A kind of preparation method of iron oxide product

An iron oxide and product technology, applied in the field of non-ferrous smelting, can solve the problems of environmental pollution, waste of resources, occupation of land, etc., and achieve the effect of shortening the purification process and efficient recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

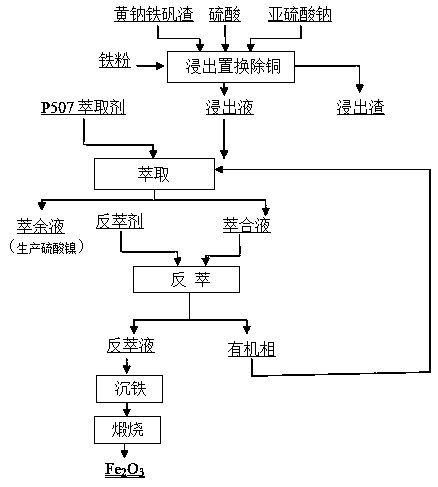

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of iron oxide product, comprising the following steps:

[0033] A. Jarosite slag leaching: Add jarosite slag and dilute sulfuric acid in a reaction kettle with a mechanical stirring and heating device according to the solid-to-liquid volume ratio of 1:5, react for 0.5h, dilute sulfuric acid [H + ] The concentration is 82g / L, and the reaction temperature is controlled to be 80°C; analyze the Fe content in the slurry liquid, according to the Fe content of the slurry liquid 3+ Add sodium sulfite to 1.1 times the concentration and react for 2 hours; analyze the Cu content in the slurry, according to the Cu content of the slurry 2+ Add iron powder at 1.2 times the concentration and react for 0.5h. After the reaction is completed, the slurry in the kettle is separated from solid to liquid.

[0034] B. Extraction of leaching solution: P 507 After the extraction agent and solvent oil (sulfonated kerosene) are mixed at a ratio of 1:3, NaOH solution with a...

Embodiment 2

[0039] A preparation method of iron oxide product, comprising the following steps:

[0040] A. Jarosite slag leaching: Add jarosite slag and dilute sulfuric acid in a reaction kettle with a mechanical stirring and heating device according to a solid-to-liquid ratio of 1:4, react for 1 hour, dilute sulfuric acid [H + ] The concentration is 85g / L, and the reaction temperature is controlled to be 82°C; analyze the Fe content in the slurry liquid, according to the Fe content of the slurry liquid 3+ 1.0 times the concentration, add sodium sulfite and react for 1.5h; analyze the Cu content in the slurry, according to the Cu content of the slurry 2+ Add iron powder at 1.1 times the concentration, and react for 1 hour. After the reaction is completed, the slurry in the kettle is separated from solid to liquid.

[0041] B. Extraction of leaching solution: P 507 After the extraction agent and solvent oil (sulfonated kerosene) are mixed at a ratio of 1:3, NaOH solution with a mass conc...

Embodiment 3

[0046] A preparation method of iron oxide product, comprising the following steps:

[0047] A. Jarosite slag leaching: add jarosite slag and dilute sulfuric acid in a reaction kettle with a mechanical stirring and heating device according to a solid-to-liquid ratio of 1:5, react for 0.5h, dilute sulfuric acid [H + ] The concentration is 84g / L, and the reaction temperature is controlled to be 84°C; analyze the Fe content in the slurry liquid, according to the Fe content of the slurry liquid 3+ Add sodium sulfite to 1.2 times the concentration and react for 2 hours; analyze the Cu content in the slurry, according to the Cu content of the slurry 2+ Add iron powder at 1.2 times the concentration and react for 0.5h. After the reaction is completed, the slurry in the kettle is separated from solid to liquid.

[0048] B. Extraction of leaching solution: P 507 After the extraction agent and solvent oil (sulfonated kerosene) are mixed at a ratio of 1:3, NaOH solution with a mass con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com