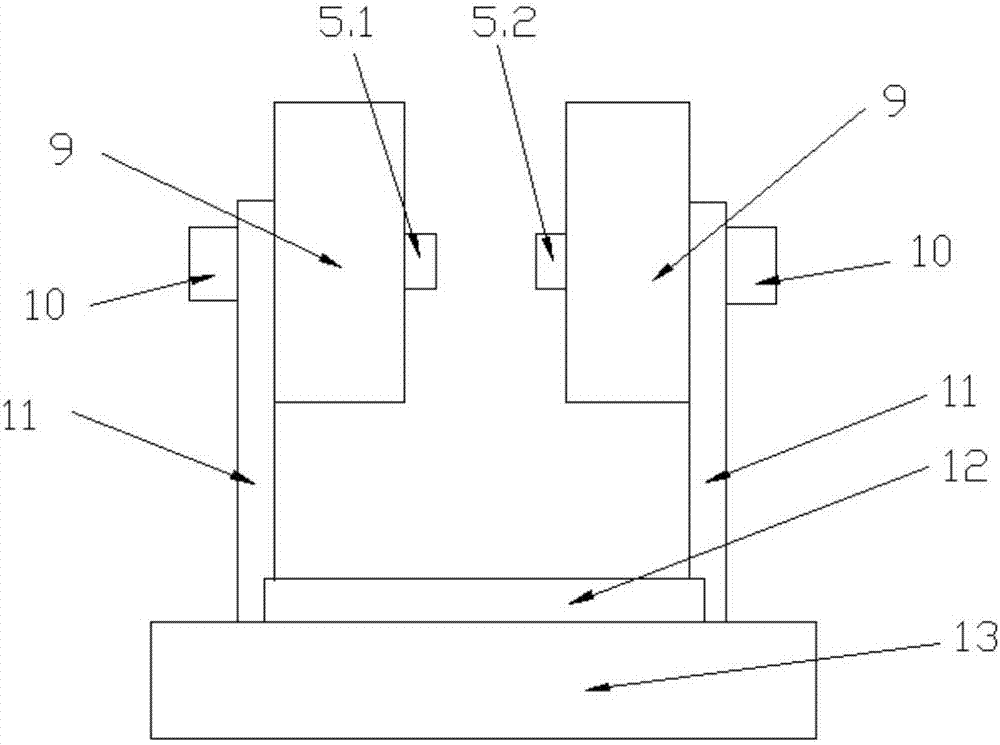

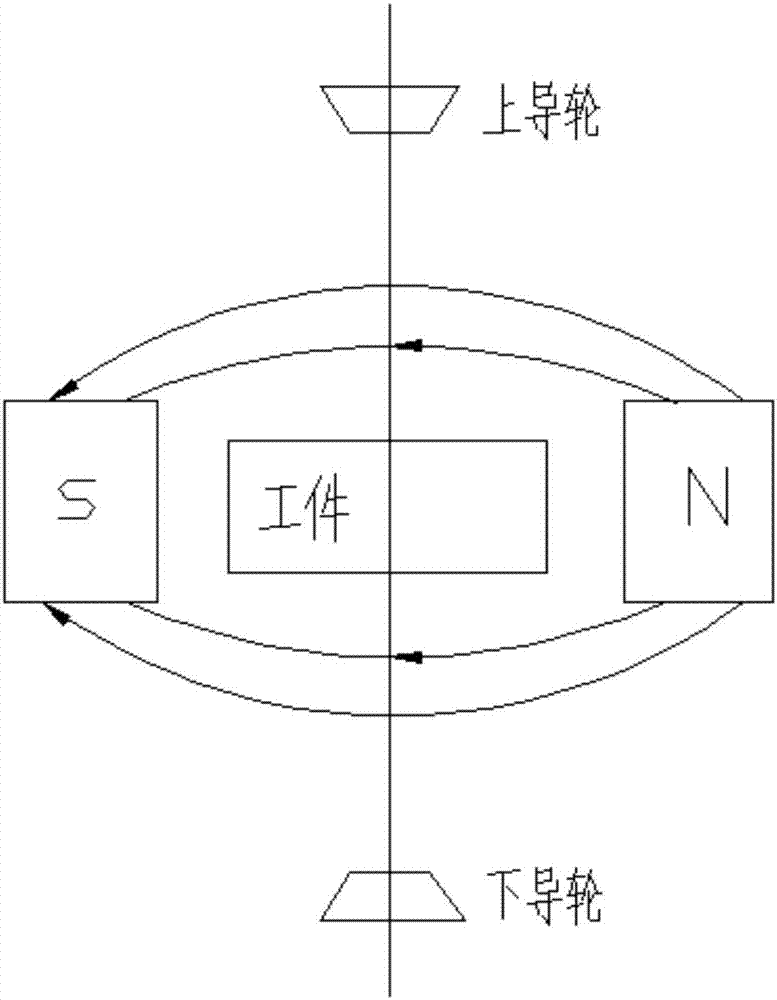

[0033] The pulse width of the pulse current provided by the CNC slow-moving WEDM machine tool is 22μs, and the current is 5A; the slit is cut with a length of 5mm; the DC excitation power supply of the auxiliary device used has the function of current overvoltage and overtemperature protection, and the resolution is 10mA , can provide DC current 0-10A, voltage 0-30V, output power 300W; the electromagnet of the auxiliary device includes magnetic poles, yokes (including vertical yokes and cross yokes), wire bags and column sleeves, all of which are made of industrial pure iron The distance between the wire packs is 80mm, the diameter of the pole head of the electromagnet is 50mm, the distance between the two poles is adjustable w...

Embodiment 2

[0037] Processing environment: the wire cutting machine is a high-performance 5-axis CNC slow-moving wire-cut electric discharge machine tool, and the metal workpiece to be processed is a difficult-to-machine material Ti6Al4V with a thickness of 10 mm;

[0038] The pulse width of the pulse current provided by the CNC slow-moving WEDM machine tool is 22μs, and the current is 5A; the slit is cut with a length of 5mm; the DC excitation power supply of the auxiliary device used has the function of current overvoltage and overtemperature protection, and the resolution is 10mA , can provide DC current 0-10A, voltage 0-30V, output power 300W; the electromagnet of the auxiliary device includes magnetic poles, yokes (including vertical yokes and cross yokes), wire bags and column sleeves, all of which are made of industrial pure iron The distance between the wire packs is 80mm, the diameter of the pole head of the electromagnet is 50mm, the distance between the two poles is adjustable w...

Embodiment 3

[0042] The difference between the processing environment of embodiment 3 and embodiment 1 is: the magnetic pole spacing of the electromagnet is 40mm, the magnetic induction intensity of the magnetic field generated by the auxiliary device is 400mT by adjusting the output current of the DC excitation power supply to 10A, and the numerical control slow-moving wire electric spark The pulse width of the pulse current provided by the wire cutting machine is 22 μs, the current is 2A, and the others are the same as those in Embodiment 1.

[0043] After adopting the auxiliary device and method provided in this embodiment, the material removal rate is 0.083mm 3 / min, the surface roughness of the obtained workpiece is 0.52 μm; and without using the auxiliary device and method provided in this embodiment, the material removal rate is 0.017mm 3 / min, the surface roughness of the obtained workpiece is 0.58 μm; in contrast, the use of the auxiliary device and method provided by this embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| material removal rate | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com