Lithium ion battery with high energy density

A lithium-ion battery, high energy density technology, applied in batteries, battery electrodes, secondary batteries, etc., can solve the problems of low density, high safety hazards, poor uniformity, etc., to achieve high density, process controllable and consistent strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

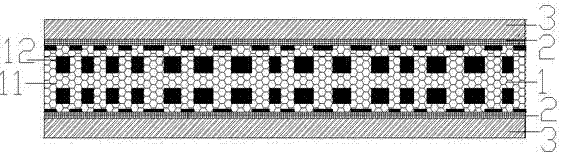

Image

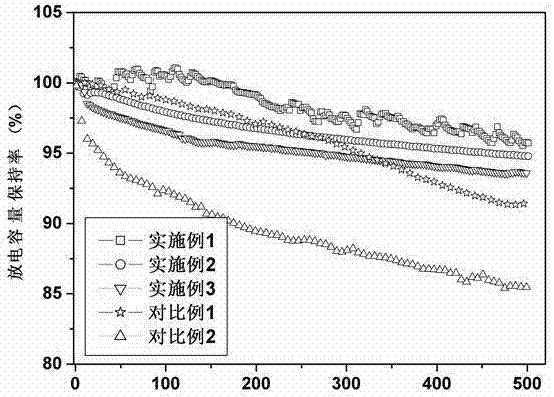

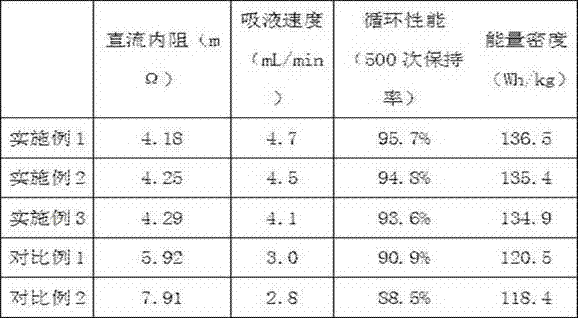

Examples

Embodiment 1

[0025] Ⅰ. Preparation of hard carbon composite electrodes:

[0026] First, weigh 85g of hard carbon material and add it to 15g of polyvinylidene fluoride and 50g of N-methylpyrrolidone, stir evenly to obtain a sticky colloid, and press it onto the surface of foamed copper, and obtain a hard carbon composite electrode A after drying ;

[0027] Ⅱ. Electrodeposition of hard carbon composite electrodes:

[0028] Add 144g of lithium difluorooxalate borate to 1000ml of ethyl methyl carbonate to configure a 0.1mol / L solvent, then use the hard carbon composite electrode A as the working electrode, the platinum electrode as the counter electrode, and the saturated calomel as the reference electrode, and Cyclic voltammetry (scanning speed 0.5mV / s, voltage range -2V-2V, scanning for 20 cycles) deposited lithium salt on the surface of its hard carbon composite electrode A, and finally obtained a hard carbon composite electrode B containing lithium difluorooxalate borate ;

[0029] Ⅲ. H...

Embodiment 2

[0032] Ⅰ. Preparation of hard carbon composite electrodes:

[0033] First, weigh 80g of hard carbon material and add it to 20g of polyvinylidene fluoride and 50 parts of N-methylpyrrolidone, stir evenly to obtain a sticky colloid, and press it onto the surface of copper foam. After drying, a hard carbon composite electrode A is obtained. ;

[0034] Ⅱ. Electrodeposition of hard carbon composite electrodes:

[0035] Add 94g of lithium tetrafluoroborate to 1000ml of ethyl methyl carbonate to configure a 0.1mol / L solvent, then use the hard carbon composite electrode A as the working electrode, the platinum electrode as the counter electrode, and the saturated calomel as the reference electrode, and use The constant voltage method (voltage 1.8V, time 20min) deposits lithium salt on the surface of the hard carbon composite electrode A, and finally obtains the hard carbon composite electrode B containing lithium tetrafluoroborate;

[0036] Ⅲ. Hard carbon composite electrode coating...

Embodiment 3

[0039] Ⅰ. Preparation of hard carbon composite electrodes:

[0040] First, weigh 90g of hard carbon material and add it to 10g of polyvinylidene fluoride and 50 parts of N-methylpyrrolidone, stir evenly to obtain a sticky colloid, and press it onto the surface of copper foam. After drying, a hard carbon composite electrode A is obtained. ;

[0041] Ⅱ. Electrodeposition of hard carbon composite electrodes:

[0042] Add 144g of lithium difluorooxalate borate to 1000ml of ethyl methyl carbonate to configure a 0.1mol / L solvent, then use the hard carbon composite electrode A as the working electrode, the platinum electrode as the counter electrode, and the saturated calomel as the reference electrode, and A constant current method (current density 20mA / cm2, time 30min) was used to deposit lithium salt on the surface of the hard carbon composite electrode A, and finally a hard carbon composite electrode B containing difluorooxalate lithium borate was obtained;

[0043] Ⅲ. Hard car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com